42

EN

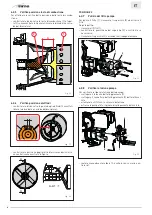

2.6

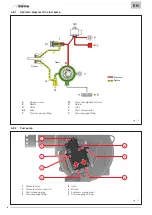

Electrical control and command equipment

The EBR-M14 command and control electrical equipment con-

trols and monitors the burner’s operation. The microprocessor

controls the programme’s sequence and guarantees maximum

stability of the cycle times, regardless of any fluctuations in

the supply lines or of the room temperature. The control unit

is made with materials that guarantee protection against the

potential consequences caused by open flames. Whenever the

supply voltage drops below its minimum rated level (70 ± 8 V),

the control unit locks out, even if no error signal appears. It swi-

tches back on after the supply voltage rises again above (190 ±

8 V).

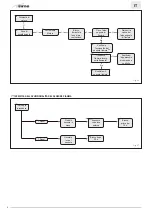

2.6.1

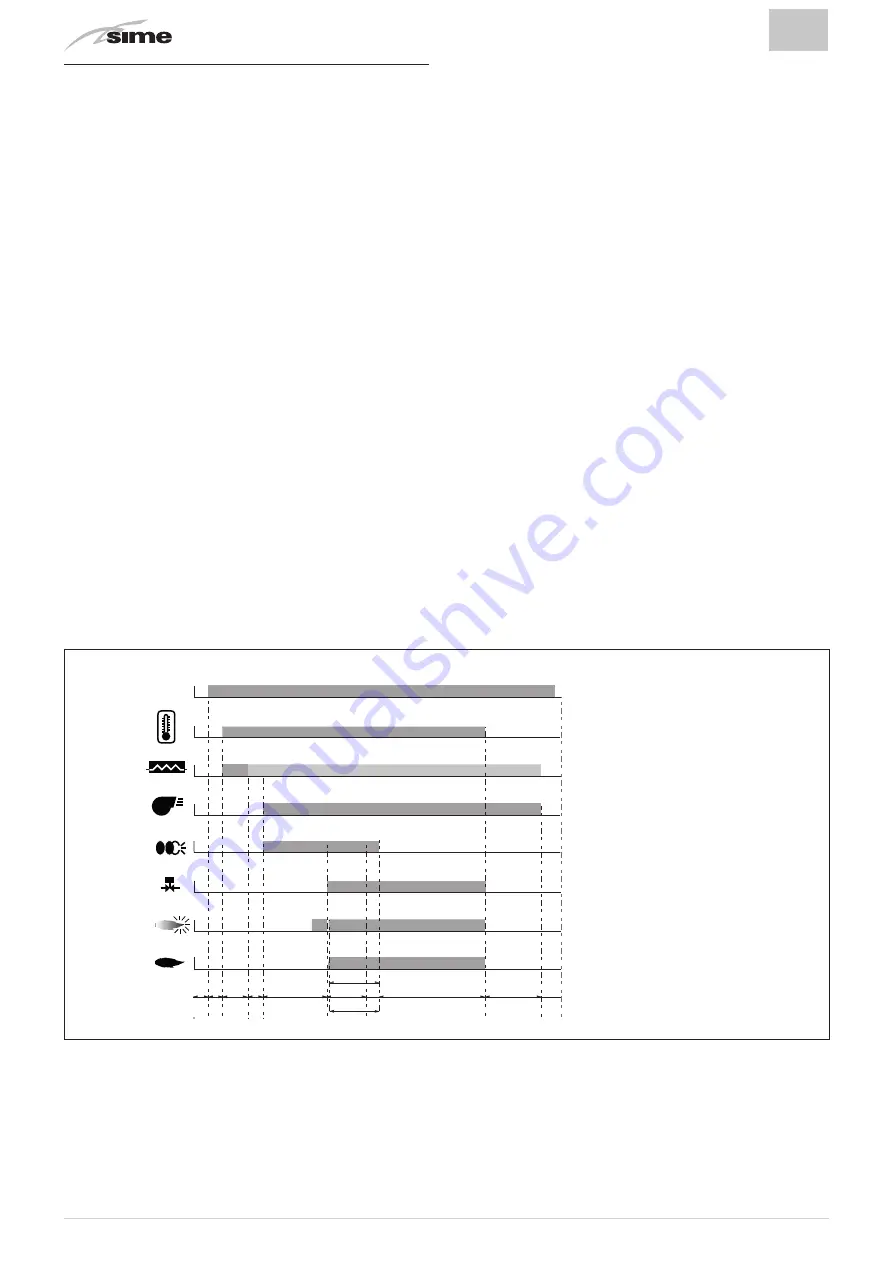

Operating function

– If there is a heat request (green LED lit), the command and

control unit will start the programme’s sequence.

– The heater heats the diesel in the oil line.

– When the optimal temperature is reached, the motor starts,

the ignition transformer activates and the 15-second pre-ven-

tilation phase starts.

– During the pre-ventilation phase, the burner is monitored

through the flame signal.

– Once the pre-ventilation phase terminates, the diesel sole-

noid valve opens, the flame ignites and the burner starts.

– The ignition transformer remains engaged for the entire du-

ration of the post-ignition phase.

2.6.2

Controlled stoppage

Controlled stoppage occurs if:

– the boiler thermostat interrupts the heat request;

– the oil solenoid valve closes and the flame goes out;

– the 15-second (factory-set time) post-ventilation cycle starts,

after which the motor stops;

– the burner enters the stand-by mode pending a new heat re-

quest.

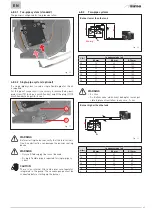

2.6.3

Safety function

A safety shutdown occurs if:

– during the pre-ventilation phase there is a flame signal (flame monitoring);

– the flame has failed to ignite within the safety interval (5s from the opening of the fuel solenoid valve).

A safety shutdown is signalled by the lock-out indicator light (lit steady red).

The operating conditions can only be restored (reset) once the cause of the lock-out has been eliminated and the reset button (9) has

been pressed, as illustrated in “Fig. 2”.

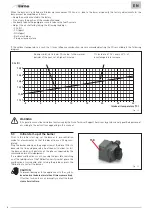

Boiler

temperature

control

General

power

supply

Motor

Ignition

Transformer

Fuel solenoid

valve

Flame check

Flame

Pre heater

-

-

tr

th

to

tp

ts

tpp

tpi

LINE

C

15s

10s

5s

7s

<400s

15s

to

Stand-by: the burner waits for the

heat request

tr

Heating time

th

Stabilisation time

tp

Pre-ventilation time

ts

Safety time

tpi

Post-ignition time

tpp

Post-ventilation time

Fig. 6