14

TROUBLESHOOTING

Symptom

Possible Causes

Corrective Action

Jack will not lift load.

Release valve not tightly closed.

Pump has lost it’s prime.

Load is too heavy.

Air supply not sufficient.

Ensure release valve tightly closed.

See ‘priming the pump’.

Consider higher capacity jack.

Check air supply.

Jack will lift, but not

maintain pressure.

Release valve not tightly closed.

Hydraulic unit malfunction.

Ensure release valve tightly closed.

Discontinue use, contact supplier.

Jack will not lower after

unloading.

Reservoir overfilled.

Release valve not fully open.

Linkages binding.

Low oil level.

Drain oil to proper level.

Ensure release valve is fully open.

Clean and lubricate moving parts.

Ensure proper oil level.

Low oil level.

Air trapped in system.

Air supply not sufficient.

Ensure proper oil level.

See ‘bleeding the jack’.

Check air supply.

Poor lift performance.

Will not lift to full extension.

Low oil level.

Air supply not sufficient.

Ensure proper oil level.

Check air supply.

7

TECHNICAL SPECIFICATIONS

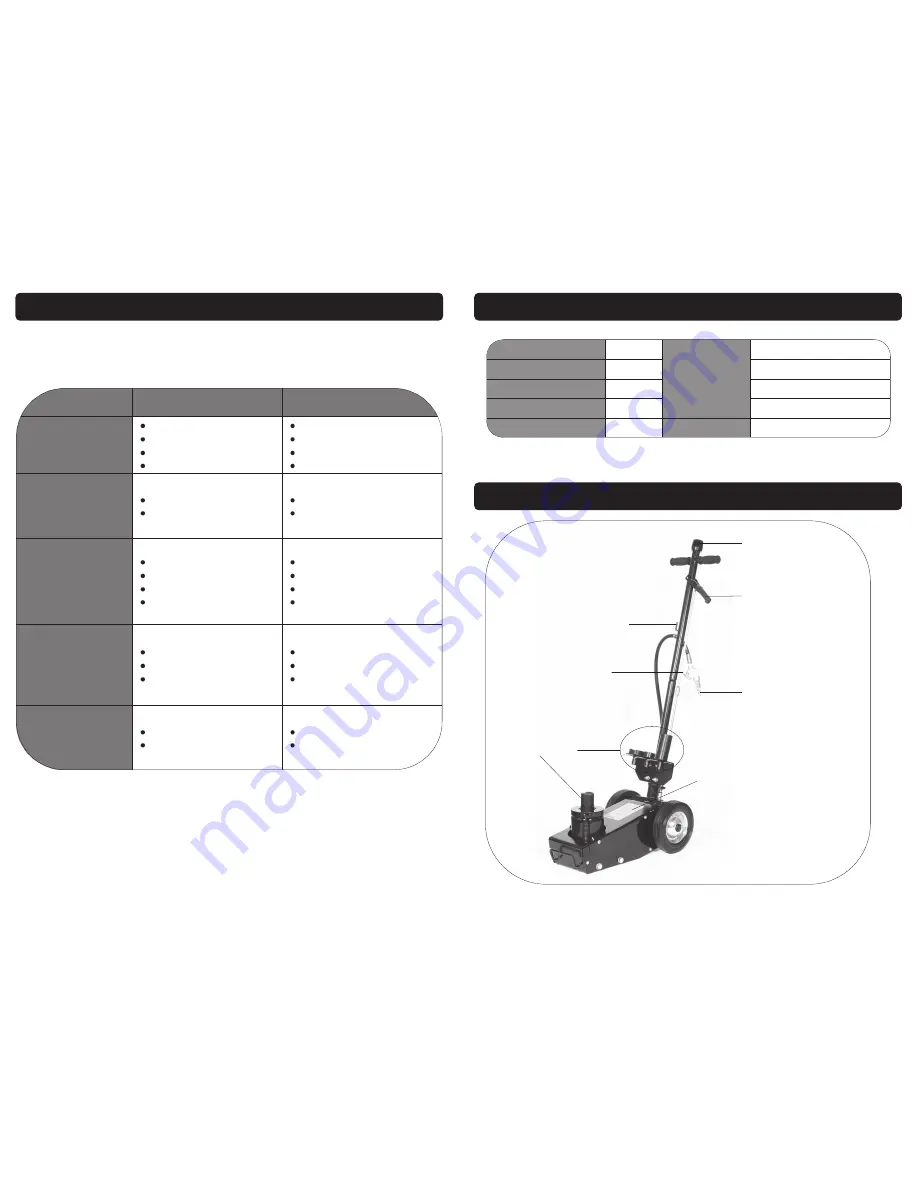

Release Valve

Handle Release / Lock

Air Inlet

Height Adaptors

Air Control Valve

Airline Hook

Cover

GETTING TO KNOW YOUR JACK

Lifting Capacity

22 Ton

110 x 50 mm

Ø

Adaptor sizes

Minimum Height

230 mm

50 x 50 mm

Ø

Ram Stroke

120 mm

20 mm x 50 mm

Ø

Screw Extension

115 mm

20 mm x 70 mm

Ø

Air Pressure

7 - 10 bar

Net. Weight

46Kg