61

EN

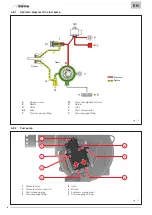

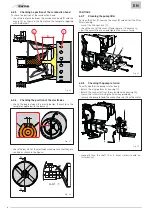

Fig. 51

Replace the pump if remains seized or if it resists manual ro-

tation.

To mount the pump back on:

– apply the joint to the pump shaft (4) and insert it in the motor

housing;

– screw the oil pipe onto the housing (1);

– put the connector back onto the solenoid valve housing (2).

a

WARNING

When the burner starts up, check that there are no

leakages from the pump.

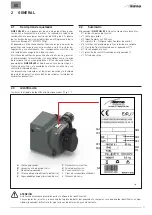

6.2.9

Scheduled replacement of worn components

The table below shows the components subject to wear and

their life cycle, at the end of which they should be replaced

exclusively by the

SIME

Technical Service or by professionally

qualified personnel

Components

Life cycle

(years)

Nozzles

1

Seals

2

Fuel supply pipes

2

Flame monitoring systems

3

Ignition electrodes

2

Power cable

5

Magnesium anode

1

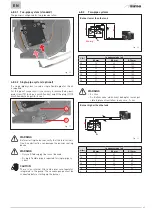

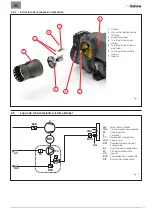

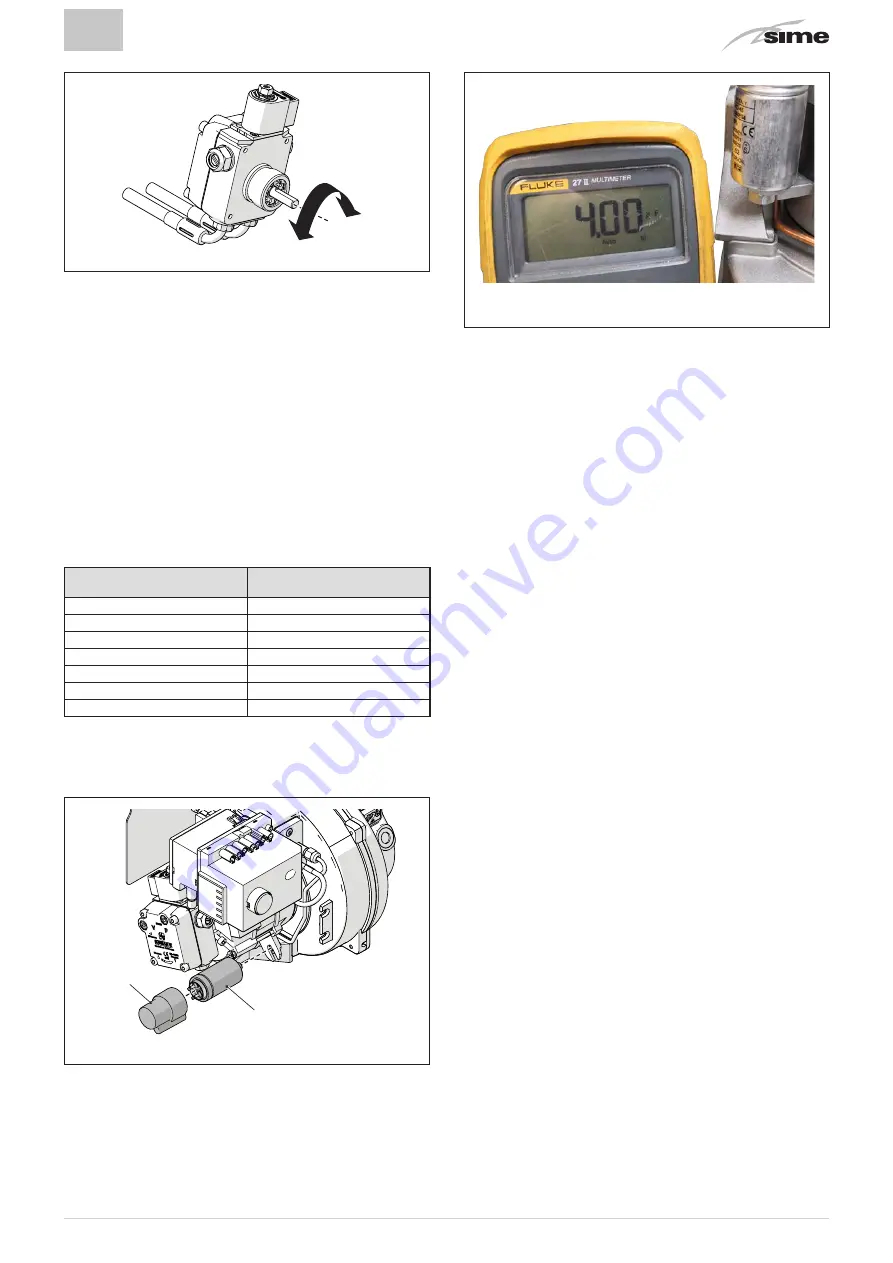

6.2.10 Replacing the capacitor

To replace the capacitor:

– remove the protective cap (1) from the capacitor (2);

1

2

Fig. 52

– disconnect the power supply to the capacitor;

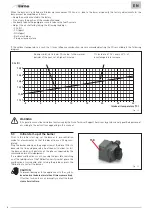

– connect a tester to the Faston terminals of the capacitor; if the

reading is roughly 10% higher than the rated capacity shown

on the capacitor, it means that the capacitor is damaged.

Fig. 53

The value shown in the figure refers to a 4 μF capacitor and is

purely indicative. Please refer to the characteristics of the capa-

citor mounted on the burner.

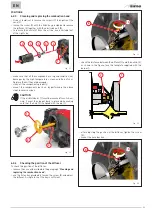

– Remove the capacitor (2) and replace it

– Mount the components back on by performing the above

steps in reverse order.

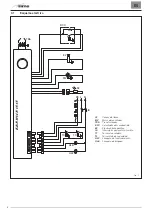

m

CAUTION

– After completing the maintenance operations and

mounting the burner back onto the boiler, the bur-

ner must be started up by performing the procedure

described in the chapter “COMMISSIONING”.