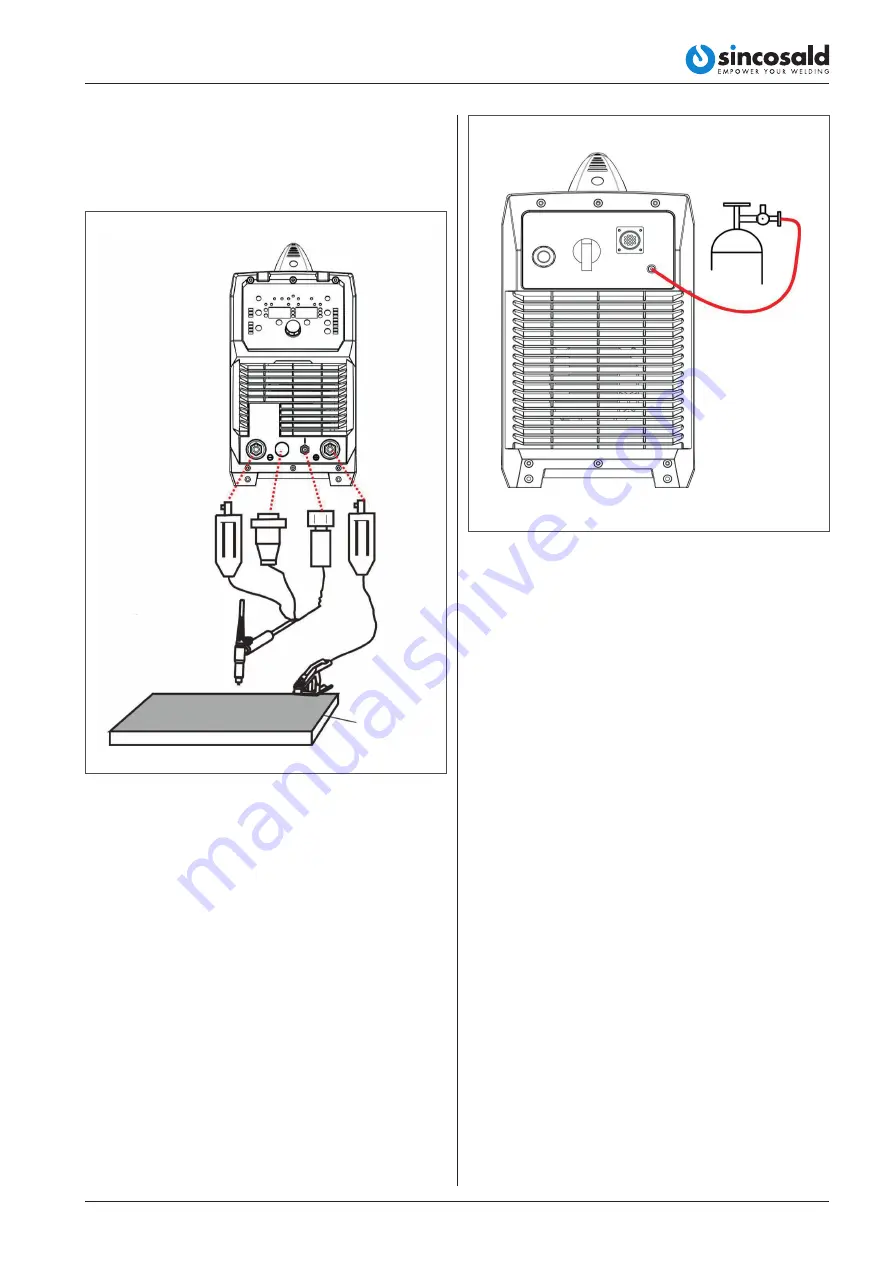

5. Connect the gas regulator to the Gas Cylinder

and connect the gas line to the Gas Regulator.

6. Connect the gas line to the machine inlet gas

connector via the quick push lock connector

located on the rear panel. Check for Leaks!

7. If using a water cooled torch, Connect the water

cooling lines from the TIG torch to the front of the

water cooler, ensuring the red and blue return

and supply lines match the connectors.

8. If using a water cooled torch, connect the water

cooler interface cable from the rear of the power

source to the rear of the water cooler.

9. Open gas cylinder valve and adjust regulator,

flow should be between 5 10 l/min depending

on application. Re check regulator flow pressure

with torch valve open as static gas flow setting

may drop once gas is flowing.

10. Each machine is equipped with a power cable

should be based on the input voltage welding

power cable connected to the appropriate

position, not to pick the wrong voltage;

11. With the corresponding input power supply

terminal or socket good contact and prevent

oxidation;

12. With a multi meter measure the input voltage is

within the fluctuation range;

13. The power ground is well grounded.

Note:

•

Secure the gas cylinder in an upright position by

chaining them to a stationary support to prevent

falling or tipping.

6.4. INSTALLATION & OPERATION FOR

TIG WELDING

6.4.1. Set up installation for TIG Welding

Workpiece

Welding

Gun

Switch the ON/OFF Switch (located on the rear panel)

to OFF.

1. Connect the TIG torch cable to “-”, tighten

clockwise.

2. Connect TIG torch remote plug to remote socket

ensuring all connections are tight.

3. Connect TIG torch gas connection to the TIG gas

outlet , ensuring all connections are tight.

4. Connect the earth lead to “+”, tighten clockwise;

Connect the earth clamp to the work piece.

Contact with the work piece must be firm contact

with clean, bare metal, with no corrosion, paint or

scale at the contact point.

25

1.995.229 EN - Rev. 1.1

NOVATIG 403 DC PULSE