Summary of Contents for 678B002

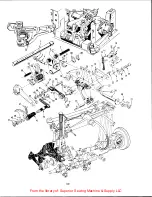

Page 1: ...SINGER 678B002 B005 B007 BOOS From the library of Superior Sewing Machine Supply LLC ...

Page 20: ...From the library of Superior Sewing Machine Supply LLC ...

Page 24: ...10 r6 9 I 24 From the library of Superior Sewing Machine Supply LLC ...

Page 30: ...30 From the library of Superior Sewing Machine Supply LLC ...

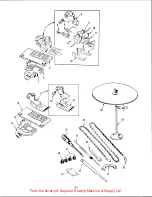

Page 32: ...32 From the library of Superior Sewing Machine Supply LLC ...

Page 34: ...34 From the library of Superior Sewing Machine Supply LLC ...

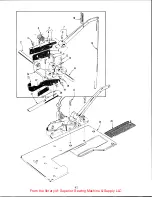

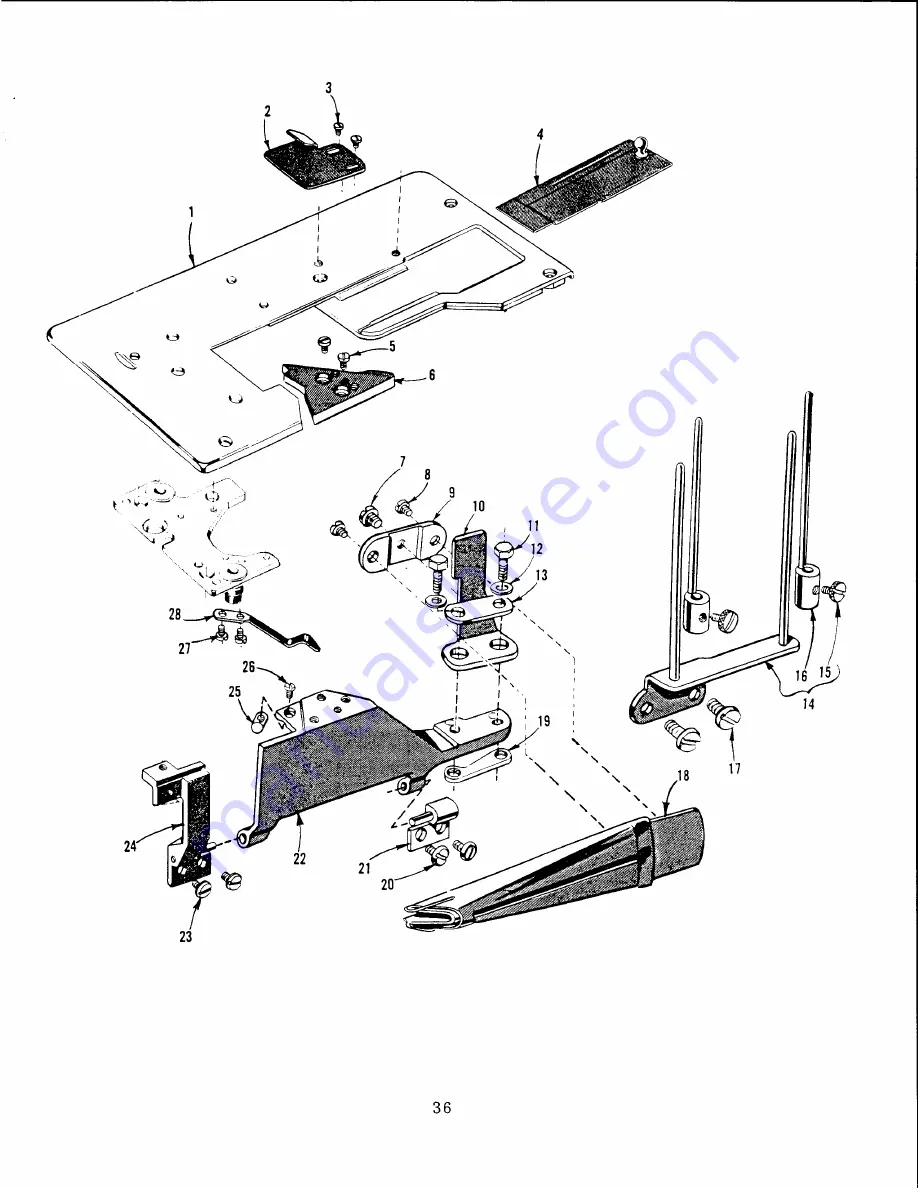

Page 36: ...2 _ v ___ I yr 21 36 4 1 I 18 11 From the library of Superior Sewing Machine Supply LLC ...

Page 38: ...38 From the library of Superior Sewing Machine Supply LLC ...

Page 40: ...4 40 From the library of Superior Sewing Machine Supply LLC ...

Page 42: ...42 From the library of Superior Sewing Machine Supply LLC ...

Page 44: ...7 33 14 18 44 From the library of Superior Sewing Machine Supply LLC ...