Installation, use and maintenance manual

MANUAL CODE: 6328407

Page 40 / 148

1.3

Copyright

These instructions contain information protected

by copyright. Do not photocopy, duplicate,

translate or store these usage instructions on

storage media either in whole or in part, without

prior authorisation from the Supplier. Any violations

shall be subject to compensation for damages. All

rights, including those resulting from the issuance of

patents or registration of utility models, are

reserved.

1.4

Operating principle

The appliances in the 1.6 kW range produce

domestic hot water mainly using heat-pump

technology. A heat pump transfers thermal energy

from a source at a lower temperature to a source

at a higher temperature, and vice versa (using

heat exchangers).

The appliance uses a hydraulic circuit composed

of a compressor, an evaporator, a capacitor and

a thermal expansion valve. A refrigerant fluid/gas

flows in the circuit (see section 4.6).

The compressor creates a difference in pressure

inside the circuit, which creates a thermodynamic

cycle. The compressor aspirates the refrigerant

fluid through an evaporator, where it evaporates

at low pressure absorbing heat, compresses it and

forces it towards the capacitor, where the fluid

condenses at high pressure, releasing the

absorbed heat. The fluid then passes through a

capillary tube and, decreasing in pressure and

temperature, starts to vaporise and enters the

evaporator again, restarting the cycle.

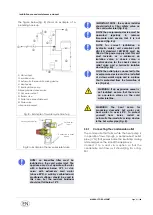

Fig. 5 – Operating principle

The appliance operating

principle is as follows

I-II:

the refrigerant fluid aspirated by the

compressor runs inside the evaporator and, while

evaporating, absorbs the ecological heat

provided by the air.

At the same time, the air in the space is aspirated

by the appliance, thanks to the fan. As it passes on

the finned battery of the evaporator, the air

releases its heat;

II-III:

the refrigerant gas passes inside the

compressor and there is an increase in pressure

which raises the temperature, turning the gas into

overheated vapour;

III-IV:

in the capacitor, the refrigerant gas releases

its heat in the water in the tank (boiler). This

exchange process transforms the refrigerant from

an overheated vapour into a liquid state,

condensing at a constant pressure and dropping

in temperature;

IV-I:

the refrigerant liquid passes through the

capillary tube, quickly dropping both in pressure

and temperature. It partially vaporises, returning to

the initial pressure and temperature conditions. The

thermodynamic cycle can now start again.

Ecological

heat

Capacitor

Air

Evaporator

Fan

Compressor

Capillary

tube

Tank

Cold water

Hot water

Electrical heat

Summary of Contents for ECOMAXI 160 ErP

Page 147: ......