Mounting

BA_PA-KL²-x-xx_EN_10

www.simon-protec.com

Date: 09.06.2020

info@simon-protec.com

Issue: 1.0 / 06.2020

Page 6

1.3. Setting options

You can set

single operation

or

synchronous operation

mode MASTER / SLAVE

via SICO LINK or manually (see

chapter 1.4.1)

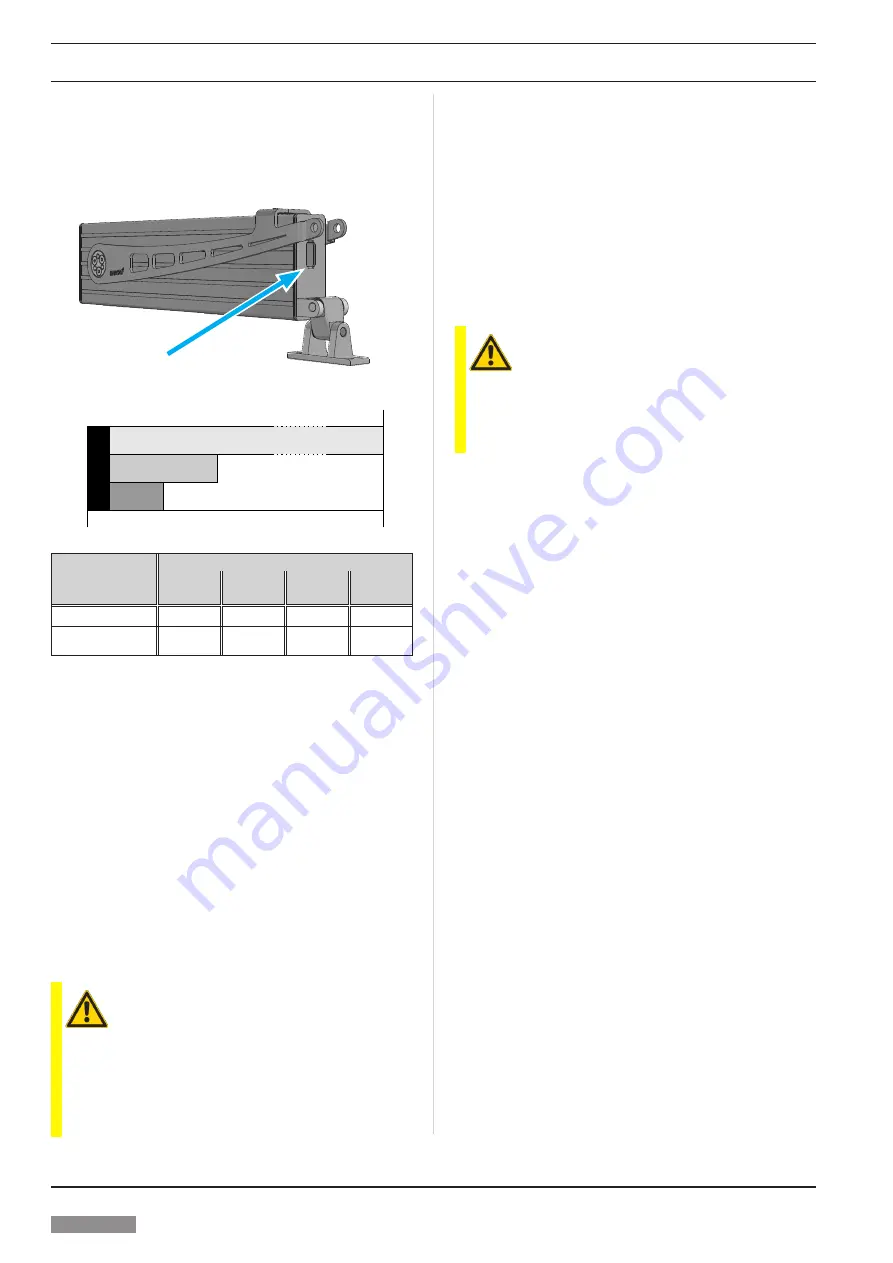

Figure 1: Interface for SICO LINK

Connection for SICO-USB-110

Figure 2: Stroke behaviour

mechanical “0”

electrical “0”

