“

∆

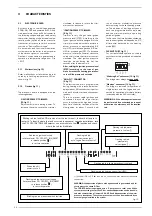

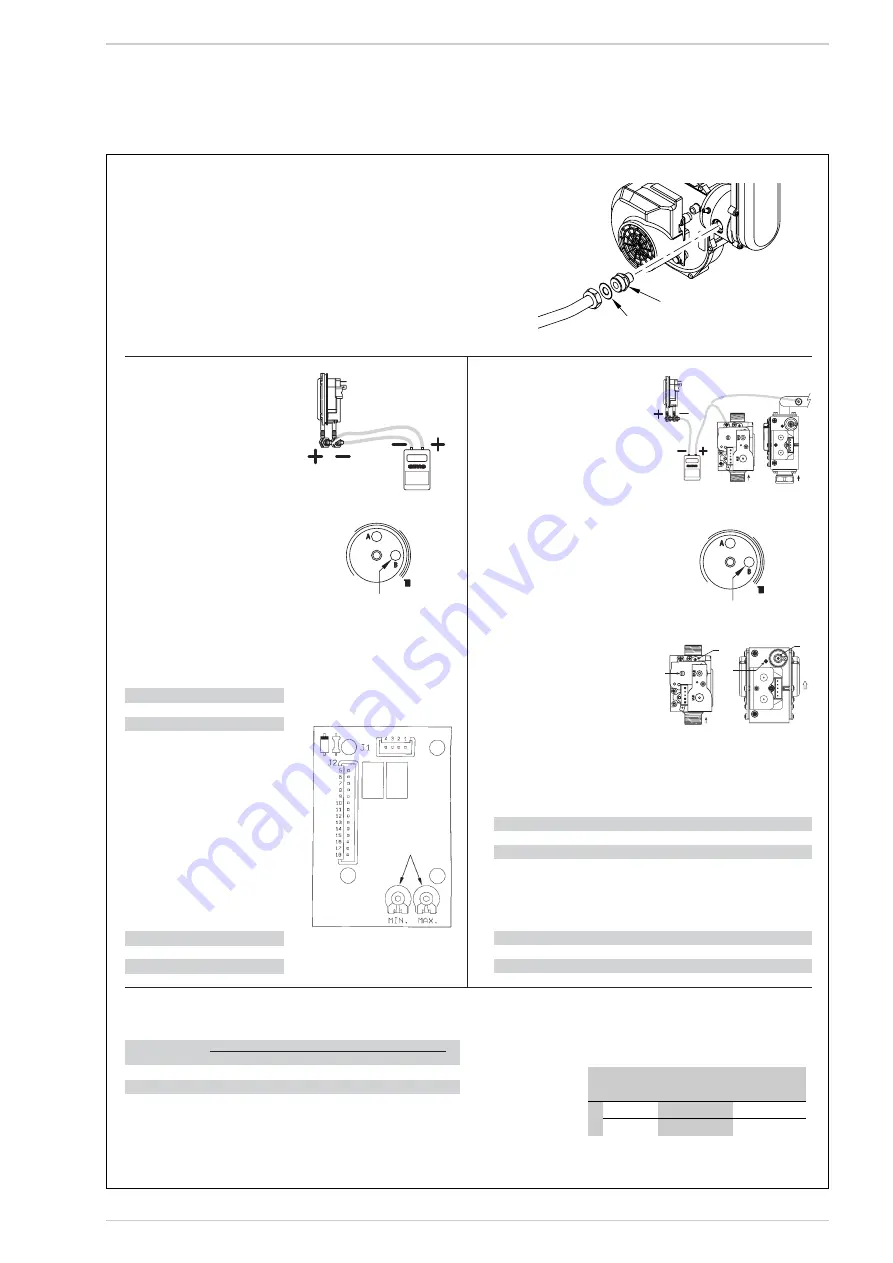

p air” ADJUSTMENT

To measure “

∆

p air” simply con-

nect the differential pressure

gauge, equipped with a decimal

scale in mm H

2

O or Pascal, to the

positive and negative sockets on

the air pressure switch

(Drawing

1).

Operating sequence:

1)

Rotate the module heating

power adjustment trimmer

clockwise to the limit

(B –

Drawing 2); fan on maximum.

2)

Find the “max

∆

p air” values in

the table, using the fan board

“MAX” trimmer

(Drawing 3):

Max.

∆

p air (mm H

2

O)

3)

Rotate the module heating

power adjustment trimmer

counter-clockwise to the limit

(B

– Drawing 2); fan on minimum.

