94

3.3

ELECTRONIC

IGNITION

Ignition and flame detection is controlled

by two electrodes located on the burner.

These guarantee maximum safety with

intervention times, for accidental swit-

ching off or gas failure, of within one

second.

3.3.1

Operating cycle

Rotate the selector knob to summer or win-

ter, and verify that green led (

) lights up to

confirm the presence of voltage.

The burner must be ignited within 10

seconds. However, it is possible for ignition

failures to occur, with consequent activa-

tion of signal indicating that the control box

has “locked out”.

–

Gas failure

The electrode continues spark discharge

for a maximum of 10 sec.If the burner

does not light, the lock-out indicator will

light up.

This may occur upon first ignition or

after long periods of boiler lay-off when

there is air in the pipes. It may be caused

by the gas cock being closed or by one of

the valve coils having a break in the win-

ding, so that the valve cannot open.

–

Ignition electrode fails to spark

In the boiler, only the gas to the burner

is seen to open.

After 10 sec. the warning light indica-

ting equipment “lock-out” lights up.

This may be due to a break in the wire of

the electrode or to the wire not properly

fastened to the electric terminal of the

control box or the ignition transformer.

–

No detection of flame

The continuous spark discharge of the

electrode is noted starting from ignition

even though the burner is lit.

A f t e r 10 s e c o n d s h a v e e l a p s e d , t h e

sparks cease, the burner goes out, and

the warning light indicating equipment

“lock-out” lights up.

There could have a break in the wire of

the sensing electrode or the electrode

itself is touching earth: the electrode is

worn out and needs replacing. The con-

trol box is defective.

When there is a sudden voltage failure, the

burner shuts out immediately; when power

supply returns, the boiler will start up again

automatically.

3.4

AIR PRESSURE

SWITCH

The air pressure switch is factory set to

the values 40-57 Pa to guarantee boiler

functioning even with intake and flue pipes

at the maximum permitted length.

The value of the signal to the pressure

switch is measured using a special instru-

ment connected to the pressure intake

(5-4 fig. 3).

3.5

FLOW SWITCH SAFETY VALVE

A flow switch safety valve (18 fig. 3) interve-

nes, blocking the operation of the burner if

the boiler is without water due to the for-

mation of an air lock in the heat exchanger

or if the circulator is not working, or becau-

se the “Aqua Guard” filter is obstructed with

impurities.

NOTE: If replacing the flow switch valve,

make sure that the arrow stamped on

the valve points in the same direction as

the flow of water.

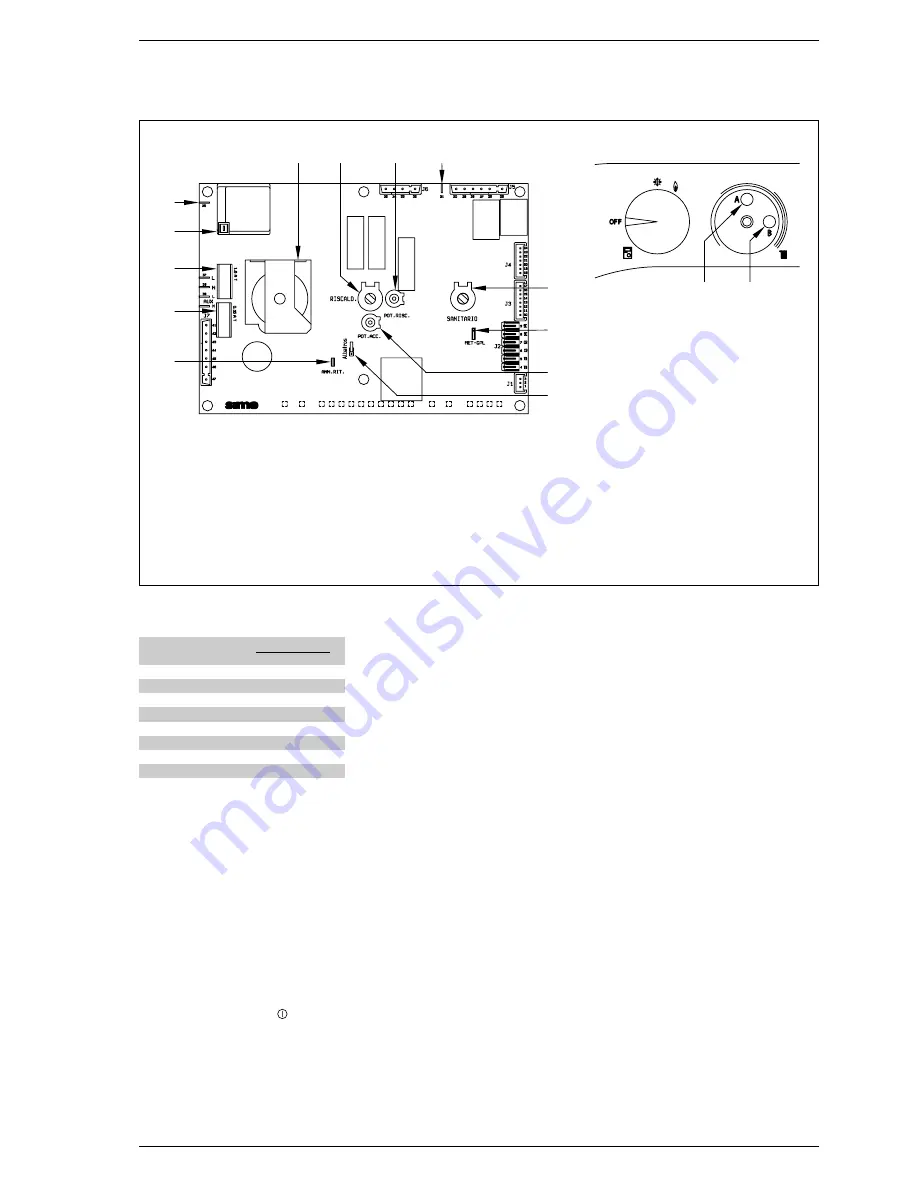

Fig. 20

1

2

3

4

5

12

11

10

9

8

7

6

15

6

10

KEY

1 Ignition electrode earth faston

2 Ignition electrode faston

3 Fuse (1,6 AT)

4 Fuse(0,16 AT)

5 “ANN. RIT.” connector

6 “POT. ACC.” trimmer

7 Conector “MET-GPL”

8 ------

9 Detector electrode faston

10 “POT. RISC.” trimmer

11 C.H. potentiometer

12 Selector CR/OFF/EST/INV/RESET

15 Albatros RVA 47 conector

NOTE:

To gain access to trimmers (6) and (10), unscrew

the central heating potentiometer knob.

TABLE 3/a (Transducer)

Pressure

Resistance (

Ω

)

(bar)

min

max

0

297

320

0,5

260

269

1

222

228

1,5

195

200

2

167

173

2,5

137

143

3

108

113

3,5

90

94

WARNING: In sequence/cascade

installations, turn trimmer B (10) as

far as it will go clockwise.