the chilled water system shuts down during summer. The lower temperature in a heating system is often the

ambient temperature at fill conditions(for example, 50

o

F or 10

℃

).

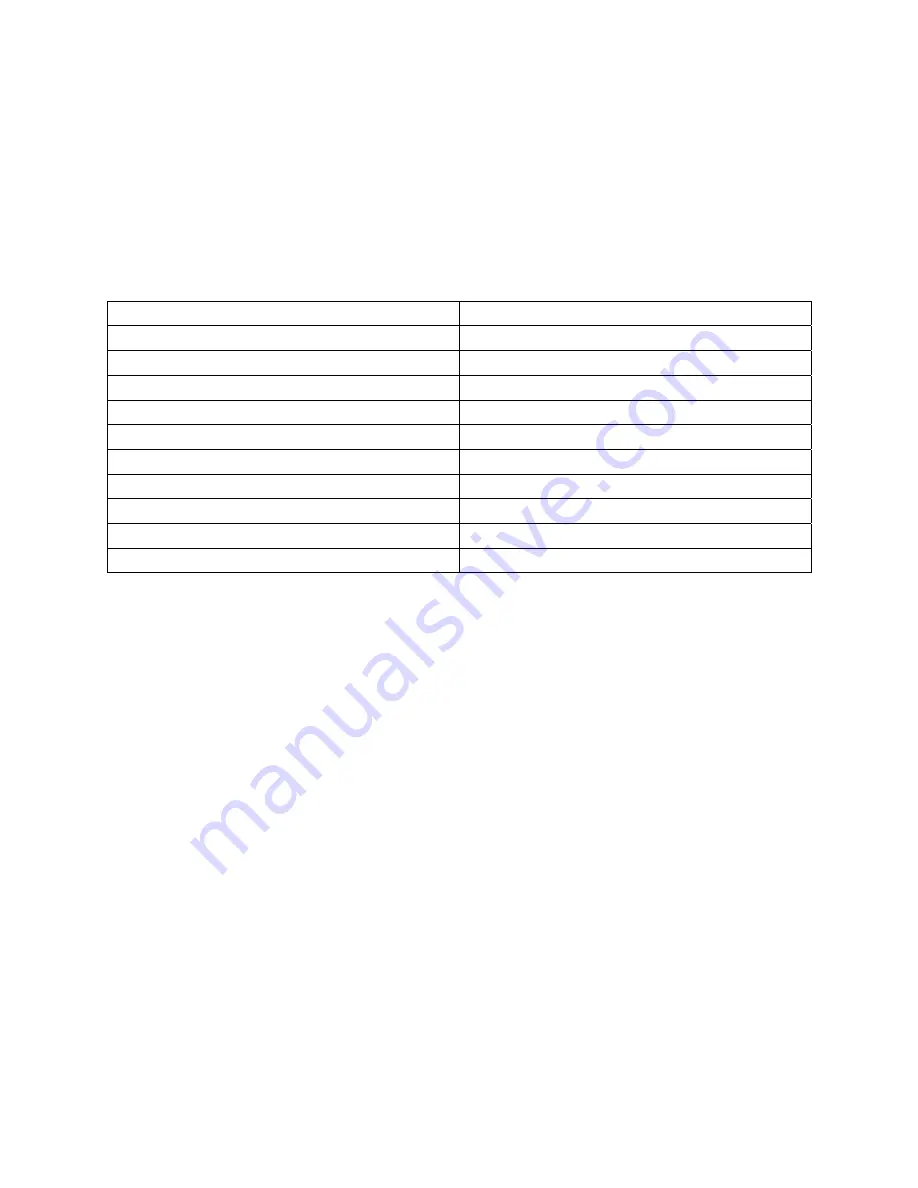

h). Water quality control

When industrial water is used as chilled water, little furring may occur; however, well water or river water,

used as chilled water, may cause much sediment, such as furring, sand, and so on. Therefore, well water or

river water must be filtered and softened in softening water equipment before flowing into chilled water

system. If sand and clay settle in the evaporator, circulation of

chilled water may be blocked, and thus leading to freezing accidents; if hardness of chilled water is too high,

furring may occur easily, and the devices may be corroded. Therefore, the quality of chilled water should be

analyzed before being used, such as PH value, conductivity, concentration of chloride ion, concentration of

sulfide ion, and so on.

PH 6-8

Total hardness

less than 50 ppm

Electrical conductivity

less than 200 mV/cm (25

°

C)

Sulfide ion

none

Chlorine ions

less than 50 ppm

Ammonia ions

none

Sulfate ion

less than 50 ppm

Silicon

less than 30 ppm

Total iron

less than 0.3 ppm

Sodium ion

No requirement

Calcium ion

less than 50 ppm

Filling the installation

-

Before filling, check that the installation drain cock is closed.

-

Open all installation and terminal air vents.

-

Open the gate valves.

-

Begin filling, slowly opening the water filling cock outside the unit.

-

When water begins to leak out of the terminal air vent valves, close them and continue filling until the

pressure gauge indicates a pressure of 1.5 bars.

Emptying the installation

-

Before emptying, place the mains switch in the

“

off

”

position.

-

Make sure the installation fill/top-up water cock is closed.

-

Open the drain cock outside the unit and all the installation and terminal air vent valves.

36

Summary of Contents for SCV-100EA

Page 1: ...SCV xxEA SERVICE MANUAL AIR COOLED MINI CHILLER UNIT AIR CONDITIONING...

Page 16: ...7 Wiring Diagram SCV 50EA SCV 70EA 14...

Page 17: ...SCV 100EA 15...

Page 18: ...SCV 120EA SCV 140EA SCV 160EA 16...

Page 28: ...11 Water Pressure Drop SCV 50EA SCV 70EA SCV 100EA Heat exchanger pressure drop water side 26...

Page 29: ...SCV 120EA SCV 140EA 27...

Page 30: ...SCV 160EA 28...

Page 88: ...18 Optional Accessories No Name Specification Remark 1 Wired controller KJR 120F Customized 86...

Page 91: ...Exploded view of unit SCV 50EA 22 7 22 6 22 5 22 4 22 2 22 1 22 3 89...

Page 94: ...Exploded view of unit SCV 70EA 22 7 22 6 22 5 22 4 22 2 22 1 22 3 92...

Page 97: ...Exploded view of unit SCV 100EA 25 1 25 2 25 3 25 6 25 7 25 4 25 5 25 9 25 8 95...

Page 100: ...Exploded view of unit SCV 120EA 25 1 25 2 25 3 25 4 25 5 25 6 25 7 25 9 25 8 25 10 25 11 98...

Page 103: ...Exploded view of unit SCV 140EA 25 1 25 2 25 3 25 4 25 5 25 6 25 7 25 9 25 8 25 10 25 11 101...

Page 106: ...Exploded view of unit SCV 160EA 25 1 25 2 25 3 25 4 25 5 25 6 25 7 25 9 25 8 25 10 25 11 104...