24

ter and where necessary with the

previously used detergent (Fig. 57).

5) Empty the container, rinse it and fill

it with warm water. Let the machine

operate again for some more 10-15

seconds, if necessary repeat the op-

eration till a complete and thorough

rinse is guarantied.

6) ATTENTION: Check the result of the

operation and if necessary repeat

from point (2) or intervene manually

on the parts that are still dirty. The

knives area could provoke wounds

to the hands (Fig. 56). So, please

pay the maximum attention.

7) Reuse the tool for another operation

or:

8) Dry the tool with a cloth and position

it vertically for 1 or 2 hours to ease

the drainage of residual liquid (Fig.

57).

9) Hence place the shaft on the special

wall bearing (Fig. 58).

WHIP

(Fig. 59)

Proceed as described for the shafts till

point 5.

6) disassemble the whip from the

whip’s body and check the complete

cleaning.

Intervene manually on the parts that

are still dirty, paying attention to the

internal area of the whip’s body (Fig.

60)

ATTENTION:

Whips can be danger-

ous when handles with bare or wet

hands. Wear protective gloves and

pay maximum attention anyway.

Reuse the tool for another operation

assembling the whips to the whip’s

engine or:

7) Dry the whip’s body with a cloth po-

sition it vertically for 1 or 2 hours to

ease the drainage of residual liquid

(Fig. 58).

8) Hence place the assembled whip on

(1) (2)

(3) (4)

(5)

ATTENTION!

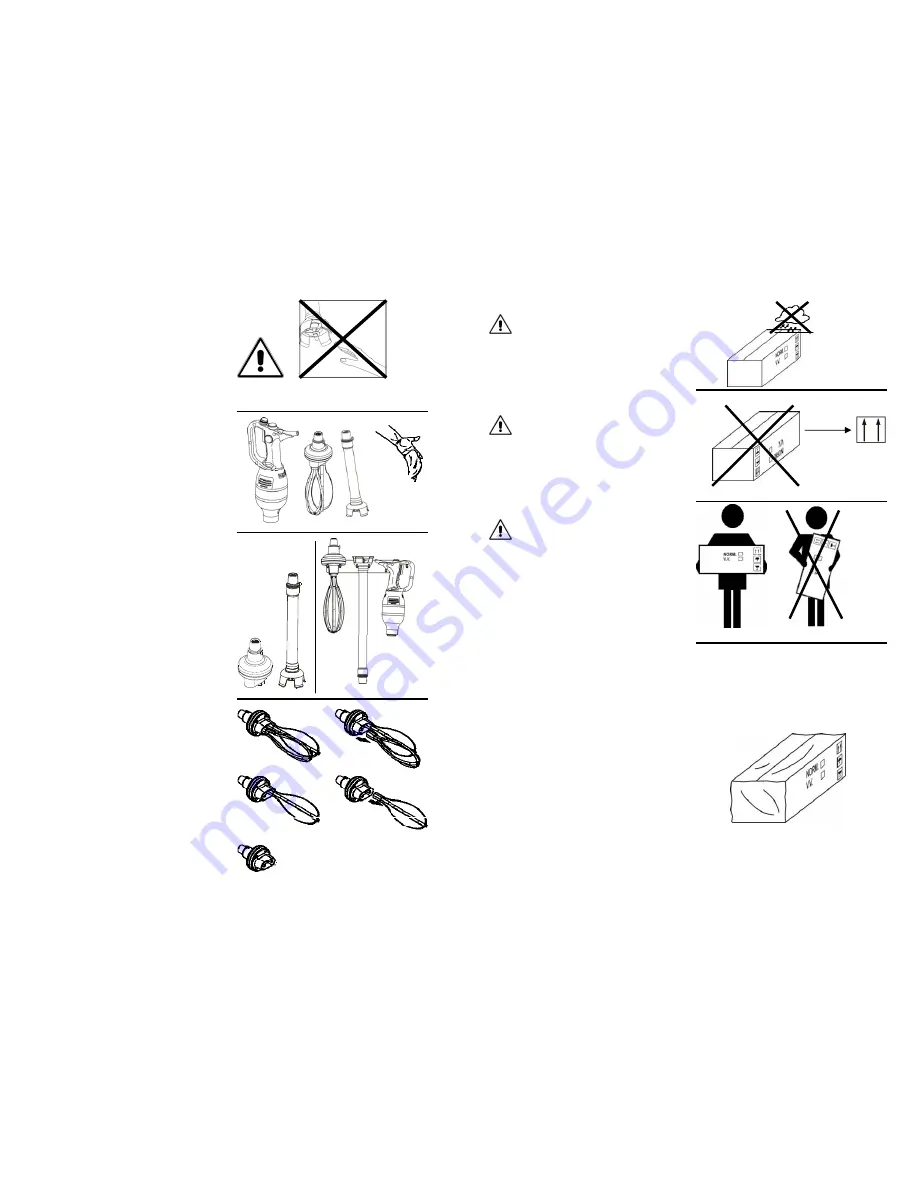

Fig. n°56

Fig. n°59

Fig. n°58

Fig. n°57

a)

b)

5

Once the item has been received, pro-

ceed to the opening and check that all

the material is inside if the box does not

show external damages. While if the

box or the contents show signs of mis-

using (Fig. 6), knocks, fall or ruptures, it

is necessary to inform the freight for-

warder of the damage by writing a de-

tailed report about the possible dam-

ages suffered within three days of the

delivery date. Generally, complaints

that are not communicated immediately

are not taken into consideration by the

freight forwarder.

1.2 - BOX CHECK UPON RECEIPT

Do not overturn the box (Fig. 4).

Please ensure that the box is held

firmly at the far ends of its longest

sides, while carrying it and keep the

box itself parallel to the floor (Fig. 5).

Do not leave the box exposed to hu-

midity and rain (Fig. 3).

Fig. n°3

Fig. n°5

Fig. n°4

Fig. n°6