2.1

BOILER ROOM

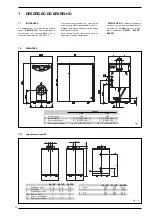

The boiler room should feature all the char-

acteristics required by standards governing

liquid fuel heating systems.

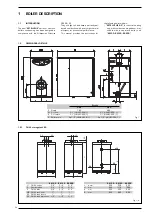

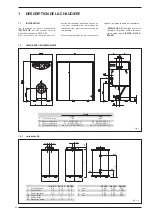

2.2

BOILER ROOM

DIMENSIONS

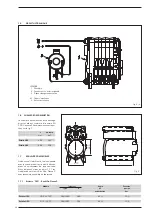

Position the boiler body on the foundation

bed, which should be at least 10 cm high.

The body should rest on a surface allowing

shifting, possibly by means of sheet metal.

Leave a clearance between the boiler and

the wall of at least 0.60 m, and between the

top of the casing and the ceiling of 1 m

(0.50 m in the case of boilers with incorpo-

rated D.H.W. tank).

The ceiling height of the boiler room should

not be less than 2.5 m.

2.3

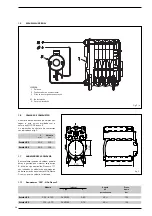

CONNECTING

UP SYSTEM

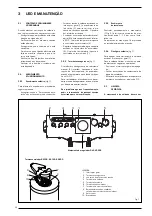

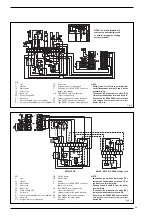

When connecting up the water supply to

the boiler, make sure that the specifications

given in fig. 1 are observed.

All connecting unions should be easy to dis-

connect by means of tightening rings.

A closed expansion tank system must be

used.

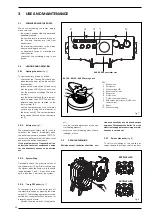

2.3.1

Filling the

water system

Before connecting the boiler, thoroughly

flush the system to eliminate scale which

could damage the appliance.

Filling must be done slowly to allow any air

bubbles to be bled off through the air valves.

In closed-circuit heating systems, the cold

water filling pressure and the pre-charging

pressure of the expansion vessel should be

no less than or equal to the height of the

water head of the installation (e.g. for water

head of 5 meters, the vessel pre-charging

pressure and installation filling pressure

should be at least 0.5 bar).

2.3.2

Characteristics

of feedwater

Water supplying the heating circuit must

be treated in accordance with UNI-CTI

8065 standards.

It is absolutely essential to treat water in

the heating system in the following cases:

– For extensive systems (with high con-

tents of water).

– Frequent addition of water into the

system.

– Should it be necessary to empty the sys-

tem either partially or totally.

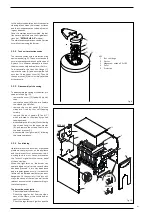

2.3.3

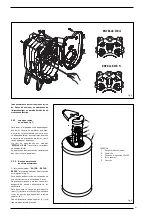

D.H.W. storage tank

The

“ESTELLE HE”

boilers may be matched

with the separate boiler units

“BA100-

BA150 -BA200”

.

The glass enamelled D.H.W. storage tank

comes with a magnesium anode to protect

the boiler and an inspection flange for

checking and cleaning.

The magnesium anode must be checked

annually and replaced if it is worn.

Fit a safety valve calibrated to 6 bar on the

tubing of the cold water supply to the boiler

unit. An case the system pressure is exces-

sive fit an appropriate pressure reducer. If

the safety valve calibrated to 6 bar fre-

quently intercepts, fit an expansion vessel

with a capacity of 8 litres and a maximum

pressure of 8 bar. The tank should be of the

membrane type, made of natural rubber

“caoutchouc”, which is suitable for foods.

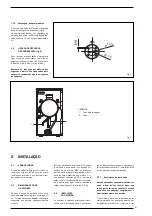

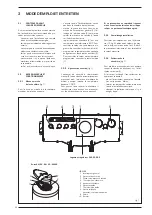

2.4

CONNECTING UP FLUE

The flue is of fundamental importance for

the proper operation of the boiler; if not

installed in compliance with the standards,

starting the boiler will be difficult and there

will be a consequent formation of soot, con-

densate and encrustation.

