SIRS NAVIGATION LTD

COMPONENT MAINTENANCE MANUAL

F. Filling (Ref. Fig. 7003)

NOTE: The procedure must be done at a temperature of 20

°

C

±

2

°

C.

(1) Attach the hooked rod of the bellows setting jig 3255 LMT to the lug on the

bellows

(10).

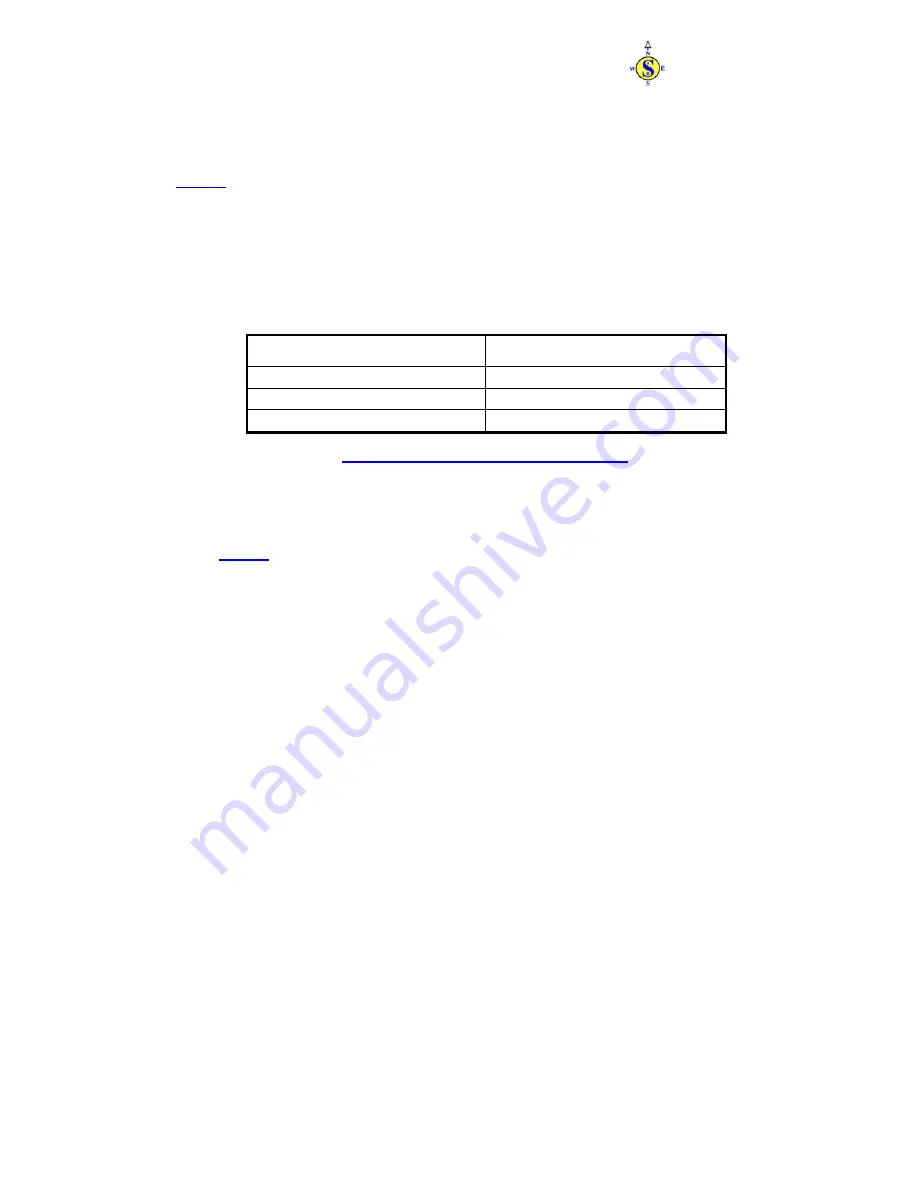

(2) Assemble the correct spacer, shown in the table 7001, between the jig and the

bellows.(Ref. Fig 7002).

Fluid temperature (°C)

Length of spacer

18

8.5mm (0.334”)

20

8.9mm (0.350”)

22 9.4mm

(0.370”)

Bellows Setting Spacer- Table 7001

(3) Turn the knurled nut on to the hooked rod until the spacer is lightly compressed

between the bellows face and the jig bar.

NOTE:

The procedure that follows is an example of how to fill the compass

bowl with fluid. Alternative equipment can be used if it does the same task.

(4) Assemble the ‘Silicone Fluid Container’ (SFC-1) to the compass bowl.

(Ref. Fig. 7002).

(5) Put the assembly into a vacuum chamber and fill the silicone fluid container

with 50ml of clean silicone fluid. The bowl must be sloped at an angle of 5

°

horizontal to aid removal of air bubbles.

(6) Lower the pressure of the vacuum chamber to 6.78 Kpa A (2 in. Hg A) for a

time of approximately 30 seconds. This will remove most of the air in the

compass.

(7) Increase the pressure to atmospheric level and add more silicone fluid to the

silicone fluid container to make sure the filler plug hole is full.

(8) Lower the pressure of the Vacuum chamber to 13.55 Kpa A (4 in Hg A) for a

time of approximately 1.5 hours to remove all of the remaining soluble air.

PAGE 7005

APR 10/03

34-25-21

The document reference is online, please check the correspondence between the online documentation and the printed version.