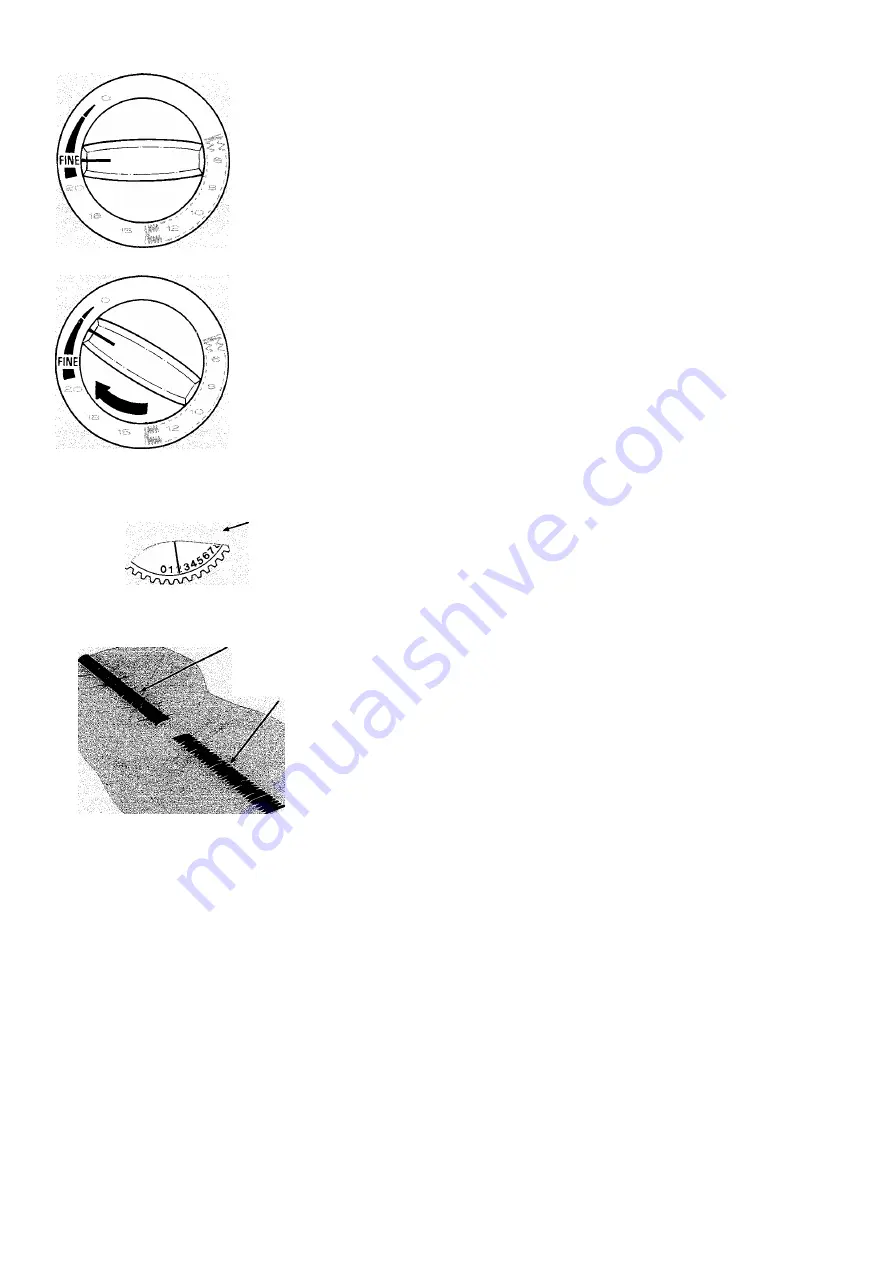

stitch Length in FÍNE Area

As Dial Is Turned, Stitches Close Up

Tension Dial

Incorrect

Correct

Adjusting Thread Tension

decorative touches

SATIN STITCHING

Satin stitching, a series of closely spaced zig

zag stitches that form a smooth, satin-like

surface, is useful for both practical and deco

rative work. The plain zig-zag stitch, for ex

ample, is suitable for appliqué when closed

up to form a satin stitch. Other built-in and

interchangeable

Fashion

Stitch patterns (as

illustrated on pages 20 and 24) can be sewn at

satin-stitch length.

When you wish to produce a satin stitch, make

a test sample first so that you can adjust the

stitch length and thread tension properly. Soft

fabric may require a backing to ensure firm

satin stitching. Crisp lawn or organdy is suit

able for this purpose. For best results, use the

special purpose foot.

• Stitch: Desired FasWon Stitch

• Stitch Width: 2 through 5

• Needle Position:

• Stitch Length:

FINE

area

• Zig-Zag Plate

• Special Purpose Foot

Adjusting Stitch Length

1. Set stitch-length dial at bottom of FINE

area.

2. Run machine at slow speed.

3. Gradually turn dial clockwise until stitches

are closely spaced and form a smooth sur

face.

Adjusting Thread Tension

Satin stitching usually requires less tension

than straight stitching and open zig-zag stitch

ing. Furthermore, the wider the satin stitch,

the lighter the tension on your thread must be.

Notice the stitching on your sample. If the

fabric is puckered, or the bobbin thread is

pulled to the fabric surface, lower the needle-

thread tension by turning the dial to a lower

number.

54

Instrukcje obsługi maszyn do szycia firm Polskich jak i zagranicznych np. Singer Toyota Pfaff Gritzner Łucznik Arka