20- ENG

FRAME (DEFECTS IN MATERIAL AND WORkMANSHIP)

One (1) year from date of purchase.

ACCESSORIES (DEFECTS IN MATERIAL AND WORkMANSHIP)

Includes nozzles, hoses, spray guns, wands

Ninety (90) days from date of purchase.

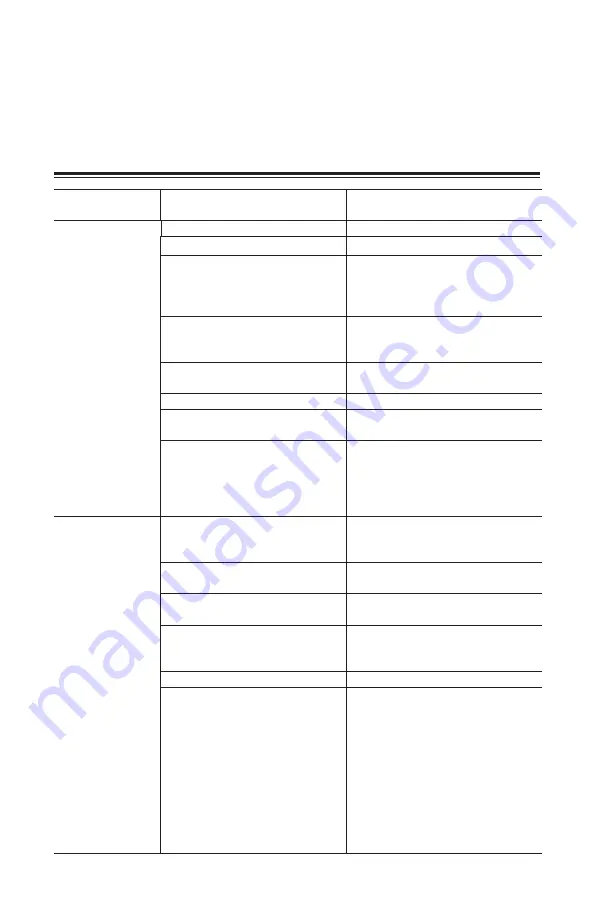

TROUBLE SHOOTING GUIDE

OPERATIONAL

ISSUE

POSSIBLE CAUSE

SOLUTION

Engine will

not start (see

Engine Manual

for further

engine

troubleshooting)

No fuel.

Add fresh fuel.

Low oil.

Add required amount of oil.

Air filter filled with oil.

Clean and/or replace

filter element. Refer to to

Engine Owners Manual

for correct procedure.

Pressure builds up after

two pulls on the recoil

starter or after initial use.

Squeeze gun trigger to relieve

pres sure.

Choke lever in the "No

Choke" position.

Move choke to the "Choke"

po si tion.

Spark plug wire not attached. Attach spark plug wire.

Engine switch in OFF

po si tion.

Place engine switch

in ON position.

Choke lever in the "Choke"

position on a "hot" engine

or an engine that has been

exposed to thermal heat

for a long period of time.

Move choke to the "No Choke"

po si tion.

No or low

pressure

(initial use)

Spray wand not in

high pressure.

See

how to Use Spray

Wand

instructions in the

Operation

Section.

Low water supply.

Water supply must be at

least 5 gpm @ 20 psi.

Leak at high pressure

hose fitting.

Repair leak. Apply sealant tape

if necessary.

Nozzle obstructed.

See

Nozzle Cleaning

instructions in the

Maintenance

section.

Water filter screen clogged.

Remove and clean filter.

Air in hose.

Turn off the engine, then the

water source. Disconnect the

water source from the pump

inlet and turn the water source

on to remove all air from the

hose. When there is a steady

stream of water present, turn

water source off. Re- con nect

water source to pump inlet and

turn on wa ter source. Squeeze

trigger to re move re main ing air