B. Smooth R(Be the same with:

MIIL_MS

、

MIIL_M)

19

7. Enter the start angle of the circular arc

(ST ANG)

This determines the position of the first cut feed in the processing of circular arc.

As show in Fig.(b), the start angle is 0° if the arc is to be processed from Point E

to Point F, and 90° when from F to E.

8. Enter the end angle of the arc

(ED ANG)

This determines the position of the last cut feed in the processing of circular arc.

As shown in Fig. (b), the end angle is 90° if the arc is to be processed from Point E

to Point F, but 0 when from F to E.

9. Determine inner/outer circle mode:

For outer circular arc, as shown in Fig. (b), RAD+TL.

For inner circular arc, as shown in Fig. (c), RAD -TL.

10. Move the machine tool to the start point of the processing in

following with the display on axes, and then start the point by point

processing.

11. You can quit the Arc R Calculation function as will, just key .

(

Ⅰ

) *Take the processing of the arc shown in the figure in page 22 as an

example.

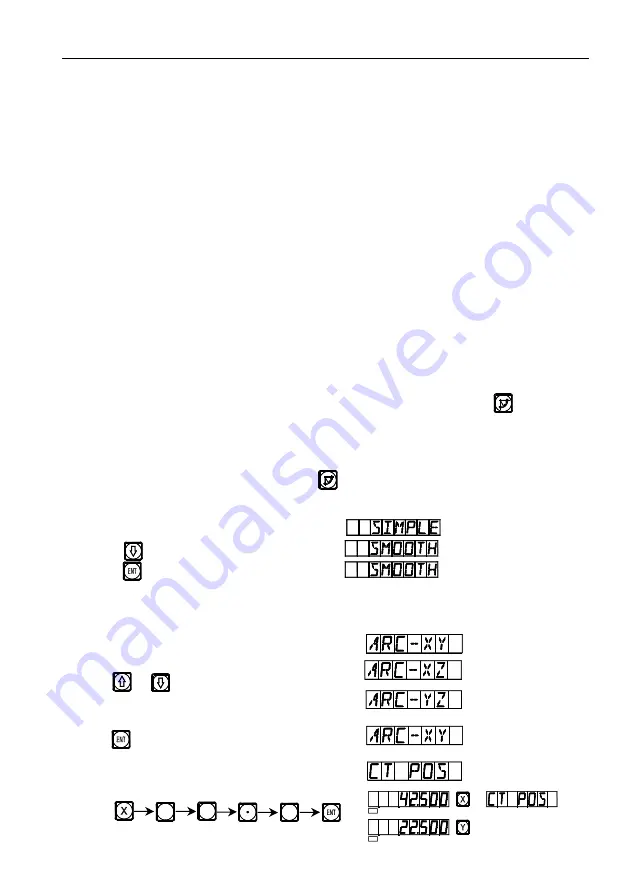

1) At first, finish tool setting, reset, key ,

and enter ARC function.

2)choose smooth function

press

press

(

only 2V readout has this set item and 3V readout has only smooth R function

,

so hasn’t the set item and directly get into next step

)

3) Select processing plane

Key or

4) Select Plane XY

Key

5) Enter the position of the circle center.

If finish the tool setting as shown in Fig. (a).

Key

R

R

2

4

5

SEL

SEL

Summary of Contents for SDS6

Page 1: ...SINO DIGITAL READOUTS SDS6 Operation Manual GUANGZHOU LOK SHUN CNC EQUIPMENT LTD ...

Page 10: ...A Basic Function 1 A Basic Functions ...

Page 24: ...B Smooth R Be the same with MIIL_MS MIIL_M 15 B Smooth R Be the same with MIIL_MS MIIL_M ...

Page 86: ...J 200 Tool Storeroom Be the same with LATHE 77 J 200 Tool Storeroom Be the same with LATHE ...

Page 104: ...N N3 Function Be the same with 2V MIIL_MS 95 N N3 Function Be the same with 2V MIIL_MS ...