BLINDSTITCH HEMS

Wrong Side-

of Fabric

•-Hem

Edge

-Soft

Fold

-1/4'

Creating Soft Fold

j

•

Stitch: BMndstitch *

• Stitch Width:

2

to

5

(depending on fabric)

• Needle Position:

or ^

• Stitch Length:

6

to

1 2

• Zig-Zag Plate

• Zig-Zag Foot

• Blindstitch Hem Guide

Blindstitching takes a little practice, so make

a test sample first.

Raise take-up lever to its highest position.

1. Raise presser foot, loosen presser-foot

screw, and slip blindstitch hem guide be

tween screw and shank of zig-zag foot.

Make sure underside of guide clears slide

plate and front of foot. Tighten presser-foot

screw.

2. Turn up hem in width desired. Apply ap

propriate finish to hem edge and press.

(You may want to baste the turned hem to

hold it in place. If so, be sure to place

basting at least

V

2

inch

below

top edge of

hem.)

3. Fold the hem back against right side of gar

ment, creating a soft fold about

V

a

inch

from top edge of hem on wrong side of

work. Press lightly.

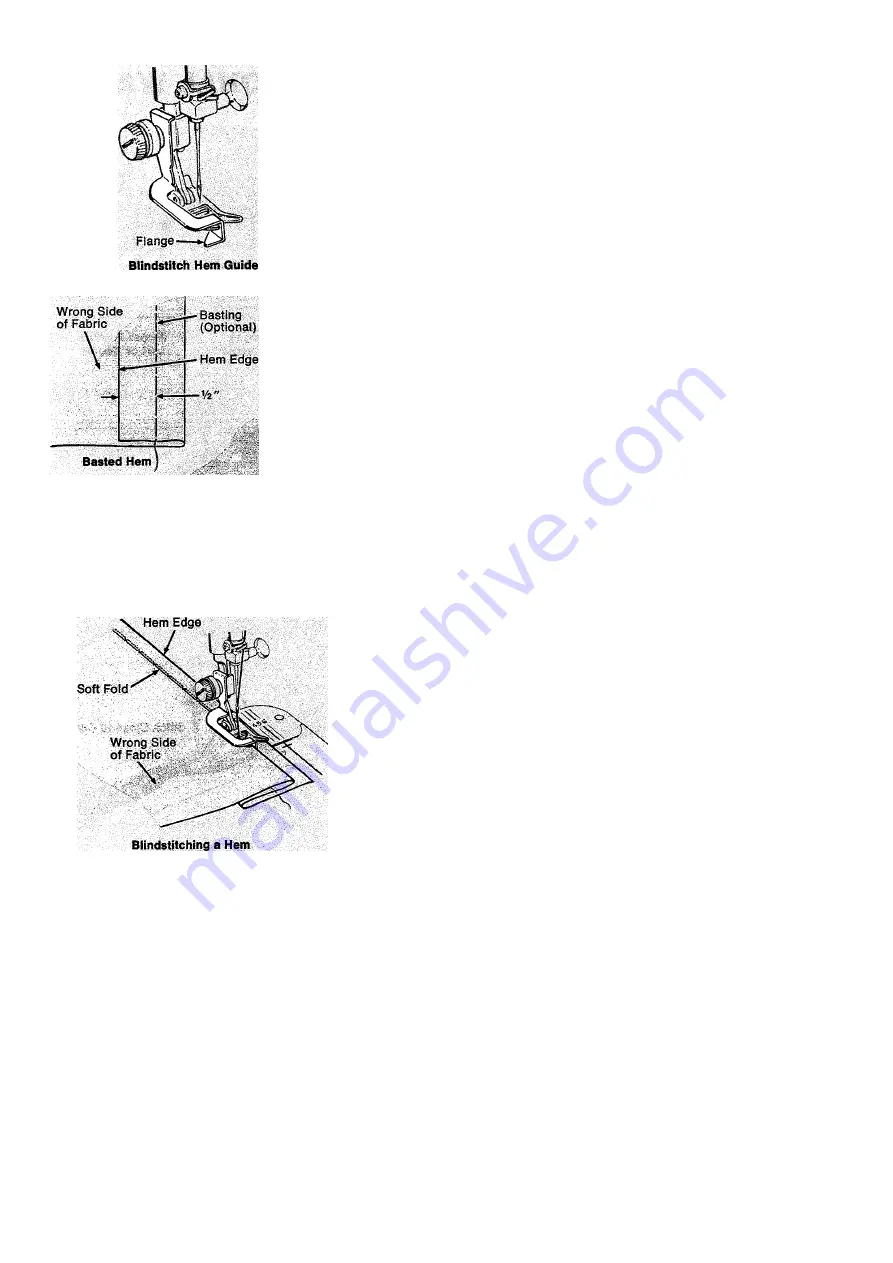

4. Position hem under foot with soft fold rest

ing against wall of guide. Make sure flange

of guide is between the soft fold and top of

hem.

5. Lower the foot and stitch so that the straight

stitches fail on the hem edge and sideward

stitches pierce the soft fold. While stitching,

guide hem edge in a straight line and feed

soft fold evenly against wall of hem guide.

6. Raise take-up lever to its highest position.

Raise presser foot and remove work (by

drawing it to the back).

NOTE: For an extended blindstitch, set the ma

chine for speed basting

but use a stitch width

setting

of 4 (instead of 5). The reduced number

of crossover stitches in the blindstitching pro

duced in this way makes the stitch particularly

appropriate for hemming knit and stretch

fabrics.

42

Instrukcje obsługi maszyn do szycia firm Polskich jak i zagranicznych np. Singer Toyota Pfaff Gritzner Łucznik Arka