14

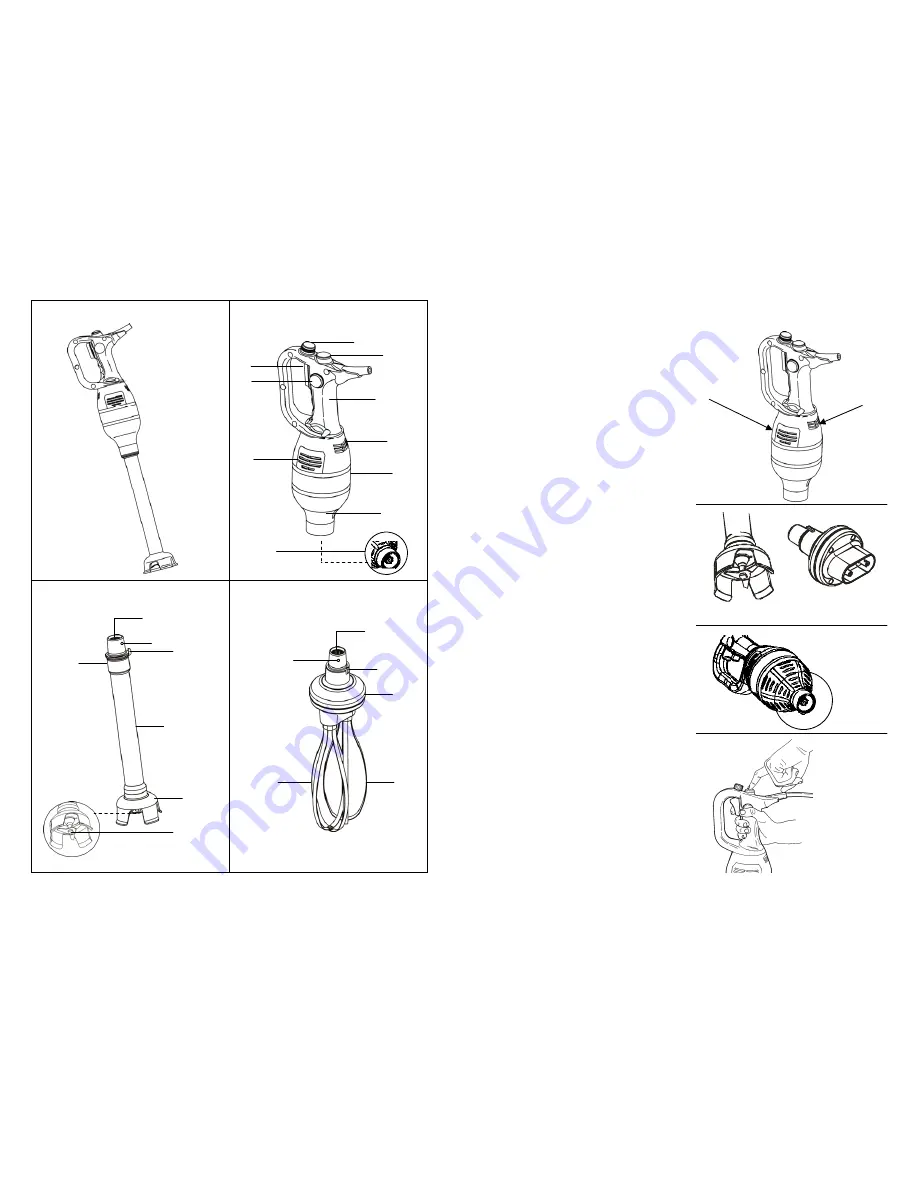

Fig. n°30

Dipping blender

Engine’s

body

Operating shaft

Operating

whip

12

14

15

16

11

13

17

12

14

13

18

19

19

01

02

03

04

05

06

10

09

07

08

15

Fig. n°33

4.2 - IN-BUILT SAFETY DEVICES

4.2.1 - Mechanical safety devices

As far as mechanical-nature safety, the

dipping blender described by this man-

ual complies to:

-

the

EC 2006/42

machine’s directives

The dipping blender is provided with:

-

Whip-protecting bell (Fig. 32 –ref.b)

-

Shaft-protecting bell (Fig. 32 – ref.a)

-

Dragging device inserted engine’s

stem (Fig. 33)

-

Anti-accidental switching handle

(Fig. 34)

-

Respect of the minimum space to

grip the machine as per what is pre-

scribed by law

-

Maximum liquid level marked on the

shaft (Fig. 45)

4.2.2 - Electrical safety devices

As far as electrical-nature safety, the

dipping blender described by this man-

ual complies to:

-

the

EC 2006/95

low tension directive

-

the

EC 2004/108

electro-magnetic

compatibility directive

Therefore the dipping blender is pro-

vided with:

-

Double-insulating system to guaran-

tee that all the details that might

come in contact with the operator

are not subject to tension not even

in case of breakdown.

-

Safety device against accidental

switching on (Fig. 34)

-

Internal components protection from

liquid splashes

Fig. n°34

Aspiration

grill air

Escape grill

air

Fig. n°32

(a)

(b)

Fig. n°31