注意:

1.

使用新機器最初一個月

(

約

200

小時

)

應以

最高縫紉速度之

80%

運轉後,再用出廠速度

運轉,能增加縫紉機壽命

(

表

1)

,並請選擇

正確的馬達皮帶輪尺寸。

(

表

2)

2.

皮帶輪轉動方向為逆時針。

(

圖

2)

3.

桌板厚度約

45mm

。

4.

馬 達 規 格: 離 合 器 馬 達,

3

相

2

極

400

瓦

(1/2HP)

。

5.

電壓

:110V

,

220V

,

380V

。

6.

皮帶規格:

M

型

V

字皮帶。

潤滑油之注入與更換

LUBRICANT OIL FILLING AND

REPLACEMENT

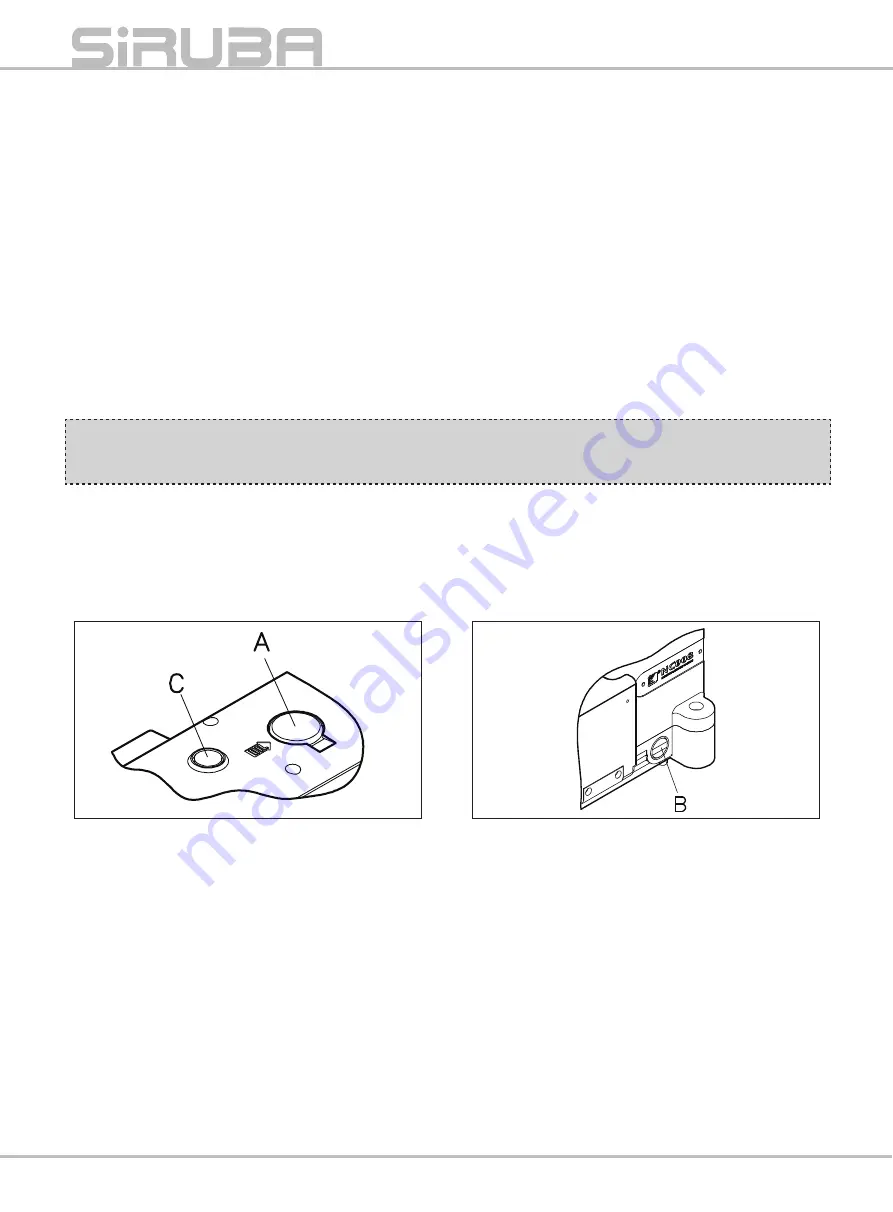

圖

3/Fig 3

圖

4/Fig 4

1.

潤滑油之注入:

(

圖

3.4)

*

打開注油口的油帽

(A)

,加入潤滑油直至由

窗

(B)

內之油標線中間即可,然後再蓋上

(A)

,加完油後轉動一下縫紉機,確認一下

油是否能打到油鏡

(C)

處。

Remarks

:

1.New machines run a speed at approximately

80% of the Maximum speed in the first month

(Table 1). Be sure to choose proper motor

pulley for your machine(Table 2).

2.The motor pulley

turns counterclockwise(Fig.2)

3.Thckness of Table Top is about 45mm.

4.Specification of motor

:

Clutch motor 3

Phase, 2 poles, 400w (1/2 HP).

5.Voltage : 110V

,

220V

,

380V.

6.Driving Belt:M type,V belt.

1.To fill lubricant oil: (Fig. 3.4)

*Loosen Knob (A), fill in with lubricant oil or

its equivalent such as Mobil #10 or Esso

#32. Please fill the oil up between two level

lines on oil lndicator (C) and tighten Knob

up.

新機器運裝前均已將油倒盡,因此機器使用前

必須加入潤滑油。

請使用超高速潤滑油或

MOBIL#10

或

SSO#32

等級之潤滑油。

Machine chamber is empty with no oil. Please

fill lubricant oil into new machines before

running.

P l e a s e c h o o s e w i t h l u b r i c a n t o i l o r i t s

equivalent such as Mobil #10 or Esso #32

P9

Summary of Contents for NC008

Page 1: ...NC008 INSTRUCTIONS BOOK PARTS LIST...

Page 27: ...P24...

Page 28: ...P25...

Page 29: ...P26...

Page 30: ...P27...

Page 31: ...P28...

Page 32: ...P29...

Page 33: ...P30...

Page 34: ...P31...

Page 35: ...P32...

Page 36: ...P33...

Page 37: ...P34...

Page 38: ...P35...

Page 39: ...P36...

Page 40: ...P37...

Page 41: ...P38...

Page 42: ...P39...

Page 43: ...P40...

Page 44: ...P41...