65

EN

8 APPENDIX

8.1

Use of biodiesel

The burner is suitable for working with a biodiesel blend of up

to 10%. This is a minimum requirement in conformity to the ap-

plicable standards, the regional regulations and FAME require-

ments in conformity to EN 14214.

m

CAUTION

If the burner must be used with fuels containing bio-

fuel percentages above 10%, contact the manufactu-

rer.

8.2

Important suggestions for using biofuel

blends

8.2.1

Introduction

The growing attention towards renewable and sustainable ener-

gy foreshadows an increasingly widespread use of biofuels.

If you plan to use them, a few technical aspects must be taken

into account for reducing potential faults in the burner and in

the system, besides the risk of fuel leakages.

“Liquid biofuel” is a broad term that identifies oil deriving from

numerous raw materials, including recycled cooking oil. These

types of oil must be considered and treated differently to com-

mon mineral and fossil fuels, since they are more acidic, hygro-

scopic and less stable.

Special care must be taken when storing the fuel, in the con-

veying piping, in the ancillary equipment, during filtration and in

the choice of the burner.

The classification of biofuel is important for the efficient opera-

tion of the equipment.

m

CAUTION

The owner or the manager of the plant is responsible

for thoroughly analysing the potential risks associated

with the introduction of a biofuel blend, the suitability

of the appliances and the installation.

8.2.2

General information and instructions

The fuel supplier must demonstrate conformity to an accredited

quality management system for its own storage, mixing and de-

livery processes.

In the installations, make sure that all the materials and sealing

devices of the storage tank and of the pipe conveying the oil to

the burner are compatible with biofuels.

The tank must include a high-quality biocompatible oil filter

plus a size 60 micron secondary filter for protecting the burner

against contaminations.

Whenever an existing tank must be used to store the oil, in ad-

dition to the above-mentioned checks on the materials, it is

essential that the tank be inspected above all to verify its con-

ditions and to make sure that it does not contain water or other

contaminants. If contaminants are found, deep cleaning must

be performed. If this is not done, the hygroscopic nature of the

fuel could cause complex components to dissolve and to detach

causing the appliance to malfunction.

Depending on the storage tank’s capacity and on how the plant

is used, fuels can remain inside it for a considerable period of

time. Consult the biofuel distributor for information on how to

use biocides to prevent microbial growth inside the tank and for

instructions on fuel filtering.

When commissioning the burner, check that all the combustion

parameters conform to the recommended values appearing in

the appliance’s technical manual.

Check the filters of the pipe and of the burner’s oil pump and

replace them if necessary:

– At least every 4 months during burner use

– Prior to starting the burner following a prolonged shutdown

– More frequently in case of contamination.

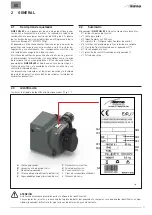

a

WARNING

Be particularly careful during checks and inspections

for detecting fuel leakages from sealing devices, seals

and flexible pipes.

a

WARNING

If a biofuel blend is used, consult the biofuel distri-

butor.