43

4.1

GAS VALVE

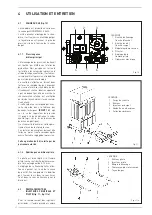

(fig..10)

“RMG P”

boilers.come.equipped.stan-

dard.with.a.HONEYWELL.VR.4400.gas.

valve..

When. the. boiler. is. ignited. the. first.

time,. it. is. always. recommended. to.

bleed.the.piping.by.using.the.pressure.

outlet.upstream.from.the.valve.

4.1.1 Gas pressure

on the main burner

The. pressure. is. adjusted. by. SIME. in.

the. production. line.. But. since. in. the.

place.of.installation.the.pressure.sup-

ply. values. can. change,. it. is. required.

to.verify.gas.pressure.and.flow.at.the.

first.ignition.

The. check. is. carried. out. by. reading.

twice.the.gas.meter,.with.a.six.minute.

interval,. and. with. the. boiler. conti-

nuously.operating.while.all.other.gas.

appliances

must.be.switched.off.

The. reported. consumption. must. be.

multiplied. by. ten. so. as. to. calculate.

the. hourly. consumption.. If. this. value.

does. not. match. the. one. listed. in. the.

technical.data.table.

(POINT 1.3)

,.turn.

the. screw. of. the. pressure. regulator.

(3). until. you. have. obtained. the. exact.

value.(turn.the

screw.below.the.plastic.cap).

We.recommend.that.you.perform.this.

operation. in. a. slow. and. gradual. way..

The. readings. on. the. meter. must. be.

made.at.least.thirty.seconds.after.you.

performed.the.pressure.adjustment.

This operation must always be per-

formed by authorized personnel.

4.1.2 Gas flow to the pilot burner

The. pilot. is. correctly. adjusted. if. the.

pilot. flame. covers. the. end. of. the.

thermocouple. for. a. 8-10. mm. length..

Adjustment.of.the.pilot.flame.is.made.

by.acting.on.the.screw.of.the.gas.valve.

(5).. To. increase. the. gas. flow,. turn.

the. screw. clockwise,. turn. it. counter-

clockwise.to.decrease.it.

4.3

MAIN AND PILOT

NOZZLES REPLACEMENT

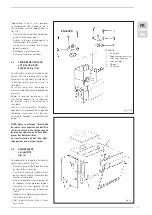

(fig. 11 - fig. 11/a)

To. replace. the. main. nozzles. proceed.

as.described.in.fig..11,.to.change.the.

pilot.nozzle.instead.proceed.as.descri-

bed.in.fig..11/a:

-..Loosen. the. screws. that. secure. the.

4 USE AND MAINTENANCE

Fig..11/a

KEY

. 1. Pilot.burner

. 2. Pilot.nozzle

. 3. Spark.plug

. 4. Interrupted.thermocouple

. 5. Gas.pipe

1

2

3

4

5

6

Fig..10

KEY

. 1. Ignition.button

. . (white.button)

. 2. Shutdown.button

. . (red.button)

. 3. Pressure.regulator

. 4. Coil.assembly

. 5. Pilot.flame.adjustment

. 6. Terminal.board

Fig..11

KEY

. 1. Boiler.body

. 2. Burner

. 3. Main.nozzle

. 4. Aluminium.washer

. 5. Burner.manifold

Summary of Contents for RMG 100 P

Page 1: ...Fran ais English RMG 70 110 P Cod 6100019 11 2016...

Page 2: ...1 2 3 4...

Page 3: ...1 RMG P G20 G25 G30 G31 1 2...

Page 5: ...2 1 RMG P 35 412 93 7131 72 7129 922 6 100 37 55 12 04 96 74 3 4 1 2 3000 2 2 1...

Page 6: ...2 3 2 3 1...

Page 7: ...2 4 1 2 5 500 20...

Page 8: ...2 5 1 4 7129 92 35 2 6 230 50 3 60730...

Page 9: ...2 6 1 IG TC EV TA TS TF T TA 3 4...

Page 10: ...2 7 MAX MAX 80 60 MAX 50 30 MAX MAX MIN MIN 80 60 MIN 50 30 MAX MIN MAX GAS UK WRAS UK...

Page 11: ...3 7...

Page 12: ...3 2 8 4 4 1 10 V 4400 Di re 1 2 3 4 5 6...

Page 13: ...4 1 1 SIME POINT 1 3 3...

Page 14: ...4 1 2 8 10 5 1 2 3 4 5 11 11 1 2 3 4 5 6...

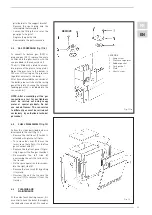

Page 15: ...4 4 11 G30 G31 300 H2O 4 5 12 12 1 3 2 4 5 6...

Page 16: ...7 4 6...

Page 17: ...4 7...

Page 18: ...6 7...

Page 19: ......

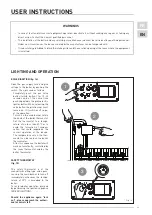

Page 20: ...14 15 20 60...

Page 21: ...15 95...

Page 22: ...16 OFF...

Page 23: ......

Page 48: ...48 FR EN NOTE...

Page 49: ...49 NOTE...

Page 50: ......

Page 51: ......