Features & Controls

9

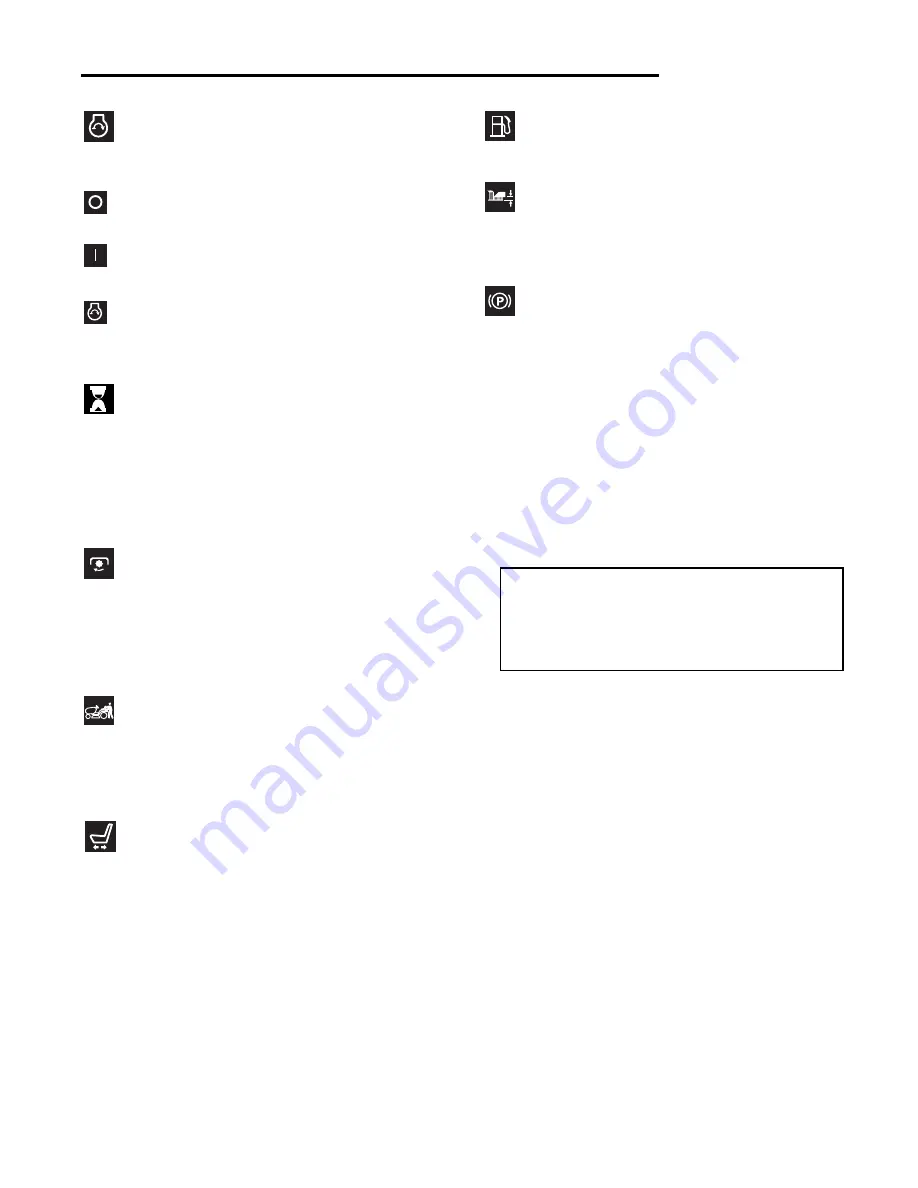

Ignition Switch

The ignition switch starts and stops the engine; it has

three positions:

OFF

Stops the engine and shuts off the

electrical system.

RUN

Allows the engine to run and powers the

electrical system.

START

Cranks the engine for starting.

NOTE: Never leave the ignition switch in the RUN posi-

tion with the engine stopped–this drains the battery.

Hour Meter

The hour meter measures the number of hours the key

has been in the RUN position.

Note: The hour meter will register the passage of time

when the engine is running. The hour meter has a self

contained power source so the total hours are always

visible.

PTO Switch

The PTO (Power Take-Off) switch engages and disen-

gages the mower blade clutch. To engage the PTO, pull

UP on the switch. Push DOWN to disengage. Note that

the operator must be seated firmly in the rider seat for

the PTO to function.

Transmission Release Valves

The transmission release valves deactivate the transmis-

sions so that the unit can be pushed by hand. See

PUSHING THE UNIT BY HAND for operational informa-

tion.

Seat Adjustment Knobs

The seat can be adjusted forward and backward. See

SEAT ADJUSTMENTS for adjustment information.

Fuel Tank Cap

To remove the cap, turn counterclockwise.

Mower Cutting Height Adjustment Lever

The mower cutting height is adjustable from 1-1/2” to 4”, in

1/2” increments. See CUTTING HEIGHT ADJUSTMENT

for adjustment information.

Parking Brake

The parking brake is incorporated into the left motion con-

trol lever. Locking the lever into the neutral locked position

engages the parking brake; moving the lever out from the

neutral locked position disengages the brake.

Note: Both motion control levers must be locked into the

neutral lock position together, or the unit will stall.

IMPORTANT

The figures and illustrations in this manual are

provided for reference only and may differ

from your specific model. Contact your dealer

if you have questions.