99

9 Fault alarm and Treatment

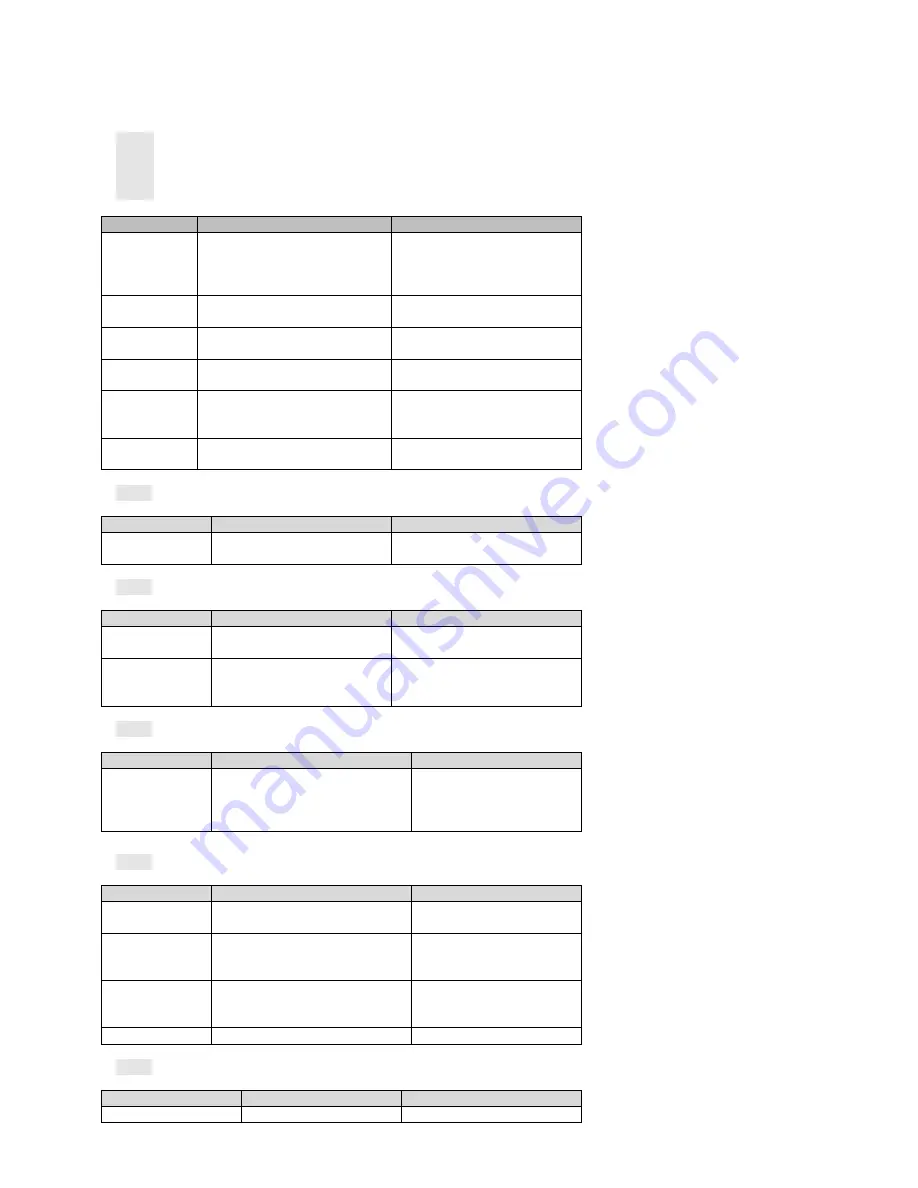

9.1Fault Diagnosis and Treatment

When a fault or alarm occurs, the servo drive will display ―

A

L

‖

Last fault can be viewed by P0-18. Fault display and treatment measures are as follows:

A

L

001

:

Short circuit

A

L

002

:

Hardware over current

A

L

003

:

Software over current

Fault Causes

Check

Solution

Short circuit of drive

output

1

:

Check the connection status between

motor and drive or if there is a short circuit

2

:

Check if the motor damaged

1

:

Exclude short circuit condition and

avoid metal conductor being exposed

externally.

2

:

Replace the damaged motor

Wiring error of the

motor

Check the wiring order of motor connected

to the drive

Re-wiring based on the wiring order

specification

Setting error of

control parameter

Check if the set value is much greater than

the factory setting value

Resume defaulted setting, and then

gradually modify

Command changes

drastically

Check if the control input command

changes too drastically

Fixed the change ratio of the input

command or initialize filter function

External braking

resistor is too small

or short circuit

Check if the external braking resistor

meets the specification

Use the braking resistor matched the

specification and set the parameters of

P8-18 and P8-20 correctly

Drive hardware fault

When all the above problems are excluded,

the fault still occurs

Send back to the dealer or the factory for

check

AL003

:

AD Initialization Fault

Fault Causes

Check

Solution

Fault of drive hardware Power to restart

,

if the fault still occurs

Send back to the dealer or the factory for

check

AL004

:

Memory Error

Fault Causes

Check

Solution

Abnormal

write

of

parameter data

Power off and restart

,

if the fault still

exists

Replace the drive

Memory

stored

too

frequently

Check the program of upper computer if

the drive‘s EEPROM is frequently

written.

Modify the program of upper computer,

changed to RAM address in case it should

be frequently written.

AL006

:

AD Sampling Fault

Fault Causes

Check

Solution

External analog

sampling deviation is

too large or timeout in

conversion

Power off and restart

,

if the fault still exists

Send back to the dealer or the factory

for check

AL007

:

Encoder Error 1

Fault Causes

Check

Solution

Encoder is loose

Check CN5 on the drive and the connector of

encoder

Re-install

Encoder wiring error

Check if the encoder wiring follows the

recommended specification as mentioned in

the manual

Wiring correctly

Encoder connection not

good

Check if CN5 on drive is well connected to

servo motor encoder, and if the shielding

layer is intact

Re-wiring

Encoder damaged

Exclude wiring problems, the fault still exists Replace the motor

AL008

:

Encoder Error 2

Fault Causes

Check

Solution

Z signal error of incremental Same with

AL007

Same with

AL007