SIRS NAVIGATION LTD

COMPONENT MAINTENANCE MANUAL

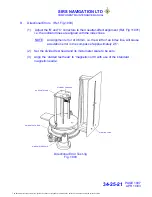

The compass bowl is filled with silicone fluid to control movement of the compass

card. Bellows (10) at the rear of the compass bowl, allow fluid volume changes.

A filling plug (190), disc (210) and washer (200) are assembled to the compass bowl

below the corrector assembly (160). A marked scale, on the front edge of the

corrector assembly gives a guide for coefficient 'A' correction.

The magnetic correctors, for coefficients 'B' and 'C', are small bar magnets installed

in the gear shafts of the corrector assembly. ‘Indicator lines’ on the end of the gear

shafts identify the direction of the magnets. Gear shaft movement can be seen on

top of the corrector assembly as an angular difference between the indicator lines

and the marked index lines. The magnetic correctors are adjusted with a corrector

key (220) that is turned inside the corrector adjustment holes, at the front of the

compass bowl.

The lamp housing assembly (230) is a plastic moulding that is assembled to the

base of the bowl and secured with a clip-fit procedure

.

A lead and socket assembly (260) is assembled to the underneath of the lamp

housing assembly.and gives electrical connection.

A ‘non-magnetic’ lamp (240) is installed into a spring inside the lamp housing

assembly and is retained by the lamp cap (250).

D. Operation

The compass operates without an electrical power supply. The magnet of the

compass card is aligned with the earths magnetic field. The direction of the aircraft

is determined with reference to a vertical lubber line positioned close to the compass

card.

Magnetic corrector magnets, at the top of the compass, can be adjusted to cancel

magnetic forces induced by the aircraft.

A light fitted at the bottom of the compass is used to light up the compass card.

PAGE 2

APR 10/03

34-25-21

The document reference is online, please check the correspondence between the online documentation and the printed version.