Drawing file

163

851--164300 / C

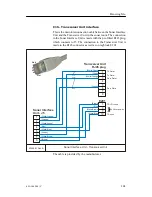

Transceiver Unit to Motor Control Unit

This is the main intercommection cable between the SH80

Transceiver Unit and the Motor Control Unit on the Hull Unit. The

connections to both the Transceiver Unit and the Motor Control

Unit are made on terminal blocks.

W236 / Rev.A

Transceiver Unit - Motor Control Unit

1

32

54

3

28

2

30

4

26

42

5

24

40

7

20

36

6

22

38

8

18

34

9

16

11

12

10

14

12

10

13

8

14

6

15

4

2

1R

1R

1BL

2R

2BL

1BL

3R

3BL

4R

4BL

5BL

6BL

7BL

5R

6R

7R

2R

2BL

3R

3BL

4R

4BL

5R

5BL

6R

6BL

7R

7BL

Transceiver Unit E201

Motor Control Unit E301

1

1

2

2

3

3

4

4

5

5

6

6

7

7

24 Vdc s)

24 Vdc standby (-)

Hoist

Lower

Upper limit switch

Lower limit switch

Rotation sensor

PU ground

Motor overload switch

+12 Vdc

+12 Vdc

Stabilisation Tx

TRU Ground

Stabilisation Rx

Conductors

8 x (2+1) x 0.5 mm2

Screen

Overall braided

Voltage

60 V

Max.diameter

14 mm

Summary of Contents for SH80 - REV C

Page 2: ......

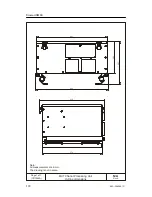

Page 14: ...Simrad SH80 X 851 164300 C Blank page...

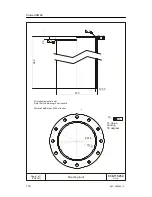

Page 61: ...Transceiver unit 45 851 164300 C Figure 13 Mounting the Transceiver Unit CD3110A...

Page 196: ...Notes...

Page 197: ...Notes...

Page 200: ......