36

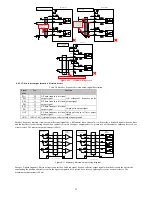

100Ω

PULSE+

PULSE-

33

34

SIGN+

SIGN-

31

32

16

PULHIS

PULS

[CW A phase]

SIGN

[CCW Bphase]

Torque

instruction

8

23

37

38

9

24

39

10

DO1

DO1-

DO2

DO2-

DO3

DO3-

DO4

DO4-

Status

output

Encoder

Dividing

pulse output

- Difference

PE

PA+

PA-

PB+

PB-

PZ+

PZ-

28

13

12

27

26

GND

29

11

35

42

Upper

computer

GND

Encoder Z-phase

open-collector output

GND

OCZ

+5V

+5V

GND

6

43

GND

AO1

Analog 1 output

Analog 2 output

15

29

30

29

GND

GND

AI2

AI1

1

EA100

Servo drive

Servo ready

Brake output

Location arrival

Fault output

Torque

limit

PE

Torque limit 0 ~ 10V

Input impedance about:

9kΩ

Torque limit -10 ~ 0V

Input impedance about:

9kΩ

In 5V power

supply, the maximum

allowable current 200mA

PULHIP

+24V

+24V电源

25

COM+ 21

DI1

5

DI2

20

4

DI3

19

3

18

2

DI4

DI5

DI6

DI7

17

DI8

ALM-RST

INHIBIT

P-OT

N-OT

GNUMO

GNUM1

S-ON

P-CLR

COM

State

input

7

Servo enable

Alarm reset clear

Pulse Deviation counter clear

Pulse inhibit

Forward Drive inhibit

Reverse drive inhibit

Electronic gear ratio numerator

selection 0

Electronic gear ratio numerator

selection 1

S-RDY

BK

COIN

ALM

2KΩ

2KΩ

A

GND

AO1

A

100Ω

100Ω

100Ω

Figure 4-26 standard torque mode control circuit wiring diagram

4.9 Control circuit wiring precaution

Encoder cable routing must be separated from the power cable routing by at least 30cm or more.

If the control circuits need to extend, make sure the shield is reliable connected.

In the servo drive, + 24V COM and + 5V reference to GND. Do not exceed the maximum allowable load current, otherwise the drive may

be broken.

Try to use the shortest command input and encoder cable.

Please use the cable more than 1.5mm

2

for grounding cable.

Must be a single-point ground.

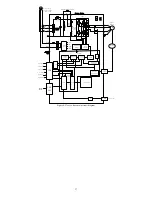

4.10 Servo drive main circuit block diagram