Pi ping – Effluent Applications

(3/4” or Less Solids)

Piping must be 1-1/2” minimum to carry

volume of pump discharge. Check local codes

to determine if a check valve is required in your

system. In cold climates, check valves are not

used to prevent effluent from freezing in piping.

Piping – Sewage Applications (2” or Less Solids)

In all cases, piping must not be smaller than

pump discharge.

When installed in a sewage system, pipe must

be capable of handling semi-solids of at least

2” (5.1 cm) diameter.

The rate of flow in the discharge pipe must keep

any solids present in suspension in the fluid.

To meet minimum flow requirements (2 feet

(61 cm) per second in discharge line), size pipe

as follows:

A Pipe Size of:

Will Handle a Flow

Rate of:

1-1/2” (3.8 cm)

12 GPM (45 LPM)

2” (5.1 cm)

21 GPM (79 LPM)

2-1/2” (6.3 cm)

30 GPM (113 LPM)

3” (7.6 cm)

48 GPM (181 LPM)

NOTICE Use PTFE pipe thread sealant tape on

pipe connections. Do not use ordinary pipe joint

compound on plastic pipe or pump. Pipe joint

compound can attack plastics and damage pump.

3. To reduce motor noise and vibrations, a short

length of rubber hose can be connected

into discharge line near pump using

suitable clamps.

4. If the pump discharge line is exposed to

outside subfreezing atmosphere, then the

portion of line exposed must be installed so

any water remaining in pipe will drain to

outfall by gravity. Failure to do this can cause

water trapped in discharge to freeze which

could result in damage to pump.

5. Install a 2” check valve in the horizontal

portion of the discharge pipe. Make certain,

the flow indicating arrow, points away from

the pump. This check valve will keep the water

from either running back into the basin or into

the area being pumped out when the pump is

not running. Check valve should be a free flow

valve that will easily pass solids.

Installation 3

For parts or assistance, call Simer Customer Service at 800-468-7867

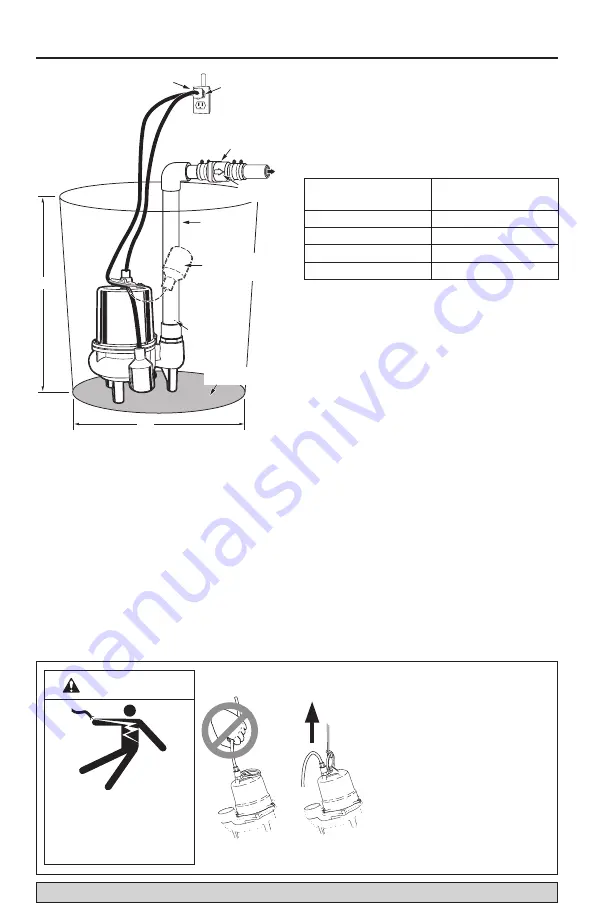

Figure 1 – Typical Installation

Not

to

Scale

2” Check Valve

Mount Horizontally!

Direction

of Flow

2” Discharge

Pipe

18”

30”

Plug Switch into

115V, 3-Prong,

Grounded Outlet

Plug Pump into

Switch Plug

Sewage

Basin

Drill 3/16” Vent

Hole Here

Install the Pump on a

Hard, Level Surface

Float Switch must

Swing Through

Its Entire Arc

6164 0310

1. Attempting to lift or support pump

by power cord can damage cord and

cord connections.

2. Cord may pull apart, exposing bare

wires with possibility of fire or

electrical shock.

3. Lifting or supporting pump by power

cord will void warranty.

4. Use lifting ring or handle on top

of pump for all lifting/lowering of

pump. Disconnect power to pump

before doing any work on pump

or attempting to remove pump

from sump.

WARNING

Risk of electrical shock.

Can burn or kill.

Do not lift pump by

power cord.

Cord Lift Warning