51

EN

5 COMMISSIONING

5.1

Preliminary operations

m

CAUTION

The commissioning and initial start-up operations

must be carried out ONLY by professionally qualified

personnel who must follow the indications provided in

this manual and in the manual of the relevant boiler.

The operator must wear personal protective equip-

ment.

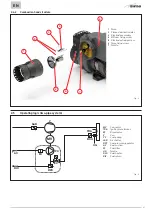

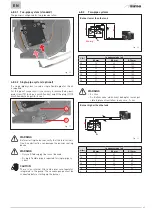

Prior to commissioning the appliance, remove the screws (4)

and (8) and install a vacuum gauge and a pressure gauge re-

spectively.

Then verify that:

– There is sufficient fuel in the tank.

– The fuel, thermal system and water circuit valves are open.

– The electrical connections have been made correctly.

– The exhaust pipes for combustion by-products have been ar-

ranged correctly.

– In case of TYPE B installations, the vents are adequately sized

in relation to the installed power and the combustion air inlet

of the burner is free (without splits).

– The fume exhaust system has been made correctly.

– The system has been correctly pressurised and all the expan-

sion vessels have been pre-charged.

– The control, command and safety devices are present.

4

8

Fig. 27

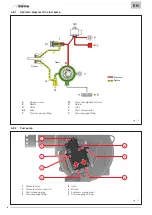

5.2

Factory calibration

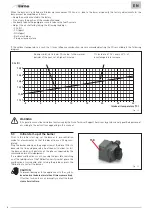

All the burners are adjusted and tested in the factory according to the data shown in the table and in the reference conditions specified

below.

Burner

Burned power

+/- 4%

Nozzle

(Danfoss)

Pump pres-

sure*

Air shutter adjustment

Model

kW

Kg/h

GPH

Spray

bar

mm (+/-0,1)

SIME FUEL 25 EV (vers. std)

27

2,28

0,55

60°H

12,0

3,8 +/- 0,2

SIME FUEL 35 EV (vers. std)

35

2,90

0,65

60°H

12,0

5,7 +/- 0,2

SIME FUEL 25 EV (vers. HE)

27

2,28

0,55

60°H

12,0

3,5 +/- 0,2

SIME FUEL 35 EV (vers. HE)

35

2,90

0,65

60°H

12,0

5,5 +/- 0,2

(*) The pump pressure is measured after an operating interval of 5 min.

Reference conditions

– Fume exhaust system: diameter 80 mm / length 1.5 m

– Room temperature: 20°C +/-5

– CO

2

= 12,5% ± 0,2.

– Altitude 0 m.a.s.l..