8

Change the oil as described in the following steps:

1. Be sure that cylinder is fully retracted and that the air line is

disconnected.

IMPORTANT:

The 5 gallon [18,9 liter] hydraulic reservoir holds

approximately 4.2 gallons [15,9 liters] of oil when filled to the

proper level with cylinder fully retracted and motor off. Dispose

of used oil in accordance with all applicable laws and regulations.

2. Loosen and remove oil drain plug at bottom of reservoir.

Allow used oil to drain into a suitable container.

3. Clean and reinstall oil drain plug.

4. Remove, clean and reinstall the reservoir air breather. It is

located on the reservoir top cover plate, under the air filter/

regulator assembly.

5. Loosen oil fill plug at top of reservoir. Slowly fill the reservoir

until the oil level is about 1 inch [25 mm] below top of

reservoir. Use Simplex hydraulic oil or a suitable equivalent

that meets the specifications shown in Table 8.

6. Reinstall oil fill plug.

7. Remove the old oil filter and replace it with a new one of

the proper specifications. Catch any spilled oil in a suitable

container.

8. Raise and lower the cylinder several times to check for

proper operation before placing the jack back into service.

RAISE

LOWER

Oil Fill Plug

Oil

Filter

Oil Drain

Plug

Air Breather

(under filter/

regulator)

Figure 6, Oil Change

6.3 Air Line Filter/Regulator (See Figure 7)

Every 30 hours of operation:

• Check the filter bowl for water. Drain any water if present.

• Inspect air filter element (inside filter bowl). Replace filter

element if dirty.

6.4 Air Line Lubricator (See Figure 7)

Before each use, check the fluid level in the air line lubricator

and add additional lubricant if needed. Use an SAE 10 [ISO 32]

detergent oil or an approved antifreeze lubricant.

Check for an oil drip speed of approximately 3 drops per minute.

Adjust if necessary.

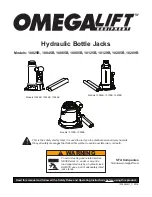

Air Line

Lubricator

Air Regulator

Filter Bowl

Lubricant

Reservoir

Drip Adjustment

Fill Plug

Water Drain

Figure 7, Air Line Lubricator and Filter/Regulator

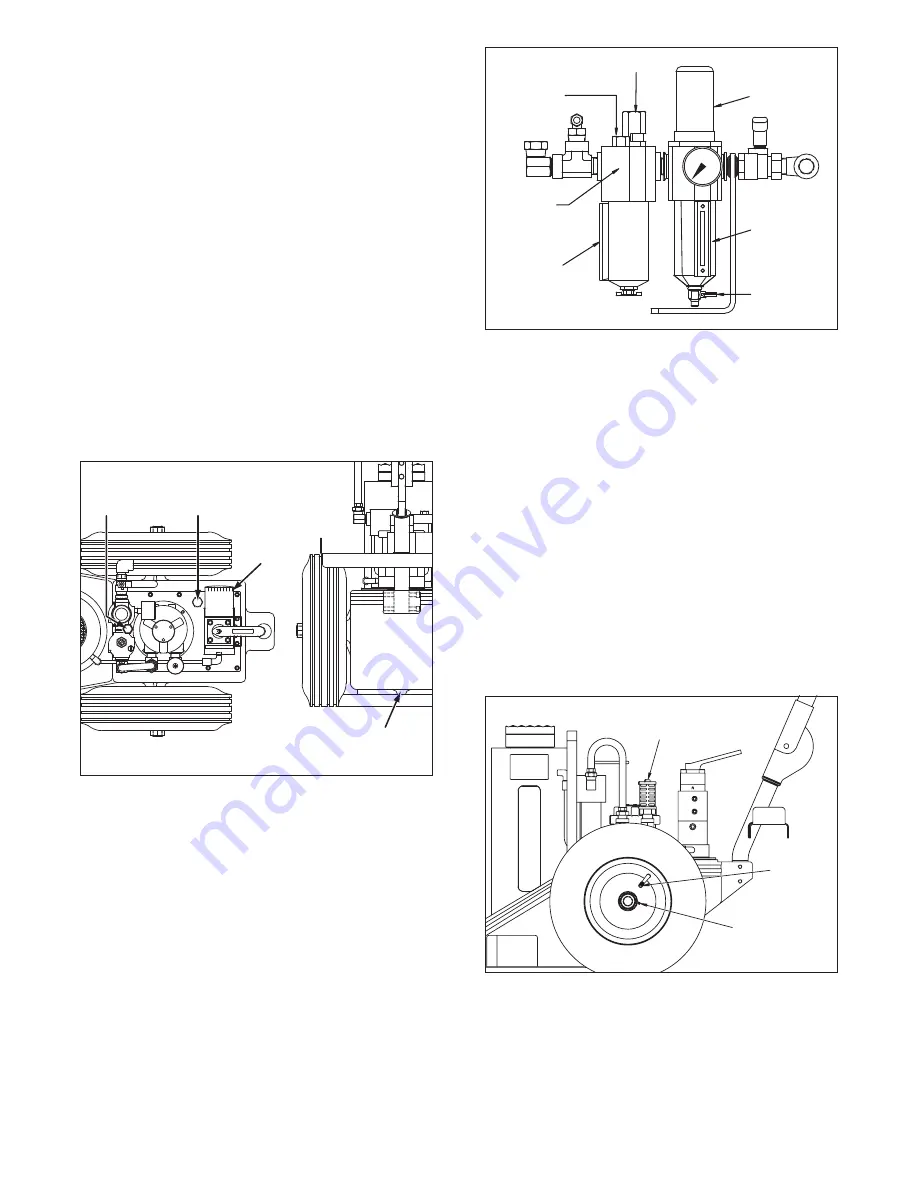

6.5 Air Muffler (See Figure 8)

Every 30 hours of operation:

• Check the air muffler for dirt or debris. If clogged, replace the

muffler with a new one of the same specifications.

Note:

Air muffler design and appearance will vary. On jacks

equipped with a Gast manufactured air motor, the felt pads

inside the muffler can be removed, cleaned and replaced.

6.6 Wheels and Tires (See Figure 8)

Every 30 hours of operation:

• Check the tires for wear or damage. Replace as required.

• Check the tire inflation pressure. Each tire should be inflated to

90 psi [6,2 bar].

Every 12 months:

• Lubricate both wheel bearings with a high quality wheel

bearing grease. Each wheel hub contains a grease fitting.

Tire Air

Valve

Wheel Bearing

Grease Fitting

Air Muffler

(appearance may vary)

Figure 8, Additional Maintenance Items