SIME FORMAT WALL HUNG BOILERS

MODEL 34i AND MODEL 34e

REF: INSTALLATION INSTRUCTIONS

19/02/04

10

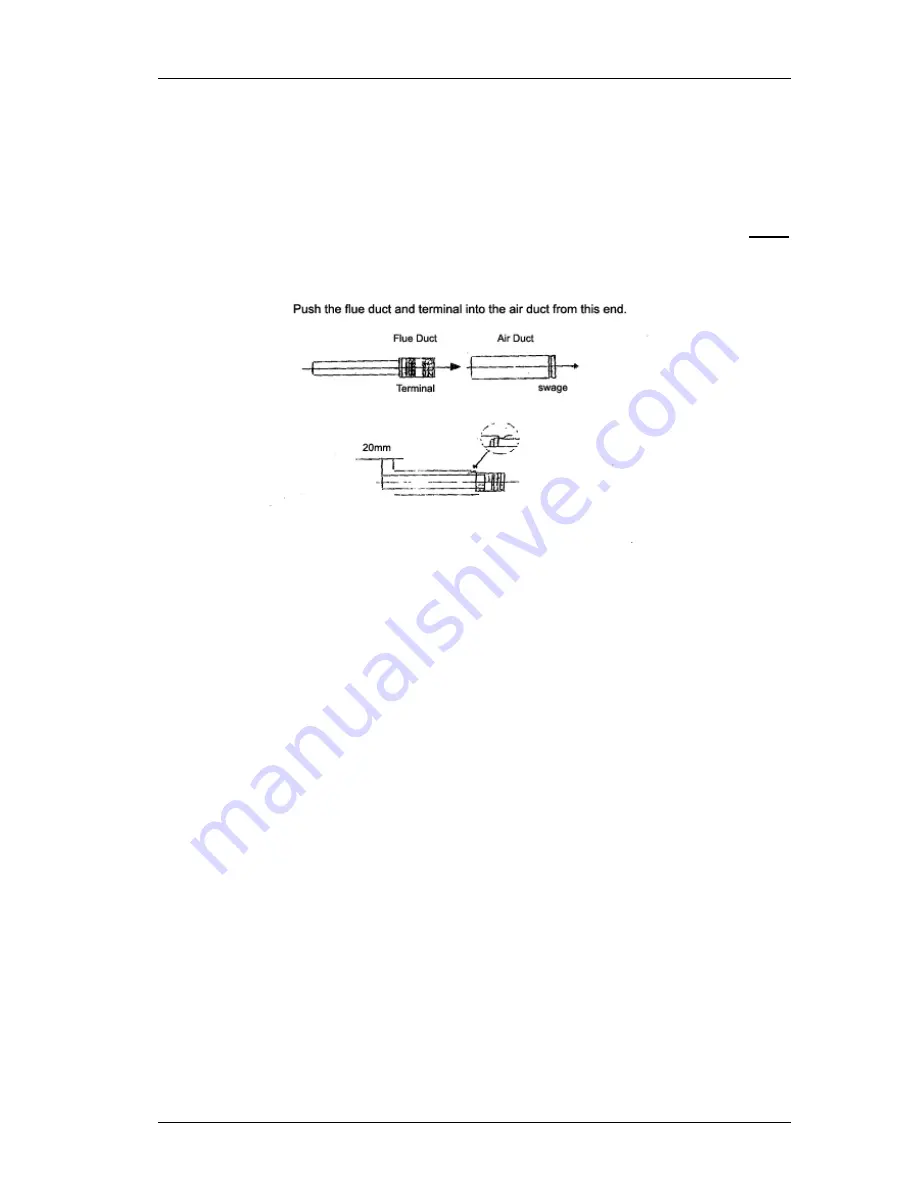

Cut square at this dimension and remove all burrs and

sharp edges.

f)

Refit the inner duct (see Fig. 6) and cut square this duct

20mm longer than the outer duct. Remove all burrs and

sharp edges.

Fig 6

g)

Fit outer seal in the swage next to the terminal, and slide

the assembly through the wall to clear the outer seal. Fit the inner seal and junction

collar to the outer duct.

h)

Ensure that the sealing ring is in place in the elbow and fit

inner duct and outer duct to the elbow.

i)

Locate the joining clamp and tighten, using screws

provided.

j)

Locate the gasket in the boiler flue outlet and pull back

assembly to locate the elbow. Fit four (4) screws provided

and tighten.

2.3.4) Side Wall Outlets

a)

Extension ducts are available for this application. The flue

elbow should be fitted to the boiler.

b)

In this case, the cut length of the outer duct Z = X + Y + 20.

Where

X = wall thickness

Y = distance from inner face of the wall to the

front edge of the elbow.

c)

It is recommended that, to drain any condensate, a fall of

5mm/meter length be provided.