Optional Equipment

16---3

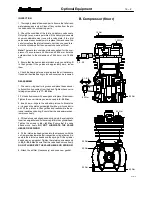

C. Industrial clutch (A.P. Borg &

Beck)

SERVICE

Note! Never service or adjust the clutch with the engine

running.

1

2

3

4

216--- 3

1. Inspection cover

2. Pull---out hole

3. Grease nipple for release bearing

4. Grease nipple for main bearing

1. Lubricate the release bearing daily and the main bearing at

intervals of 50 running hours. Use lithium---based grease for

lubrication (e.g. Shell Alvania no. 2).

2. At intervals of 500 running hours lubricate the wrist pins, the

yoke ends and the cross shaft bearings with a few drops of en-

gine oil.

ADJUSTMENT

The clutch is correctly adjusted when the engagement load at

the end of the operating lever is

34...41 kg

(operating lever

length 63,5 cm).

Adjusting rings of the clutch

216--- 4

1. Remove the inspection cover and release the adjuster lock

on the red adjusting ring.

216--- 5

Note!

Some clutches have a socket headed screw to lock the

adjusting ring. Remove the screw before adjusting. After ad-

justment tighten the screw to

13,5...18 Nm

and ensure that

the inner end of the screw engages between the splines on

the body.

2. Turn the adjusting ring clockwise by hand or by tapping with

a light hammer, until the correct adjustment is reached.

3. Fit the adjuster lock and the inspection cover.