10

GETTING TO KNOW YOUR LOG SPLITTER….cont

Always operate your log splitter on dry, solid, level ground. Never operate

your log splitter on slippery, wet, muddy, or icy surfaces. The location you

choose should be free from any tall grass or other interferences. There

should be plenty of room for handling. Keep your work area clean and

tidy as much as possible. Cluttered areas invite injuries. To avoid tripping,

do not leave tools, logs, or other components laying around the work ar-

ea. Do not use the log splitter in wet or damp areas or expose it to rain. Do

not use it in areas where fumes from paint, solvents or flammable liquids

pose a potential hazard.

Any log splitter may throw foreign objects into the eyes, this can cause per-

manent eye damage, always wear safety goggles, everyday eyeglasses

have only impact resistant lenses, they are not safety glasses.

Take used oil to an authorized collection point or follow the stipulations in

the country where the log splitter is used. Do not discharge into drains, soil

or water.

Unplug when not in use, before making adjustments, changing parts,

cleaning, or working on the log splitter.

Check your log splitter before turning it on. Keep guards in place and in

working order. Form a habit of checking to see that any adjusting tools

etc. are removed from machine and work area before turning it on. Re-

place damaged, missing or failed parts before operating the log splitter.

Make sure all nuts, bolts, screws, hydraulic fittings, hose clamps, etc. are

securely tightened. Always check the oil level in the hydraulic oil tank. Nev-

er operate your log splitter when it is in need of repair or is in poor me-

chanical condition.

Read and understand the owner’s manual and labels affixed to the log

splitter. learn its application and limitations as well as the specific potential

hazards peculiar to it.

Warning Labels Attached To The Log Splitter:

15

Grease

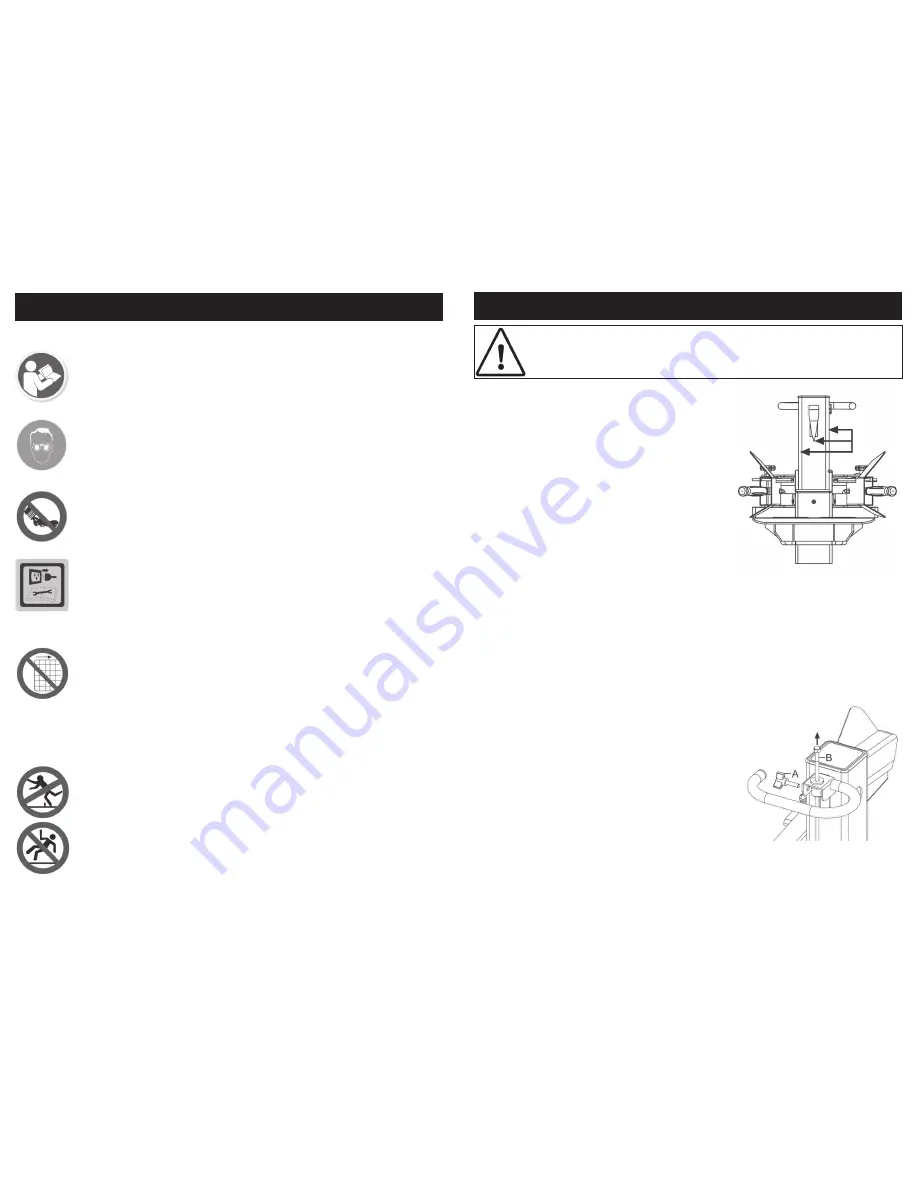

3. Apply a thin coat of grease to the surfaces of

the ram as shown.

4. Route the mains lead from the power source to

the splitter in a way that safeguards against trip-

ping on the cord.

5. Loosen hydraulic oil filler cap a few turns when-

ever the splitter is being used (retighten when

you have finished using the log splitter).

6. Start the log splitter and leave running for about

15 minutes to preheat the hydraulic oil.

7. Before initial operation, ensure the two-handed

operation is correctly functioning by following

steps:

OPERATING INSTRUCTIONS….cont

a) Lower both control levers, the splitting wedge will lower.

b) Release either of the levers, the splitting wedge should remain in the original

lowered position.

c) Release both levers, the ram should rise to the highest position automatically.

It is possible to set the height of the cutting wedge to match the logs to be cut; this will

reduce down time as the ram will not have to return fully to the top of its stroke.

8. To set the wedge ram stroke, take the following

steps:

a) Move the splitting wedge to desired position,

the upper position of the ram wedge travel

should be about 3-5cm over the logs to be

split.

b) Release one of the control levers or switch off

motor.

c) Loosen the setscrew (A), raise the adjusting rod

(B) until you feel resistance then tighten the

setscrew (A).

d) Release both control levers or switch on motor.

e) Check the upper position of the splitting

wedge.

CAUTION:

Do not attempt to split logs that are too “green.” Dry, seasoned

logs split much more easily, and will not jam as frequently as green wood.