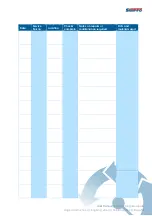

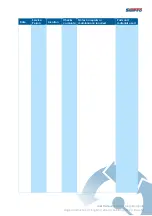

6.4

Annual inspection

The following inspection should be carried out every 12 months, and the results recorded in

the log sheet on the following page.

Annual Inspection Checklist

Category

No. Item

Check

General

1

Entire machine

Conduct a complete tipping cycle and check for

any faults or abnormal behaviour.

Hydraulic

systems

2

Hydraulic rams

Check there are no oil leaks.

3

Oil reservoir

Drain and replace the hydraulic fluid as per

specifications in

. Clean the fluid intake filter.

4

Lowering valve

Remove and clean.

Electrical

systems

5

Power lead (if

fitted)

Check that the lead is in good condition.

Safety systems 6

Door interlock

actuators

Check that the actuators are securely attached to

the door with security screws, and enter the

interlocks freely and smoothly, without force.

Check that the actuators lock the door while the

cradle is raised above 100mm.

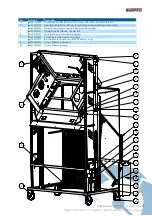

Mechanical

systems

7

Lifting chains

Check the length and condition of the lifting

chains.

If the length is outside the allowable tolerance, or

there are signs of corrosion or wear, they should be

replaced.

Lightly lubricate with silicone spray.

8

Ram rollers

Lightly lubricate with silicone spray.

9

Follower rollers

Lightly lubricate with silicone spray.

10

Inside masts

Lightly lubricate with silicone spray.

11

Roller arms

Lightly lubricate with silicone spray.

12

Door hinges

Lightly lubricate with silicone spray.

13

Cradle axles

Lightly lubricate with silicone spray.

14

Castor wheels

Check that the castor wheels are running smoothly

and the brakes working correctly.