tions,

Table 1

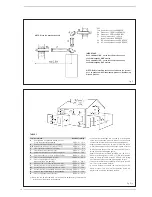

gives the minimum distances

to be observed, with reference to the type

of building shown in fig. 5/a.

2.6

SEPARATE PIPES ø 80

A special kit may be used to separate the

flue gas outlet from the air intake. The

intake may be installed to the right or left of

the flue gas outlet. It is essential that a flue

gas analysis test point is made available

directly above the boiler. Refer to fig. 8 for

positioning.

The maximum overall length of

the intake and exhaust ducts depends on

the head losses of the single fittings

installed (excluding the doublers) and

must not be greater than 15,5 mm H

2

O.

For head losses in the fittings, refer to

Table

2

.

2.6.1

Separate pipe accessories

Kit code 8089911 is supplied for this pur-

pose (fig. 9).

2.8

ELECTRICAL CONNECTION

Wiring external to the appliance must be in

accordance with the current I.E.E Wiring

regulations (BS 7671) for electrical installa-

tion and any local regulations, which apply.

Connection to the mains supply must facili-

tate complete electrical isolation of the

appliance. A 3A fused double pole switch

having a 3 mm contact separation in both

poles and serving only the appliance (and its

external controls) may be used.

The boiler is supplied with an electric cable.

15

5

Ø 80

Ø 80

10

5

P

L

CA

K

Z

CS

KEY

CA

Inlet

CS

Outlet

Fig. 8

DEWY 30/130 HE FS

K mm

348

L mm

263

P mm

230

Z mm

315

1

2

3

4

5

3

KEY

1 Blind flange

2 Flue gas duct flange

3 Fixing screw

4 Gasket ø 125/95

5 Intake duct collar

Fig. 9

TABLE 2

Accessories ø 80

Head loss (mm H

2

O)

Inlet

Outlet

Roof outlet

90° elbow MF

0.30

0.50

–

45° elbow MF

0.20

0.40

–

Extension L. 1000 (horizontal)

0.20

0.40

–

Extension L. 1000 (vertical)

0.30

0.30

–

Outlet terminal

–

0.40

–

Inlet terminal

0.10

–

–

Doubler fitting

0.30

–

–

Roof outlet terminal L. 1381

–

–

0.60

13