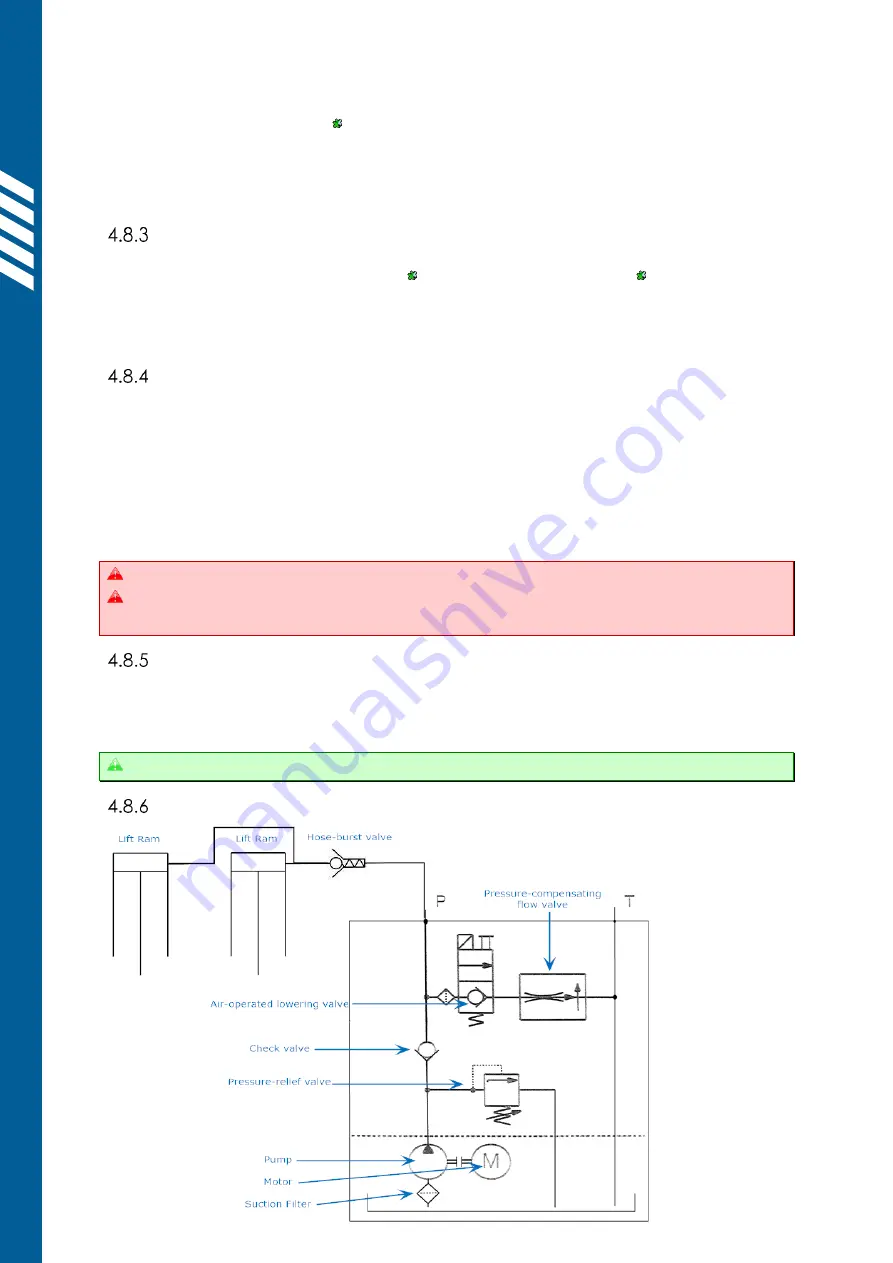

4.8.2.4

Lowering-speed valve

This is a pressure-compensating valve which limits the maximum flow rate of oil passing back

to the reservoir through the lowering valve

–

thus regulating the descent speed of the cradle

(regardless of the weight of the bin).

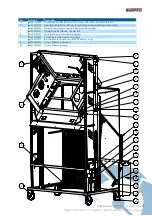

Lift rams

The MegaDumper has two lift rams of the single-action displacement type. Each ram has a

1¼ -inch chrome bar, a single rubber seal

, and two ram rollers

transfer motion into the lifting chains. Hydraulic lines run from the powerpack to the lift rams.

The rams are very robust and reliable, but easy to maintain should the need arise.

Hydraulic fluid

The hydraulic system is designed to use a mineral oil-based fluid with a viscosity grade of 22

(ISO VG22). Fluid with a higher viscosity grade may be used, but this will reduce the lowering

speed of the cradle and increase the likelihood of jams.

The hydraulic fluid should have physical lubricating and chemical properties as specified by:

-

Mineral Oil Based Hydraulic Fluids HL (DIN 51524 part 1)

-

Mineral Oil Based Hydraulic Fluids HL P (DIN 51524 part 2)

Ensure the cradle is completely lowered before replacing the hydraulic fluid.

The hydraulic reservoir has markings showing the recommended fill level. Do not fill

beyond this level unless specifically instructed by the manufacturer.

Maintenance

After every 12 months of operation the hydraulic fluid should be drained and replaced, as

per specifications in

. The intake suction-filter and the lowering valve should also be

removed and cleaned at this time.

See

for other preventative maintenance inspection procedures.

Hydraulic system schematic