MACHINE MAINTENANCE

An overlock requires more frequent maintenance than a

conventional sewing machine for two reasons:

• A lot of lint is produced when the cutters are cutting the fabric.

• An overlock runs at a very high speed and needs to be oiled

frequently to lubricate the internal working parts.

Cleaning

Turn off the main power switch and unplug the machine.

Open the front cover and remove all the lint using a lint brush.

Oiling

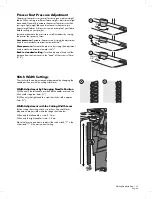

Turn off the main power switch and unplug the machine.

To keep the machine running smoothly and quietly the moving

parts, pointed out in the picture, must be lubricated often. We

recommend lubricating after every 24 hours of use.

Use sewing machine oil. Do not use any other oil, it could

damage the machine.

Wipe the machine surface to remove all excess oil before sewing.

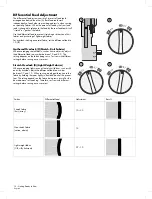

Replacing the Lower Cutter

Turn off the main power switch and unplug the machine.

The stationary lower cutter should be changed when it becomes

blunt. Change it by following the below instructions. If you are

having any difficulties, consult your service agent to make the

necessary adjustments.

• Turn off the upper cutter (A). Open the front cover.

• Loosen the lower cutter set screw (B) and remove the stationary

cutter (C).

• Place a new lower cutter in the groove of the lower cutter

holder. The blade of the lower cutter shall be flush with the

stitch plate.

• Tighten the lower cutter set screw (B).

• Turn the upper cutter (D) on again.

• Turn the hand wheel so the needles are in their lowest position.

Machine Maintenance – 23

English

Summary of Contents for S14-78

Page 32: ......

Page 64: ......

Page 65: ...IAN 290240 MACHINE À COUDRE OVERLOCK S14 78 MACHINE À COUDRE OVERLOCK Mode d emploi FR FR ...

Page 96: ......

Page 97: ...IAN 290240 OVERLOCKMACHINE S14 78 OVERLOCKMACHINE Gebruiksaanwijzing NL NL ...