14

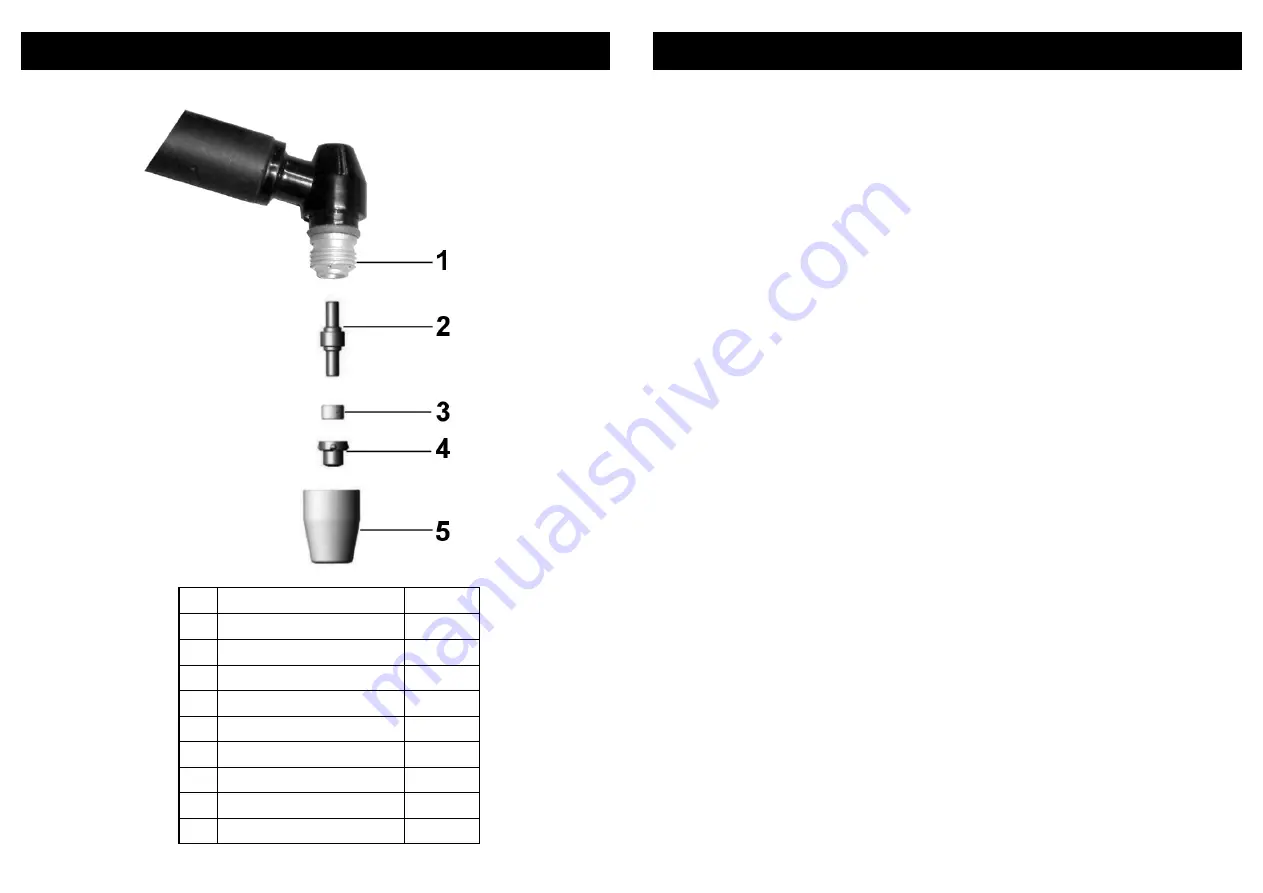

TORCH CONSUMABLES

1

TORCH COMPLETE

05516

2

ELECTRODE SHORT

05184

2

ELECTRODE LONG

05193

3

TIP SWIRL BAFFLE

05185

4

TIP SHORT

05186

4

TIP LONG

05196

5

SHEILD CUP

05188

Ref

DESCRIPTION

SIP CODE

2-5

CONSUMABLE SET SHORT

05190

2-5

CONSUMABLE SET LONG

05198

7

SAFETY….cont

FIRE AND EXPLOSION PREVENTION

1. Causes of fire, and explosion are: Combustibles reached by the arc, flame, fly-

ing sparks, hot slag or heated material, misuse of compressed gases and cylin-

ders, and short circuits. BE AWARE THAT: flying sparks or falling slag can pass

through cracks along pipes, through windows or doors, and through wall or floor

openings and out of sight of the operator. Sparks and slag can fly up-to 35

feet.

2. Keep equipment clean and operable, free of oil. grease, and (in electrical

parts) of metallic particles that can cause short circuits

3. If combustibles are in the area. DO NOT weld or cut, move the work if practical

to on area free of combustibles. Avoid paint spray rooms, dip tanks, storage ar-

eas, ventilators. If the work can not be moved, move combustibles at least 35

feet away out of reach of sparks and heat, or protect against ignition with suit-

able and snug fitting, fire-resistant covers or shields.

4. Walls touching combustibles on opposite sides should not be welded on (or

cut). Walls, ceilings, and floor near work should be protected by heat resistant

covers or shields.

5. A fire watcher must be standing by with suitable fire extinguishing equipment

during and for some time after welding or cutting if:

A. Appreciable combustibles (Including building construction) are within 35 feet.

B. Appreciable combustibles are further than 35 feet but can be ignited by sparks.

C. Openings (concealed or visible) In floors or walls within 35 feet may expose

combustibles to sparks.

D. Combustibles adjacent to walls, ceilings, roofs. or metal partitions can be ig-

nited by radiant or conducted heat.

6. After Work is done, check that area is free of sparks, glowing embers, and

flames.

7. An empty container that held combustibles. Or that can produce flammable or

toxic vapors when heated, must never be welded on or cut, unless container

has first been cleaned as described in AWS Standard A6.0 listed 3 in Standards

Index. This includes a thorough steam or caustic cleaning (or a solvent or water

washing, depending on the combustible’s solubility) followed by purging and

inserting with nitrogen or carbon dioxide, and using protective equipment as

recommended in A6.0 Water filling just below working level may substitute for

Summary of Contents for 05175 Plasma 46

Page 2: ...2 19...