The flue used to expel combustion products

into the atmosphere must meet the follow-

ing requirements:

– be constructed with waterproof materi-

als, and resistant to smoke temperature

and condensate;

– be of adequate mechanical resilience and

of low heat conductivity;

– be perfectly sealed to prevent cooling of

the flue itself;

– be as vertical as possible; the terminal

section of the flue must be fitted with a

static exhaust device that ensures con-

stant and efficient extraction of products

generated by combustion;

– to prevent the wind from creating pres-

sure zones around the chimney top

greater than the uplift force of combus-

tion gases, the exhaust outlet should be

at least 0.4 m higher than structures

adjacent to the stack (including the roof

top) within 8 m;

– have a diameter that is not inferior to

that of the boiler union: square or rec-

tangular-section flues should have an

internal section 10% greater than that of

the boiler union;

– the useful section of the flue must con-

form to the following formula:

S

resulting section in cm

2

K

reduction coefficient for liquid fuels:

– 0.045 for firewood

– 0.030 for coal

– 0.024 for light oil

– 0.016 for gas

P

boiler input in kcal/h

H

height of flue in meters, measured

from the flame axis to the top of the

flue reduced by:

– 0.50 m for each change of direc-

tion of the connection union

between boiler and flue;

– 1.00 m for each metre of union

itself.

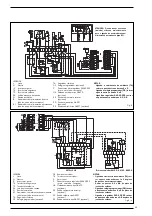

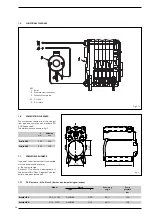

2.5

ELECTRICAL CONNECTION

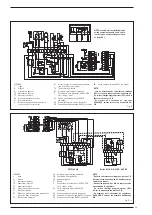

The boiler is fitted with an electricity cable,

and requires a 1ph - 230V - 50Hz power

supply through the main switch protected

by fuses. The room thermostat (required

for enhanced room temperature control)

should be installed as shown in fig. 6.

Connect the burner with the cable supplied.

NOTE: Device must be connected to an

efficient earthing system.

SIME declines all responsibility for injury

caused to persons due to failure to earth

the boiler.

Always turn off the power supply before

doing any work on the electrical panel.

2.5.1

RVA 43.222 climat controller

All functions of the boiler may be controlled

using the contr oller, optional code

8096303, which is supplied with an outdoor

temperature probe (SE) and a boiler immer-

sion probe (SC). The controller is installed in

the control panel in place of the relating

cover (fig. 7).

The controller is to be connected to an addi-

tional series of low voltage connectors for

connection of the room temperature control

unit (the connectors are supplied in a bag

inside the control panel). The probe bulb of

the external hot water tank, if any, (SS) code

6277110, must be inserted in the hot water

tank sheath, while the bulb of the boiler

probe (SC) must be inserted in the boiler

sheath. When assembling the outdoor tem-

perature probe, follow the instructions provi-

ded in the probe package. Refer to fig. 6 for

wiring instructions.

IMPORTANT: To make sure that the unit

works properly, set the boiler control ther-

mostat as high as it will go.

2.5.2

Electrical connection

to the BA boiler unit

To connect the boiler to the boiler unit pro-

ceed with the following operations:

– remove the casing lid of the boiler and

the back protection of the control panel

in order to have access to the terminal

board of the boiler;

– remove the protection of the boiler unit

to have access to the terminal board of

the boiler unit (fig. 7);

– connect the cables as shown in the dia-

gram (fig. 6/a).

38

P

S = K

√

H

2

INSTALLATION

Summary of Contents for ESTELLE HE

Page 1: ...IT ES ENG FR SL BE GR DE PT RO RUS Estelle HE CERTIFICAZIONE DEL SISTEMA DI QUALITA AZIENDALE ...

Page 116: ......

Page 118: ......

Page 119: ......