Copyright © 2020 LBC Bakery Equipment, Inc. 11 Rev G 10/2020

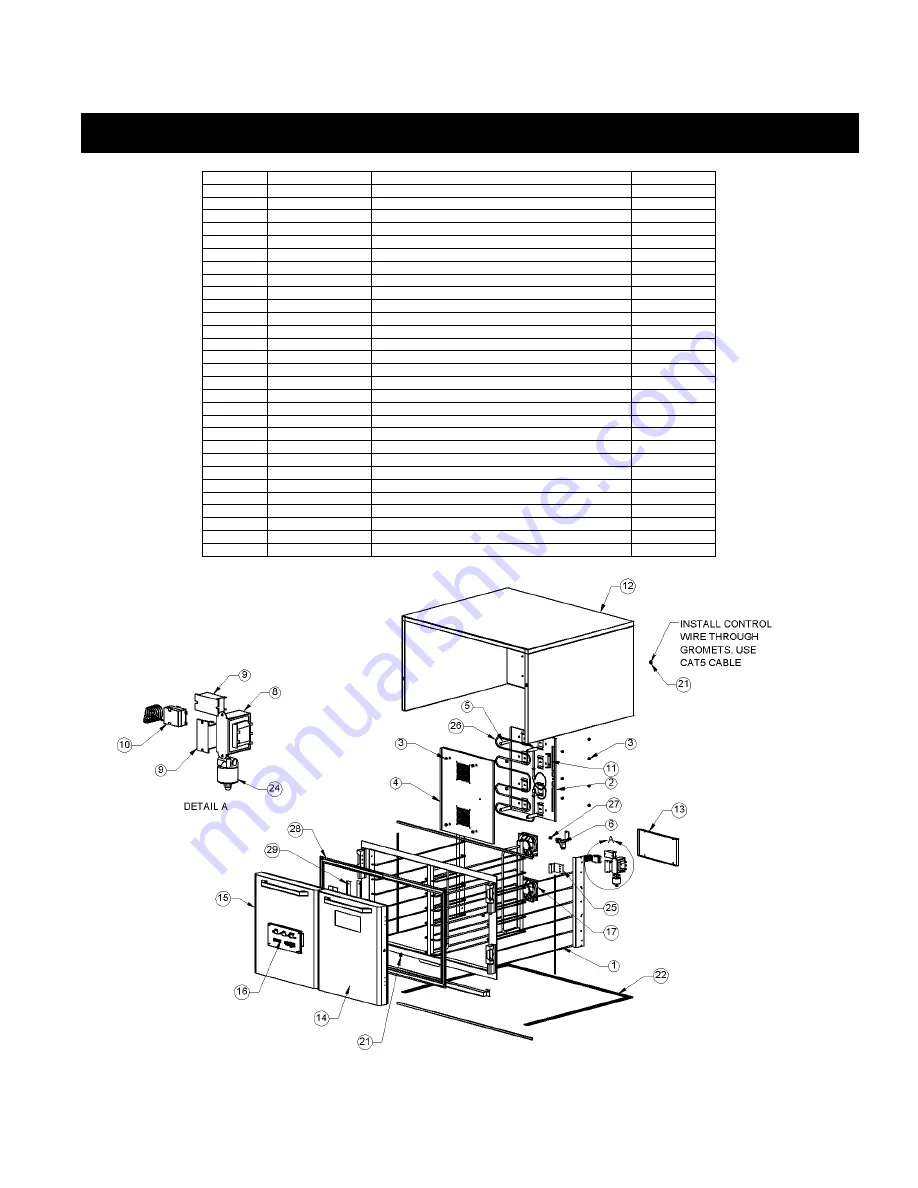

ILLUSTRATED PARTS BREAKDOWN

.

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

151-756

Frame Assembly-Proofer

1

2

151-767

Heated Plate Assembly

1

3

20101-02

Hex Cap Nut 8mm

16

4

151-422b

Panel, Proofer w/Fan Holes

1

5

151-421

Spacer, Panel-Proofer

4

6

151-768

SPRAY NOZZLE WELD ASSY

1

7

70101-23

ELBOW 1/4 NPT X 8m CC

1

8

31400-32

TRANSFORMER 115V/24V 100VA

1

9

30701-05

CONTACTOR 2 POLE 30A 24 VAC

2

10

30401-27

Hi-Limit Thermostat, 100 C

1

11

151-428

Mount, Hi-Limit Bulb _Proofer

1

12

151-755-1

Box Assembly-Proofer

1

13

151-429

Cover, Electrical-Proofer

1

14

151-757-2

Door, RH-Proofer

1

15

151-757-1

Door, LH-Proofer

1

16

40102-71

Control Assembly, Mini Proofer

1

17

30200-45

MOTOR W/ FAN AXIAL 115VAC 70 C

2

18

72801-24-33

Foam Tape, 839mm

4

19

72801-24-42.3

Foam Tape,575mm

2

20

72801-24-22.68

Foam Tape,575mm

2

21

70801-11

Grommet, Rubber

3

22

72801-24-37.6

Foam Tape, 955mm

2

23

151-772

Drip Tray, Proofer

1

24

70403-01

Solenoid Valve, 3/8"

1

25

151-427

Mount,Hi Limit-Proofer

1

26

11092-01

Heating Elements

1

27

70101-75

Spray Nozzle

1

28

72602-211-20

Magnetic Door Gaskets

2

29

151-132

Center Door Sweep

2