23

3.3

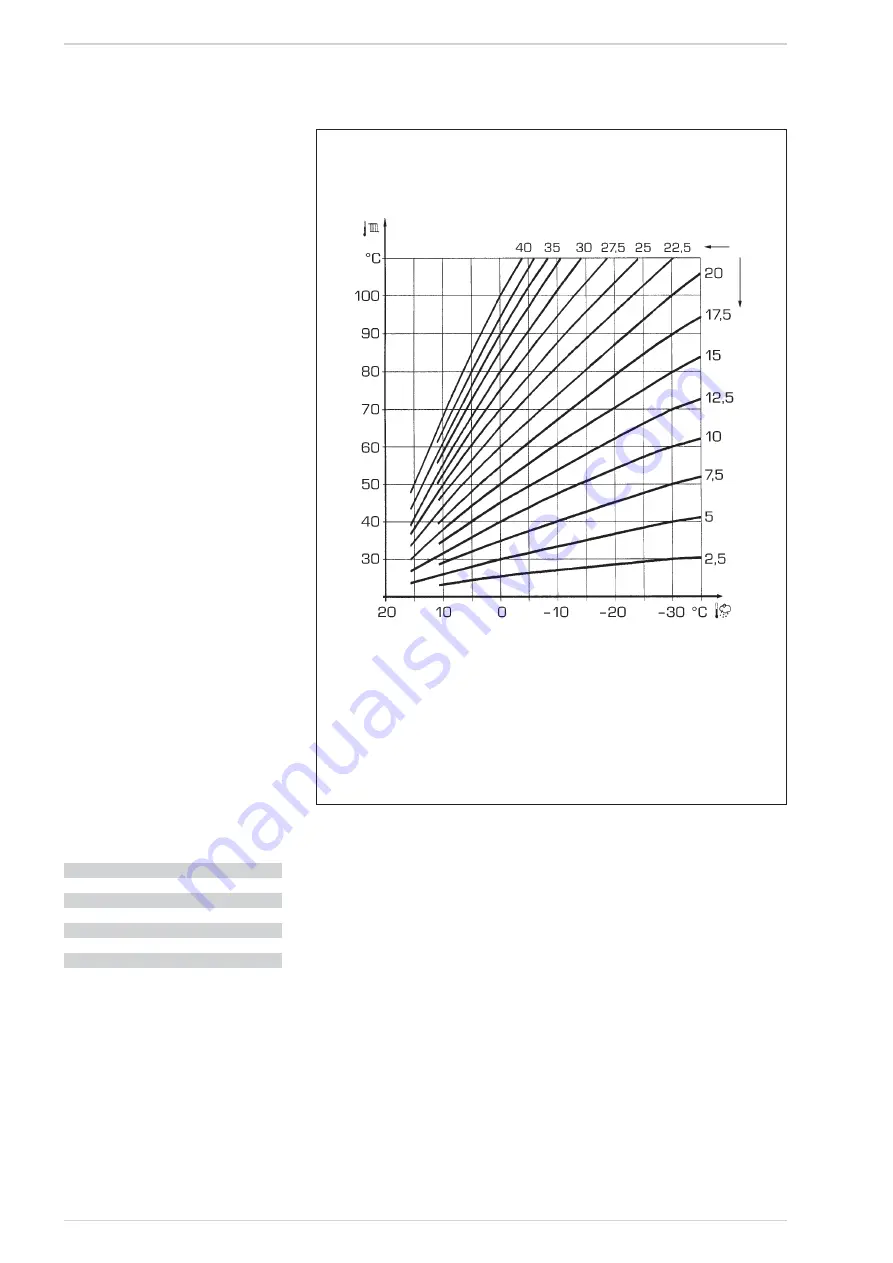

EXTERNAL SENSOR

If there is an external sensor, the heating

settings SET can be taken from the climatic

curves according to the external tempera-

ture and, in any case, limited to with the

range values described in point 3.2 (para-

meters PAR 13 and PAR 14).

The climatic curve to be set can be selected

from a value of 3 and 40 (at step 1).

Increasing the steepness of the curves of

fig. 11 will increase the output temperature

as the external temperature decreases.

3.4

BOARD FUNCTIONING

The electronic board has the following

functions:

– Antifreeze protection of the heating cir-

cuits.

– Ignition and flame detection system.

– Control panel setting for the power and

the gas for boiler functioning.

– Anti - jamming for the pump which is fed

for a few seconds (10”) after 48 hours of

inactivity.

– Chimney sweep function which can be

activated from the control panel.

– Temperature which can be shifted with

the external sensor connected.

– Automatic regulation of the ignition

power and maximum heating.

Adjustments are managed automatically

by the electronic card to guarantee maxi-

mum flexibility in use of the system.

3.5

TEMPERATURE

DETECTION PROBE

Table 6

gives the values of the electrical

resistance ( ) obtained on the heating sen-

sor according to the variations in tempera-

ture.

When the heating sensor (SM1/SM2) is

interrupted, the boiler will not function.

3.6

ELECTRONIC IGNITION

Ignition and flame detection is controlled by

a single electrode on the burner which gua-

rantees reaction in the case of accidental

extinction or lack of gas within one second.

3.6.1

Functioning cycle

Burner ignition should occur within 10

seconds of the opening of the gas valve. If

after three attempts the ignition is not

detected the boiler will lockout (ALL 06):

–

Lack of gas

The ignition electrode will discharge for a

maximum of 10 seconds. If after three

attempts the ignition is not detected the

boiler will lockout (ALL 06). This can hap-

pen the first time a boiler is switched on,

or after long periods of inactivity. It can

also be caused by a closed gas cock or a

gas valve not operating.

–

No ionisation

The boiler will spark for 10 seconds, if

after 3 attempts the ionisation is not

detected, the boiler will lockout (ALL 06).

This could be due to a poor connection or

break in the ionisation cable. Check also

that the cable is not shorted, badly worn

or distorted.

In the case of a sudden loss of voltage, the

burner will immediately switch off. When

the voltage is restored, the boiler will auto-

matically start up again.

3.7

AIR PRESSURE SWITCH

The pressure switch is calibrated by the

manufacturer at the following values:

0.62 - 0.72 H

2

O f or ver s.

“25 HE -

EV/SYSTEM 25 HE -EV”

0.45 - 0.55 H

2

O for vers.

“30 HE -EV”

,

which can guarantee boiler functioning pro-

vided that the inlet and exhaust pipe is

within the maximum length allowed.

3.8

HEAD AVAILABLE

TO SYSTEM

Residual head for the heating system is

shown as a function of rate of flow in the

graph in fig. 12.

To obtain the maximum head available to

the system, turn off the by-pass by turning

the union to the vertical position (fig. 13).

Fig. 11

ATTENTION: curves are calculated at an ambient temperature of

20°C. The user can act on the boiler controls to change the environ-

ment set for which the bend has been calculated by ±5°C.

TABLE 6

Temperature (°C)

Resistance (

Ω

)

20

12.090

30

8.313

40

5.828

50

4.161

60

3.021

70

2.229

80

1.669