Installation / Operation

4

For parts or assistance, call Simer Customer Service at

1-800-468-7867 / 1-800-546-7867

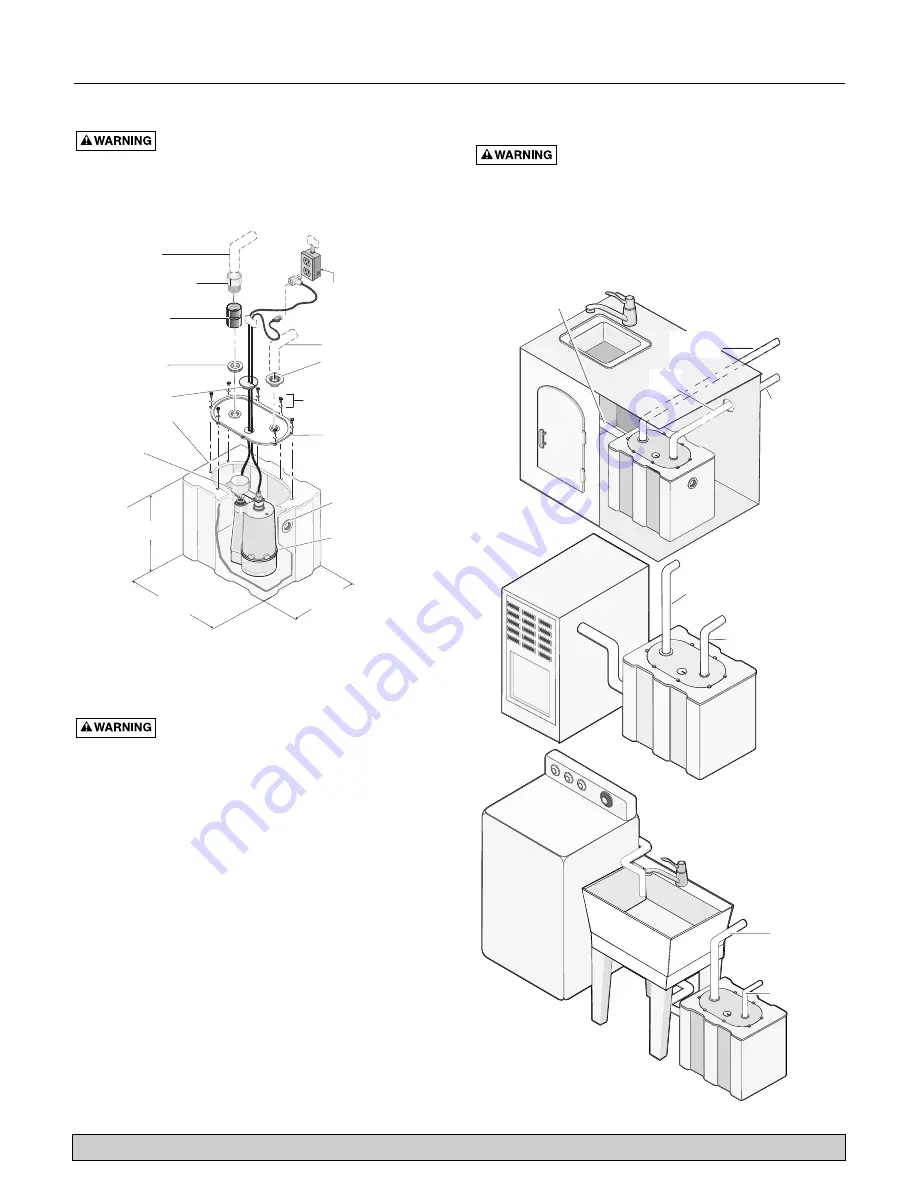

The Laundry Pump System (See Figure 1)

Risk of Flooding. Flooding may cause per-

sonal injury or property damage.

Flooding will occur if a

washing machine discharges directly into the basin. A

washer must discharge into the sink and the sink drain

must run into the basin. The sink drain must be gravity fed.

OPERATION

Risk of electric shock. Shock can burn or

kill.

Do not handle a pump or pump motor with wet

hands or when standing on wet or damp surface, or in

water.

1. Keep the pump inlet screen clear.

2. The shaft seal depends on water for lubrication. Do

not operate the pump unless it is submerged in water

as the seal may be damaged if the pump is allowed

to run dry.

3. The motor is equipped with an automatic reset ther-

mal protector. If the temperature in the motor should

rise unduly, the switch will cut off all of the power

before any damage can be done to the motor. When

the motor has cooled sufficiently, the switch will reset

automatically and restart the motor. If the protector

trips repeatedly, the pump should be removed and

checked for the cause of the difficulty. Low voltage,

long extension cords, a clogged impeller, very low

head or lift, etc., could cause cycling. Refer to the

Troubleshooting Chart on Page 6 for additional infor-

mation.

4. Periodically inspect the pump, system components

and basin for debris and foreign objects. Keep the

basin free of all refuse. Perform routine maintenance

as required.

Risk of flooding. Flooding can cause per-

sonal injury or property damage.

This laundry pump sys-

tem comes with the automatic float switch mounted on

the motor cover ready for operation. Do not change

switch settings. The switch is set to start when the water

is 7” deep and stop when the water is 2” deep.

Discharge

Pipe

Vent

Pipe

Drain Pipe

from Wet

Bar Sink

Vent to Sewer

Vent System

Discharge

Pipe

Vent

Pipe

Vent

Pipe

Discharge

Pipe

Figure 2 – Typical uses.

Cord grommet

Capscrews and

Washers (8 of each)

2" Uniflex

Vent Fitting

(Grommet)

Vent Pipe

Discharge

pipe

1-1/4" or 1-1/2"

Uniflex Fitting

(Grommet)

Customer Supplied

Adapter 1 1/4 x slip

14"

(355.6mm)

17"

(431.8mm)

11.75"

(299mm)

2427 0596 SIM

Basin Cover

1-1/2" Inlet

Fitting

Submersible

Sump

Pump

Vertical

Float

Switch

10-Gallon water

basin with cover

Plug into a

3-wire grounded,

grounding-type

receptacle only.

Check Valve

(Grommet)

Figure 1 – Laundry Pump System Installation Diagram.