15

7. CLEANING AND MAINTENANCE

1)

Use the wet cloth to clean the machine after daily use, do not wash it with water

directly.

2)

Clean the splashed flour thoroughly which may lie in the top of the clamping block,

safety cover, etc.

3)

Clear the dust in the top cover of the spiral mixer very often.

4)

Make sure to turn off the power after daily use.

5)

Check all the components to see whether it is in good status termly.

6)

Check whether the convection belts are in good tension monthly.

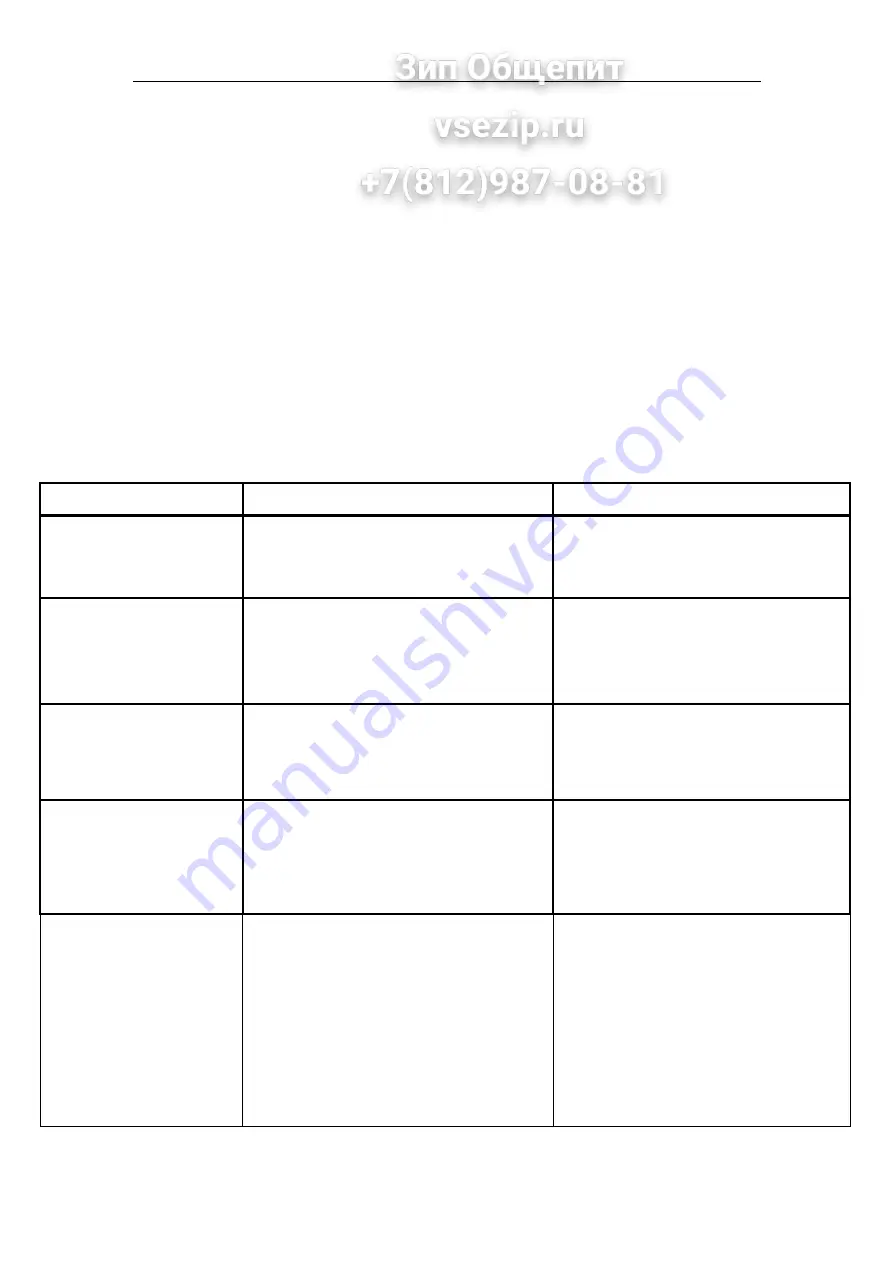

8. TROUBLESHOOTING

Item

Possible reason

Method

1.Bowl and beater rotate in

reverse direction

Check whether the any of the two cables

are in reverse connection

exchange any of the two cables

2.Machine shakes when

operation

a)

The ground is not horizontal and

plain enough.

b)

Foot pad is unstable.

a)

Select a horizontal and plain

ground to install it.

b)

Readjust the foot pad to enable the

machine’s stability.

3.The bowl still rotates

after the safety cover has

been opened

a)

The microswitch is wrong.

b)

The adjust wheel go with the

microswitch is wrong

a)

Change the microswitch.

b)

Tighten the adjust wheel or change

it if damaged.

4.Guide roller can’t work

a)

The bearing of the guide roller is

damaged.

b)

The gap is too long to service the bowl

a)

Change the microswitch.

b)

Readjust the gap between guide

roller and bowl to satisfy the bowl.

5. Main shaft can not work

a)

Check the power

b)

Check the main switch

c)

Check the motor

d)

Check the magnetic valve

e)

Check the over-load protection

f)

Check any breakage about “ON/OFF”

button.

g)

Check the trolley whether well located

Should carried on professional

electricians

.

Summary of Contents for SM-120a

Page 17: ...17 9 ELECTRIC DIAGRAM ...

Page 18: ...18 10 PARTS LIST ...