Lubrication (Continued).

Idler Arm Pivot

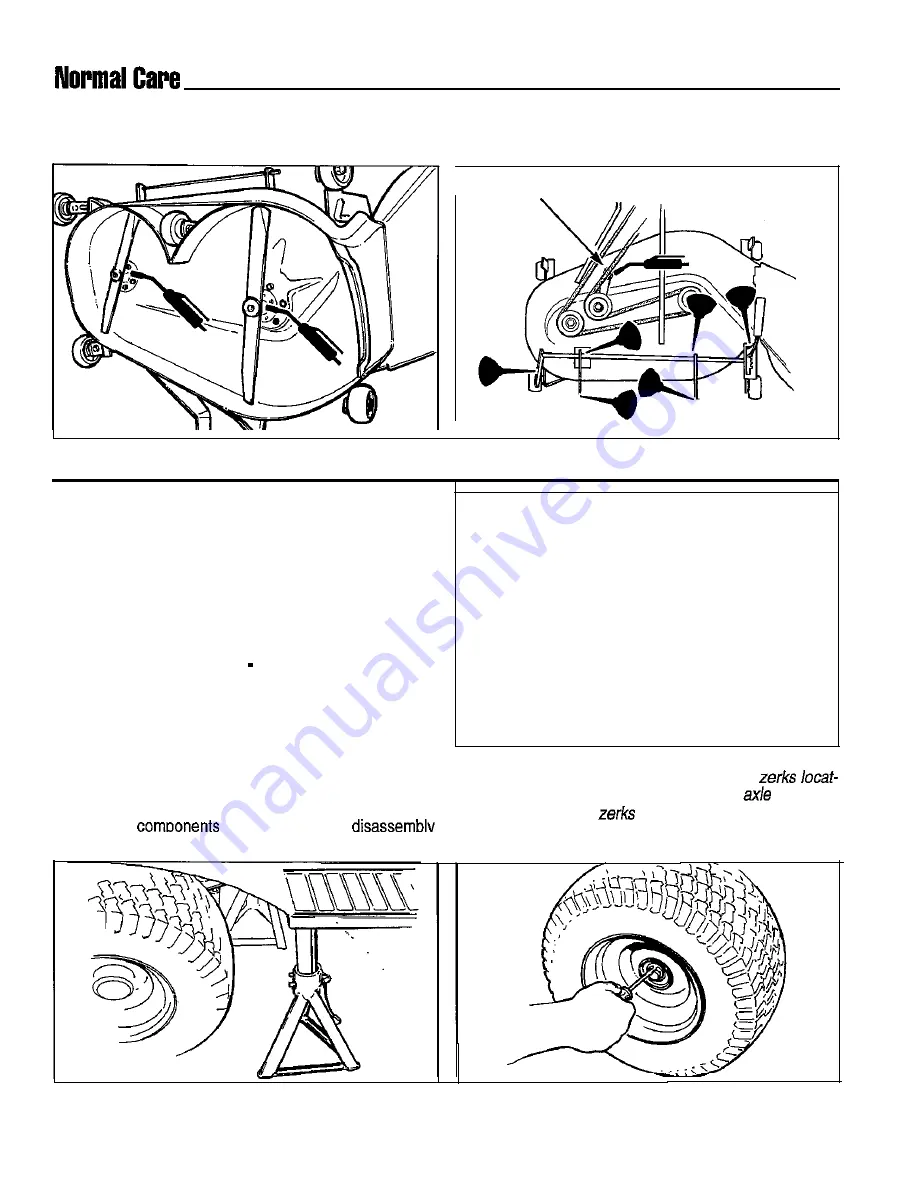

gure 15. Lubricating Mower Deck (36” shown)

Figure 16. Lubricate Deck Linkage (36” shown)

LUBRICATE THE AXLE SHAFTS

We recommend removing the rear wheels and lubricat-

A

WARNING

ing the axle shafts yearly. This prevents the wheel from

seizing onto the axle shaft, making future service easier.

PREVENT SERIOUS INJURY OR

DEATH FROM FALLING UNIT

1. Remove the key and disconnect the spark plug wire

while working on the unit.

Always use a properly working lifting device with

2. Engage the parking brake and block the front wheels.

a capacity suitable for the weight of the unit

3. Using a jack or chain hoist positioned at the center of

being serviced.

the rear frame, carefully jack the unit up until the rear

Always use a jack stand to support the unit while

tires are approximately 1” 2” off the ground.

performing service, and chock remaining wheels

NOTE: For overall unit stability during service, do not

to prevent the unit from rolling off the supports.

jack rear end higher than required for wheel removal.

Never work under or around an elevated unit that

4. Support the rear of the unit on jackstands positioned

is not properly supported and secured in posi-

under the rear frame (see Figure 17).

tion with wheel chocks.

5. Remove the plastic hub cap/axle cap.

6. Remove e-ring using a screwdriver (see Figure 18).

7. Remove the washers and wheel assembly.

NOTE: Gear drive models also have grease

8. Lubricate the axle shaft with anti-seize compound.

ed in the transmission casing beneath the

bearings.

9. Reinstall

in reverse order of

Lubricate the grease

once a year.

and lower the unit.

Figure 17. Supporting the Tractor

Figure 16. Rear Wheel Removal

1 6

0 1