1.

Product Overview

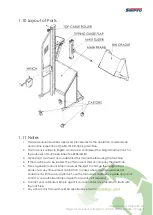

Congratulations on your purchase of an Ezi-MT bin-tipping

machine from Simpro. Ezi-MT is a light-duty manual bin

tipper, designed for low volume users. It is

environmentally friendly and perfect for those on

constrained budgets, such as schools, cafes,

small businesses, and local councils.

Ezi-MT uses the same reliable

tipping action found on other

Simpro products, but with a

difference: it is powered by

renewable energy, supplied by

the user! The innovative hand-

cranked design allows full

workplace safety compliance,

with no expensive hydraulic

machinery.

Like other Simpro tippers, Ezi-MT always keeps the weight

of the bin within the footprint of the machine to ensure

stability. It can empty wheelie bins and carts weighing

up to 65kg.

Whole-of-life environmental impact was considered from

the start of the Ezi-MT design process, to create a truly

eco-friendly product. The unique single-mast design

uses 50% less steel than competing products, and is

shipped flat-packed to reduce carbon emissions

from shipping. The Ezi-MT has no powered

components, generates no electronic waste,

and is completely recyclable.

Yet the Ezi-MT is also remarkably durable and can

be used outdoors for many years with little or no maintenance.

As workplace safety becomes ever more important, the Simpro Ezi-MT

means there is no longer any excuse for lifting your heavy bins by hand!

Summary of Contents for Ezi-MT

Page 1: ...User Manual Simpro Ezi MT Original Instructions English v40 0 October 2022 USER MANUAL...

Page 3: ...User Manual Simpro Ezi MT Original Instructions English v40 0 October 2022 Page 2...

Page 29: ...User Manual Simpro Ezi MT Original Instructions English v40 0 October 2022 Page 28...

Page 33: ...User Manual Simpro Ezi MT Original Instructions English v40 0 October 2022 Page 32...

Page 34: ...9 Notes...

Page 35: ...User Manual Simpro Ezi MT Original Instructions English v40 0 October 2022 Page 34...