61

GR

σε

καλή

κατάσταση

.

Πριν

χρησιμοποιήσετε

την

αντλία

ανάκτησης

,

βε

-

βαιωθείτε

ότι

είναι

σε

ικανοποιητική

κατάσταση

λειτουργίας

,

έχει

καλά

συντηρηθεί

και

ότι

όλα

τα

συναφή

ηλεκτρικά

εξαρτήματα

είναι

σφρα

-

γισμένα

για

να

αποφευχθεί

η

ανάφλεξη

σε

περίπτωση

απελευθέρωσης

ψυκτικού

μέσου

.

Συμβουλευτείτε

τον

κατασκευαστή

σε

περίπτωση

αμ

-

φιβολίας

Το

ανακτημένο

ψυκτικό

μέσο

επιστρέφεται

στον

προμηθευτή

ψυκτικού

μέσου

στη

σωστή

φιάλη

ανάκτησης

και

το

σχετικό

σημείωμα

μεταφοράς

αποβλήτων

τοποθετείται

.

Μην

αναμιγνύετε

ψυκτικά

μέσα

σε

μονάδες

ανάκτησης

και

ειδικά

σε

φιάλες

.

Εάν

πρόκειται

να

αφαιρεθούν

συμπιεστές

ή

λάδια

συμπιεστή

,

βεβαιωθεί

-

τε

ότι

έχουν

εκκενωθεί

σε

αποδεκτό

επίπεδο

για

να

βεβαιωθείτε

ότι

το

εύφλεκτο

ψυκτικό

μέσο

δεν

παραμένει

εντός

του

λιπαντικού

.

Η

διαδικα

-

σία

εκκένωσης

πραγματοποιείται

πριν

από

την

επιστροφή

του

συμπιεστή

στους

προμηθευτές

.

Για

την

επιτάχυνση

αυτής

της

διαδικασίας

πρέπει

να

χρησιμοποιείται

μόνο

ηλεκτρική

θέρμανση

στο

σώμα

του

συμπιεστή

.

Όταν

το

λάδι

αποστραγγίζεται

από

ένα

σύστημα

,

πρέπει

να

εκτελείται

με

ασφάλεια

.

Summary of Contents for SNG21-09IVi

Page 3: ...3 GR 1 2 3 4 5 6 7 service...

Page 4: ...4 GR R32 R32 GWP 675 R32 R32 R32...

Page 5: ...5 GR service 4m2 R32 1 band wifi 2400MHz 2483 5MHz 2 wifi 20dBm...

Page 6: ...6 GR q q q q q q q q q blue fins q...

Page 7: ...7 GR q q q q q q q q q...

Page 8: ...8 GR q q q q q q 3 q q q q...

Page 9: ...9 GR q q q q q q q NEC CEC q q q q q...

Page 10: ...10 GR q q q q q q q q q q m2 49 q...

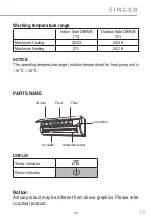

Page 11: ...11 GR DB WB C DB WB C 32 23 43 26 27 24 18 15 C 43 C Temp indicator Power indicator aux...

Page 12: ...12 GR...

Page 13: ...13 GR I Feel TURBO AUTO 8 C X FAN WiFi LIGHT...

Page 14: ...14 GR q q beep q q Light 1 ON OFF 2 MODE AUTO COOL DRY FAN HEAT AUTO AUTO FAN SWING...

Page 16: ...16 GR AUTO DRY X FAN FAN 2 AUTO FAN HEAT 2 FAN 4 SWING 2...

Page 18: ...18 GR 3 5 9 WIFI WiFi WiFi 5 WiFi WiFi MODE WiFi 1 WiFi 10 Light...

Page 22: ...22 GR I FEEL c d c d LOCK MODE d MODE d C F 1 ON OFF 2 MODE 3 c d AUTO 4 FAN 5 SWING...

Page 23: ...23 GR 1 2 7 1 5V 3 8 aux AUTO...

Page 24: ...24 GR 1 2 aux...

Page 25: ...25 GR 3 45 C 4 1 2 3 4...

Page 26: ...26 GR service 5 service 1 2 3 service 1 2...

Page 27: ...27 GR 3 8...

Page 28: ...28 GR 3...

Page 29: ...29 GR AUTO AUTO 16 C 30 C...

Page 30: ...30 GR 5 8 U8 H6 H3 E1 C5 F1 F2 F0...

Page 31: ...31 GR 210 5386490...

Page 32: ...32 GR 15cm 250 cm 15cm 300cm 15cm...

Page 33: ...33 GR 50cm 30cm 30cm 50cm 200cm...

Page 34: ...34 GR 1 2 3 4 5 6 7 8 1 2 3 4 5 6 2 5 7 8...

Page 35: ...35 GR 1 2 3 4 5 1 2 3 4 5 6 7 8...

Page 36: ...36 GR 9 R32 1 2 3 4 5 9 12 10 17 21 16...

Page 37: ...37 GR 1 2 3 1 150mm 150mm 55mm 70mm 55mm 70mm...

Page 38: ...38 GR 2 3 55 70 5 10 1 2 55 70 5 10...

Page 39: ...39 GR 1 2 3 4 1 m 1 4 15 20 3 8 30 40 1 2 45 55 5 8 60 65 3 4 70 75...

Page 40: ...40 GR 2 1...

Page 41: ...41 GR 2 3 4 5 M 9K 12K N 1 3 2...

Page 42: ...42 GR 1 2 3 4 1 2 3...

Page 43: ...43 GR 4 5 1 2 3 3...

Page 44: ...44 GR 2300W 5000W 6000W 8000W 10000W 16000W 1 2 1 2 1...

Page 45: ...45 GR 2 3 4 1 m 1 4 15 20 3 8 30 40 1 2 45 55 5 8 60 65 3 4 70 75...

Page 46: ...46 GR L N M M 9K 12K 2 1 10 2 U U...

Page 47: ...47 GR O O O...

Page 48: ...48 GR 1 2 3 0 1 4 1 2 0 1MPA 5 6 2 7 Lo Hi...

Page 50: ...50 GR 1 2 3 1 2 ON OFF MODE AUTO COOL DRY FAN HEAT 16oC 1 5 7 5 8 2 3 3...

Page 54: ...54 GR 2...

Page 55: ...55 GR R32...

Page 56: ...56 GR 1 2...

Page 57: ...57 GR 3 30 40 1 4 5 6...

Page 58: ...58 GR 7 8 Ampere...

Page 59: ...59 GR...

Page 60: ...60 GR 80...

Page 61: ...61 GR...