••• 3 •••

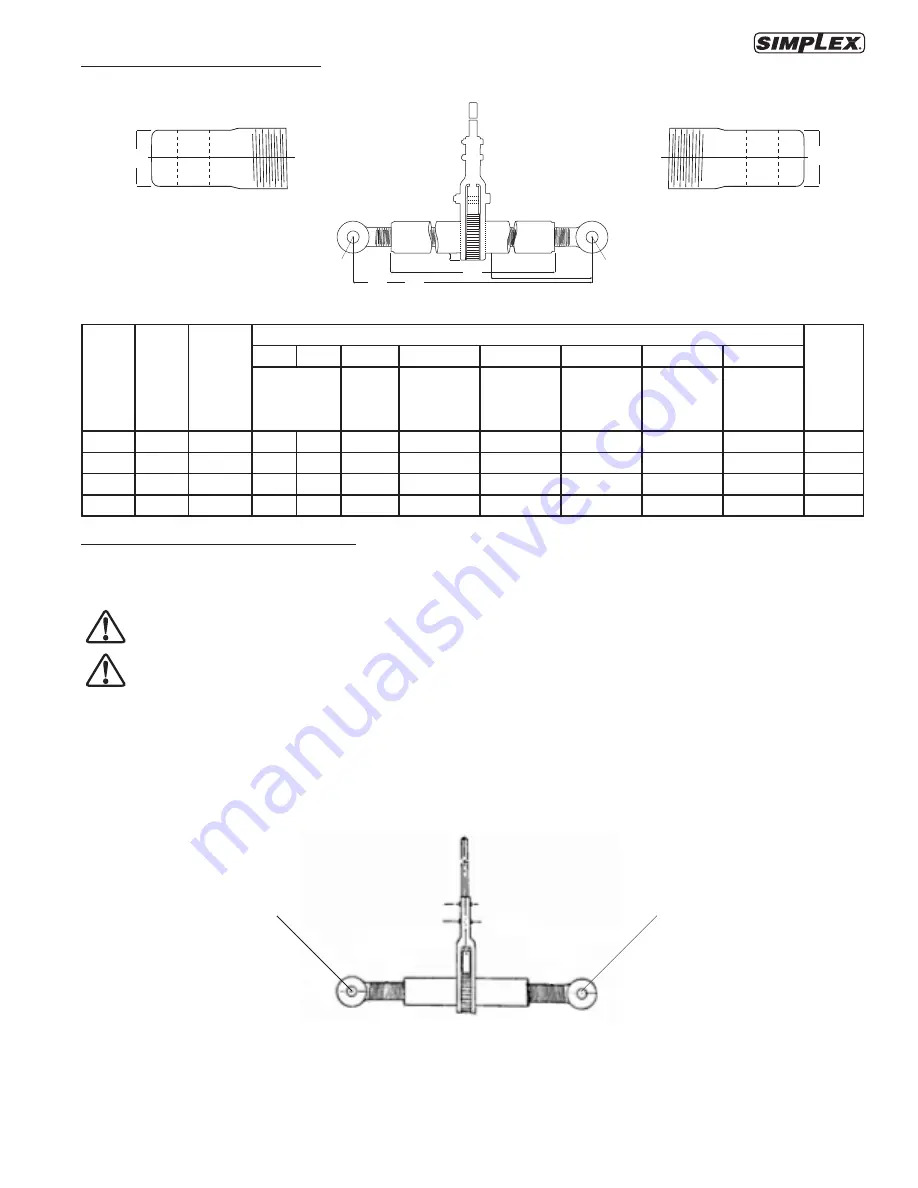

2.0 TECHNICAL SPECIFICATIONS

Model

Travel

Length

(mm)

Screw

Diameter

(mm)

Dimensions (mm)

Weight

(kg)

A

B

C

D

E

F

G

H

Eye to Eye

Barrel

Width

Left/Right

Screw

Length

Left/Right

Screw Eye

Thickness

Ratchet

Socket

Length

Inner

Diameter

Left/Right

Screw Eye

Radius

SER10

356

51

585

939

457

279

48

19

33

44

25,9

SER20

508

51

737

1244

610

356

48

19

33

44

29,9

SER30

660

51

889

1548

762

432

48

19

33

44

33,6

SER40

965

51

1194

2159

1067

584

48

19

33

44

41,7

3.0 JACK OPERATING INSTRUCTIONS

Position load binder so it can be operated from the ground or in a manner where your footing is secure. Make sure that the jack is rigidly and se-

curely attached at the eyelet connection (1). The Ratchet Load Binder pawl has two positions for expansion or pulling application.

DANGER

: These jacks are not equipped with safety stops. Do not exceed the maximum screw extensions shown in the table

(section 2.0). Exceeding travel length could cause thread failure and a personal injury hazard.

WARNING

: Before exerting handle effort on the lever bar, check to make certain that the pawl is engaged into the full tooth depth of the

ratchet wheel.

E

E

Left - Side View

Right - Side View

G

H

A

B

D

C

F

1

1

Front View