92

USER INSTRUCTIONS

WARNINGS

–In case of fault and/or incorrect equipment operation, deactivate it, without making any repairs or taking any direct

action. Contact the authorised technical staff.

–The installation of the boiler and any servicing or maintenance job must be carried out by qualified personnel. Under

no circumstances, the devices sealed by the manufacturer can be tampered with.

–It is absolutely prohibited to block the intake grilles and the aeration opening of the room where the equipment is

installed.

LIGHTING AND OPERATION

BOILER IGNITION

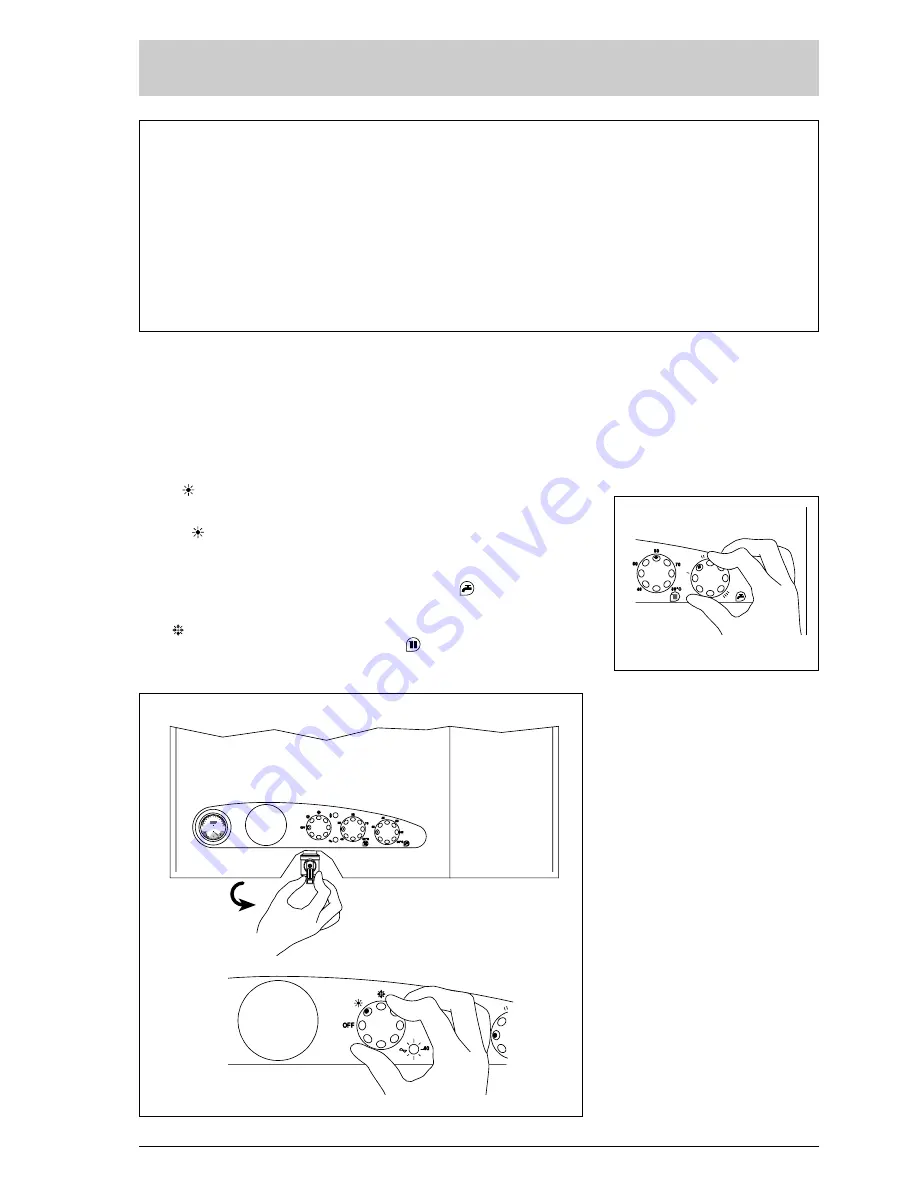

(fig. 1)

Open the gas valve and light the appliance

by turning the rotary switch to summer

position

. The green led indicates that

electricity is being supplied to the appliance.

– With the rotary switch in the summer

position

, the boiler will start-up upon

demand for domestic hot water, and run

at full power to reach the selected tempe-

rature. The gas feeding pressure will then

automatically vary to ensure that the

required temperature is kept constant.

–With the rotary switch in the winter posi-

tion

, once the boiler has reached the

value set on the heating potentiometer, it

will start to modulate in automatically in

order to supply the required power out-

put to the system.

The operation of the boiler will be stop-

ped through the intervention of the ther-

mostat or timer.

TEMPERATURES ADJUSTMENT

(fig. 2)

–The D.H.W. temperature can be adju-

sted by turning the knob of the D.H.W.

potentiometer

which has a range of

between 40 to 60°C (fig. 2).

–The C.H. temperature can be adjusted by

turning the knob of the C.H. potentiome-

ter

which has a range of between 40

to 80°C. To ensure optimal boiler effi-

ciency at all times, we recommend not to

drop below a minimum working tempera-

ture of 50°C.

TURNING THE BOILER OFF

(fig. 1)

To turn the boiler off place the rotary switch

on the

OFF

position. If the boiler is not going

to be used for a lengthy period it is advised

to turn off the electricity supply, close the

gas cock, and if low temperatures are fore-

seen, empty the boiler and the hydraulic

system to avoid breakage in the tubes due

to the freezing of the water.

GAS CONVERSION

Should it be necessar y t o conver t the

appliance to a different gas from the one

for which the boiler has been equipped,

approach the technical staff.

CLEANING AND MAINTENANCE

Preventive maintenance and checking of

the efficient operation of the equipment

and safety devices must be carried out

exclusively by the authorized technical

staff. The boiler is supplied with an elec-

tric cable. Should this require replace-

ment, contact exclusively an authorised

technical staff.

APRE

0

30

60

90

120

bar

°

C

0

3

4

1

Fig. 1

Fig. 2

OPEN