4)

Find the “min

∆

p air” values in

the table, using the fan board

“MIN” trimmer

(Drawing 3):

Min.

∆

p air (mm H

2

O)

“

∆

p air-gas” ADJUSTMENT

To measure “

∆

p air-gas” simply

connect the positive socket on

the differential pressure gauge to

the downstream pressure fixture

and the negative socket to the air

pressure switch

(Drawing 4).

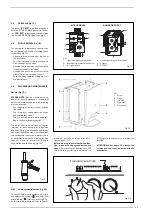

Gas pressure is always adjusted

with the fan on minimum.

Operating sequence:

1)

Rotate the module heating

power adjustment trimmer

counter-clockwise to the

limit

(B – Drawing 5); fan on

minimum.

2)

Completely unscrew the valve

gas shutter

(1 – Drawing 6).

Single modules are calibrated in heating position.

Pressostato aria

60 kW

100 kW

1

2

60 kW

100 kW

2

1

After calibrations, check the CO

2

values with a combustion analyser. If they deviate more than 0.2 from the table values, the following corrections

must be made:

– To correct CO

2

to the “MIN” power, use the OFF-SET screw

(2 – Drawing 6).

– To correct CO

2

to the “MAX” power, use the shutter

(1 – Drawing 6).

Drawing 6

Single module

60 kW 100 kW

G20

60.0 ±2 65.0 ±2

G31

63.0 ±2 70.0 ±2

Single module 60 kW

100 kW

G20

5.8 ±0,2

6.5 ±0,2

G31

10.9 ±0,2 7.0 ±0,2

B

Drawing 5

3)

Use the gas valve OFF-SET adjustment screw

(2 – Drawing 6) and

find the “

∆

p air-gas” value in the table.

Shutter open (mm H

2

O)

4)

Use the shutter

(1 – Drawing 6) and find the “

∆

p air-gas” value in

the table:

Adjusted shutter (mm H

2

O)

Single module

60 kW

100 kW

G20

4.2 ±0,1

5.2 ±0,1

G31

9.2 ±0,1

6.5 ±0,1

Single module

60 kW

100 kW

G20

3.8 ±0,1

4.3 ±0,1

G31

8.7 ±0,1

4.6 ±0,1

CO

2

Methane (G20)

Propane (G31)

“MIN” Power

9.0 ±0,2

10.0 ±0,2

“MAX” Power

9.0 ±0,2

10.0 ±0,2

Pressostato aria

B

Drawing 2

Drawing 1

Air pressure switch

Drawing 3

Air pressure switch

Drawing 4

“

∆

p air”

min/max

adjustment

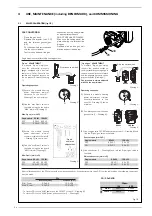

GAS CONVERSION

– Close the gas cock.

– Replace the injector (pos. 30)

and the relevant gasket (pos.

45).

– Cut the specified resistance on

the fan control board.

– Test for soundness all the gas

connections using soapy water

or appropriate products.

DO NOT USE NAKED FLAMES.

– Stick onto the casing panel the

plate showing the relevant fee-

ding gas.

– Proceed with air and gas cali-

bration as described below.

30

45

GB - 04/08

4.1

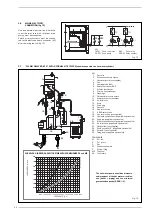

BOILER CALIBRATION (fig. 16)

Fig. 16

24

4

USE, MAINTENANCE (including BENCHMARK), and COMMISSIONING

CO ppm

100

400

CO

2

%

NG 9%

0,0011

0,0044

LPG 10%

0,0010

0,0040

CO / CO

2

RATIO

Summary of Contents for Planet Dewy 100 BFR

Page 3: ......

Page 29: ...29 For 100 BFR and boilers in cascade ...

Page 30: ...30 ...

Page 32: ...32 5 EXPLODED VIEWS COD TYPE DATE PAGE 3830005 345 PLANET DEWY 60 BFR UK 20 01 2010 1 4 ...

Page 33: ...33 COD TYPE DATE PAGE 3830005 345 PLANET DEWY 60 BFR UK 20 01 2010 2 4 ...

Page 36: ...36 COD TYPE DATE PAGE 3830037 212 Planet Dewy 100 BFR UK 20 01 2010 1 4 ...

Page 37: ...37 COD TYPE DATE PAGE 3830037 212 Planet Dewy 100 BFR UK 20 01 2010 2 4 ...