BA_PA-KL²-x-xx_EN_10

www.simon-protec.com

Date: 09.06.2020

Issue: 1.0 / 06.2020

info@simon-protec.com

Page 3

Mounting

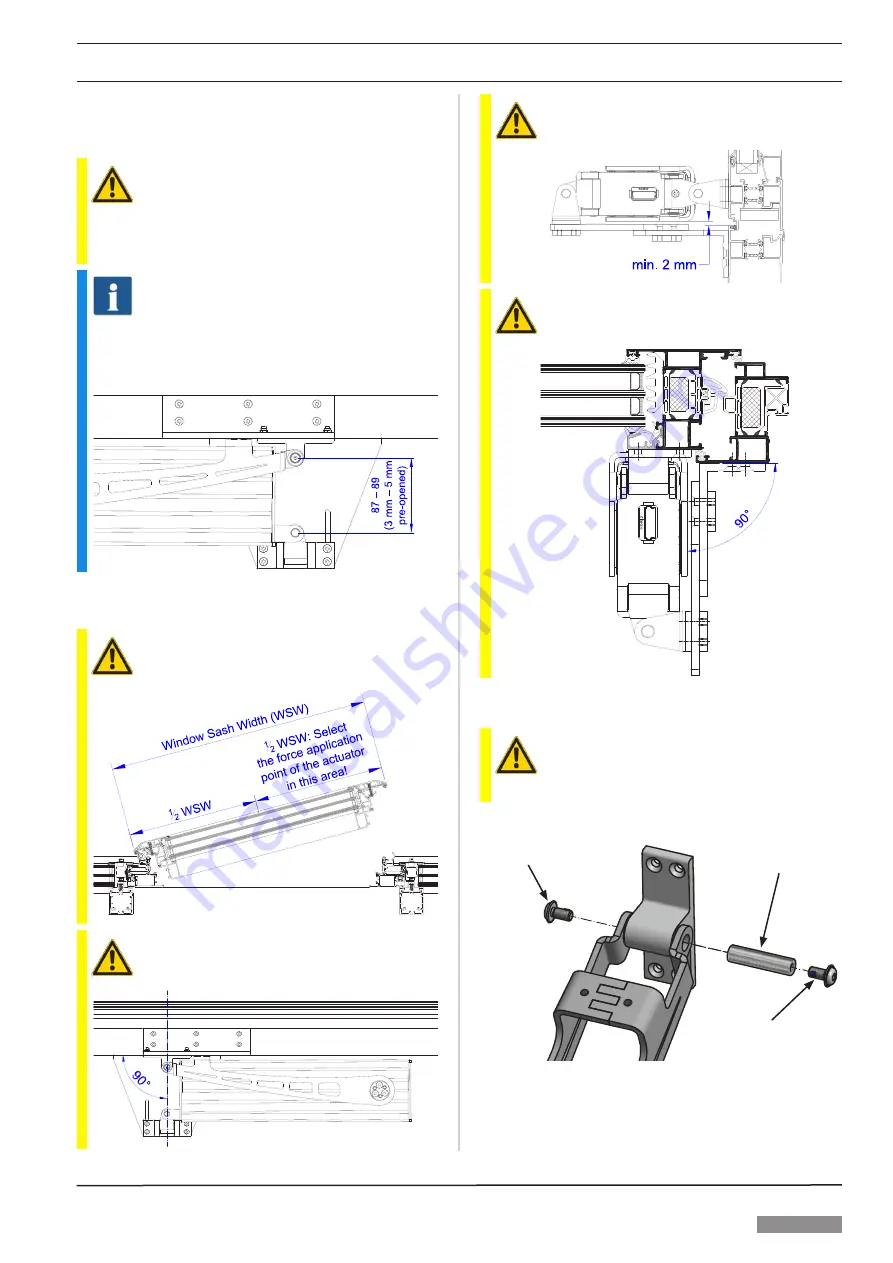

1. Mounting

1.1. Mechanical connection

ATTENTION

All dimensions given in this chapter are minimum specifi

-

cations and may vary depending on the type and design

of the window.

INFORMATION

To guarantee that the window closes tightly, you

should always mount the Folding Arm² actuators slightly

pre-opened (approx. 3 mm – 5 mm) so that the actuators

switch off in the end position of the window:

1.1.1. Folding Arm² position at the window

ATTENTION – force application point

ATTENTION – alignment of the brackets

ATTENTION – distance to the frame

ATTENTION – secondary closing edge

(without cardanic bracket)

1.1.2. Mount the hinged bracket

ATTENTION

Use only the supplied screws with screw locking!

Figure 6

SIMON RWA

Systeme GmbH

Medienstr. 8

94036 Passau

Tel. +49 851 98870-0

Fax. +49 851 98870-70

Blatt:

Revision:

Bezeichnung:

Teile-/Artikelnummer:

Zeichnungsnummer:

Allg. Toleranz:

Oberfläche:

DIN ISO 1302

DIN ISO 2768 - m

Projekt:

Material:

gezeichnet:

Begeisterung trifft Technik

SIMON RWA

R

M.Schwinge

EA-KL2

ET - Klapparm

KL2-1.1-01-4a

2 / 5

0.2

ARM + Konsole

05.05.2010

geprüft / geändert:

von:

am:

22.10.2012

mschwinge

am:

von:

konstruiert:

1,36 kg

Gewicht:

Maßstab:

Blattgröße:

A4

flange head screw

M5 x 16

bracket shaft

flange head screw

M5 x 16

5 Nm

5 Nm