13

2.9.1

Pump

The available head shown in fig. 5 is that in excess of the

appliance hydraulic resistance, i.e. that available for the

system at any given heating load up to the maximum output in

C.H. mode. Never reduce the pump speed below maximum as

this will reduce D.H.W. output. The pump speed is indicated on

the side of the pump speed selector switch (if fitted).

2.9.2 System volume (total water content)

The following Table gives the maximum system volume that

the integral expansion vessel can sustain under different

charge pressure conditions.

If the system volume exceeds that shown, an additional

expansion vessel must be fitted and connected to the heating

system primary return pipe as close as possible to the

appliance.

If an extra vessel is required, ensure that the total capacity of

both vessels is adequate. Further details are available in the

current issues of BS5449 and BS6798.

NOTE: If the pressure gauge indicates 2.65 bar or greater

when the appliance is at maximum temperature with all

radiators in circulation an extra expansion vessel is

required.

2.9.3 Pressure gauge

A pressure gauge is mounted on the appliance facia panel.

2.9.4 Safety valve

A safety valve set at 3 bar (43.5 psi) is fitted to the appliance

and a discharge pipe is routed to outside of the appliance.

This discharge pipe should be extended to terminate safely

away from the appliance and where a discharge would not

cause damage to persons or property but would be detected.

The pipe should be able to withstand boiling water, be a

minimum of 15 mm in diameter, and installed with a

continuous fall.

2.10

D.H.W. SYSTEMS

– Check that the mains supply pressure is within the

prescribed limits (1.3 point).

If necessary, a pressure reducing valve should be fitted to

the mains supply before the D.H.W. inlet connection.

– A maximum D.H.W. flow rate of:

11.4 l/m (3.0 gpm) for

“FORMAT 80 B”

and 14.7 l/m (3.9

gpm) for

“FORMAT 100 B”

is recommended.

Higher flow rates will not damage the appliance but may

lower the water temperature below an acceptable level.

– If the appliance is installed in an area where the temporary

hardness of the water supply is high, say over 150 ppm,

the fitting of an in line scale inhibitor may be an advantage.

Consult the Local Water Undertaking if in doubt.

– Devices capable of preventing the flow of expansion water:

e.g. non return valves and/or loose-jumpered stop cocks

should not be fitted unless separate arrangements are

made for expansion water.

– For specific information relating to fittings (eg. Showers,

washing machines etc.) suitable for connection in the

D.H.W. circuit, consult the Local Water Undertaking,

however the following information is given for guidance.

2.10.1 Domestic hot/cold water supply

taps and mixing taps

All equipment designed for use at mains water pressure is

suitable.

2.10.2 Showers

Any

WRAS

approved shower suitable for the mains water

pressure available may be used.

A loose or flexible shower head type may require the fitting of

an anti-syphon device to comply wth water by-laws.

2.10.3 Bidets

Providing that the appliance is of the over-rim flushing type,

the outlets are shrouded and it is impossible to attach a

temporary hand held spray, no anti syphonage device is

necessary.

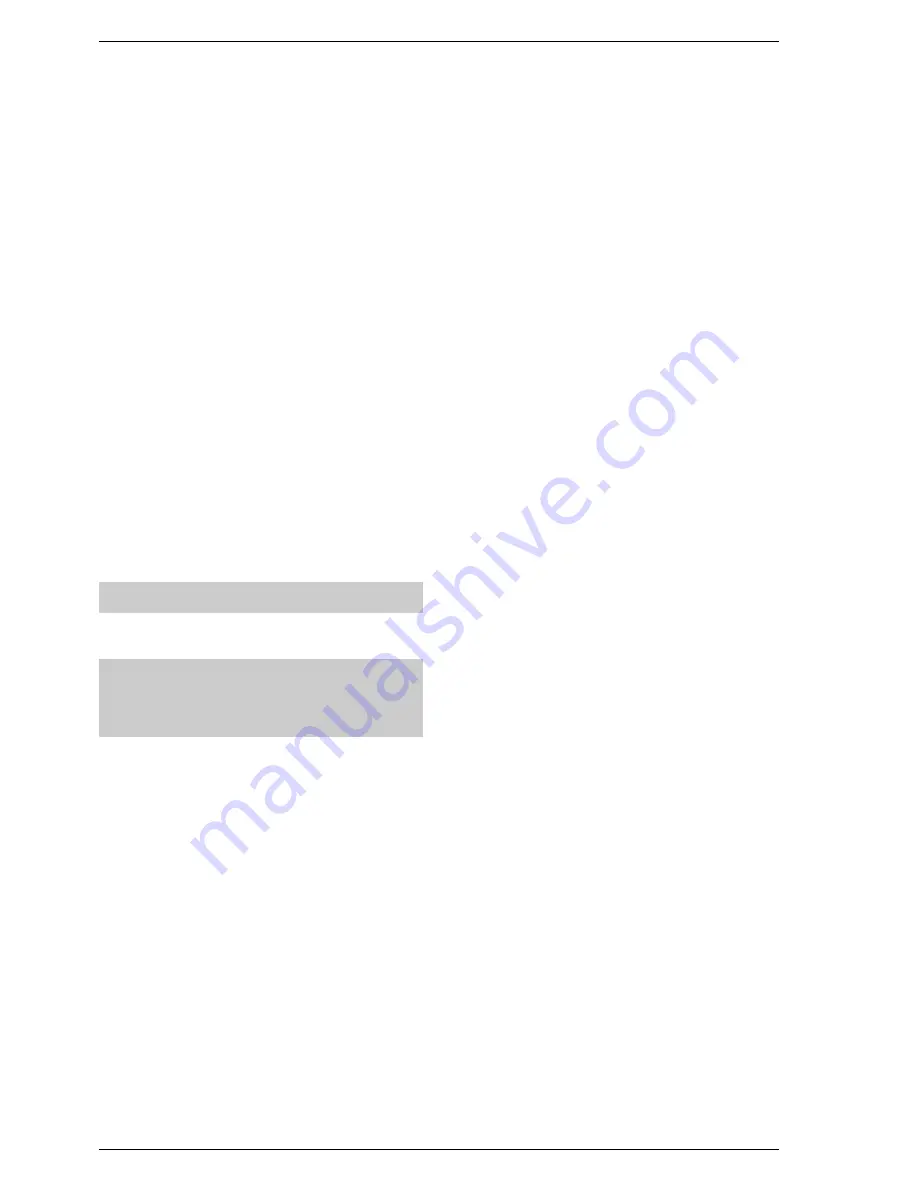

Vessel charge and initial system

pressure

Total water content of system

using 8 l (1.76 gal) capacity expan-

sion vessel supplied with appliance

For systems having a larger capaci-

ty multiply the total system capacity

in litres (gal) by the factor to obtain

the total minimum expansion vessel

capacity required litres (gal)

bar

psi

l

gal

0.5

7.3

96

21.1

.0833

1.5

21.8

51

11.2

.156

1.0

14.5

74

16.2

.109

TABLE 6

Summary of Contents for Format B

Page 3: ......

Page 34: ...COD TYPE DATE PAGE 3820086 318 FORMAT 80B 100B 26 04 2007 1 4 34 9 EXPLODED VIEWS ...

Page 39: ......