RESET-

range

electronical stroke

span

synchronous operation

stopping range

Actuator type

Folding Arm²

530

710

960

1200

PA-KL²-K

PA-KL²

PA-KL²-M PA-KL²-L

RESET-range

16 mm

21 mm

27 mm

34 mm

Synchronous operat.

stopping range

32 mm

42 mm

54 mm

68 mm

RESET-range

: When the actuator is cut off on overload

within the RESET-range, the electronic zero point will

be set new.

Synchronous operation stopping range

: If an actuator

cuts off in synchronous operation in direction CLOSE

within the

stopping range

, the remaining actuators

continue to run to the zero point until overload cut-off.

1.3.1. Synchronous actuators

The synchronous actuators of the PA-KL² series are identi

-

fied by the suffix “S” in the part number (e.g. PA-KL²-50/710-S

– M2 2001 S).

1.3.2. Zero point

/

RESET-range

It‘s necessary to reset the zero point, if the closed position

of the actuator is out of the RESET-range after installation.

(SICO LINK / RESET-run).

ATTENTION – Span

If the zero point is shifted due to a large pre-opening

(1)

, the

maximum span must not be exceeded.

span = pre-o max. stroke

(1)

Large pre-opening: Outside the permissible parameters. – Permissible pa-

rameters see 1.1.

1.3.3. Operating modes synchronous actuator

If a synchronous actuator is to be used as a single actuator,

the operating mode must be set to “Single operation”

(SICO LINK or RESET-run) – factory setting.

If several actuators are to be used in synchronous operation,

one actuator must be set to “Synchro Master” and the

re

maining actuators to “Slave” (SICO LINK or manual

MASTER

/

SLAVE setting).

1.4. Manual setting

1.4.1. MASTER / SLAVE setting

ATTENTION

Manual setting is only possible for two actuators connected

in parallel (one MASTER and one SLAVE).

For larger groups of actuators (more than one SLAVE),

a setup via SICO LINK is necessary.

¾

Drive the actuator in direction “CLOSE” (

S

= “

–

”

O

= “

+

”)

and let it cut off in the end position. If the actuator does

not reach the „mechanical ZERO“ position due to its

mounting position, a RESET-run must be performed.

¾

Leave the actuator energized!

¾

Connect the wires

C1

and

C2

directly together and dis-

connect them again after reaching the desired state

(MASTER or SLAVE).

When the wires

C1

and

C2

will be connected together,

a relay click can be heard.

After 5 seconds you can hear a relay click, the actuator

is set to MASTER with one connected SLAVE.

After 10 seconds a further relay click can be heard, the

actuator is now set to SLAVE.

¾

Disconnect the actuator from power supply!

¾

After individual programming, separate the wires

C1

and

C2

and connect the two actuators in accordance with

1.4.2. RESET-run

A RESET-run should be carried out,

●

if the opening width of the closed actuator at the window

is outside the RESET-range.

● if the MASTER

/

SLAVE setting needs to be reset.

¾

Disconnect the actuator(s) from power supply!

¾

Connect the wires

C1

and

C2

of each actuator directly

with each other.

¾

Drive each actuator in direction “CLOSE” (

S

= “

–

”

O

= “

+

”)

and let it be cut-off in the end position!

¾

Again disconnect the actuator(s) from power supply and

disconnect the wires

C1

and

C2

!

Ô

The zero point is set.

Ô

In case of “synchro capable” actuators, the operating

mode is reset to “single operation” by the RESET-run.

In this mode, the actuators can be operated standa

-

lone.