1)

2)

1)

Increase in air pressure

May be caused by air supply system that is

inadequate for application to rise as other

plant equipment is shut down This causes

more air available to operate pump with

Unauthorized tampering with air pressure

regulator may also be cause

Increase in demand

Fluid demand may be greater than expected

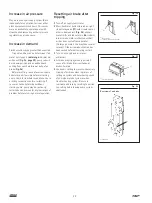

Tripped condition can be determined if air

motor has stopped,

red/orange

indicator pin

will be out (

Fig. 14

,

page 10

), pump rod will

be in down position and air will be heard

venting from vent hole in lower body of air

brake (

Fig. 16

)

Before resetting, cause of overrun should

be determined if possible before restarting

pump Check for low fluid levels, broken hose

or fitting connections before restarting If

cause cannot be determined without

starting pump, pump may be cautiously

restarted and observed for any indications of

problem before resuming normal operation

Resetting air brake after

tripping

1

Turn off air supply to air motor

2

Press flush reset button (located on right

side of relay valve (

17

) with screwdriver or

other suitable object, (

Fig. 15

), until air

motor shifts and Indicator pin (

48

) retracts

into air brake Hold reset button until all

air has been vented from air motor

(On large air motors this may take several

seconds) Otherwise wait until all air has

been vented before attempting restart

3

Turn on air supply and air motor

will restart

4

Air brake may trip again very quickly if

cause of air brake trip is cavitation or

broken fluid line

5

Use bypass setting to prevent unnecessary

tripping of air brake when in process of

setting up system and determining speed

of pump/pump tube system or when

trouble shooting system Be sure to

reactivate air brake by resetting to desired

run setting before leaving pump system

unattended

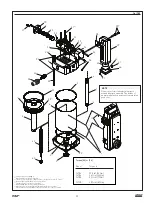

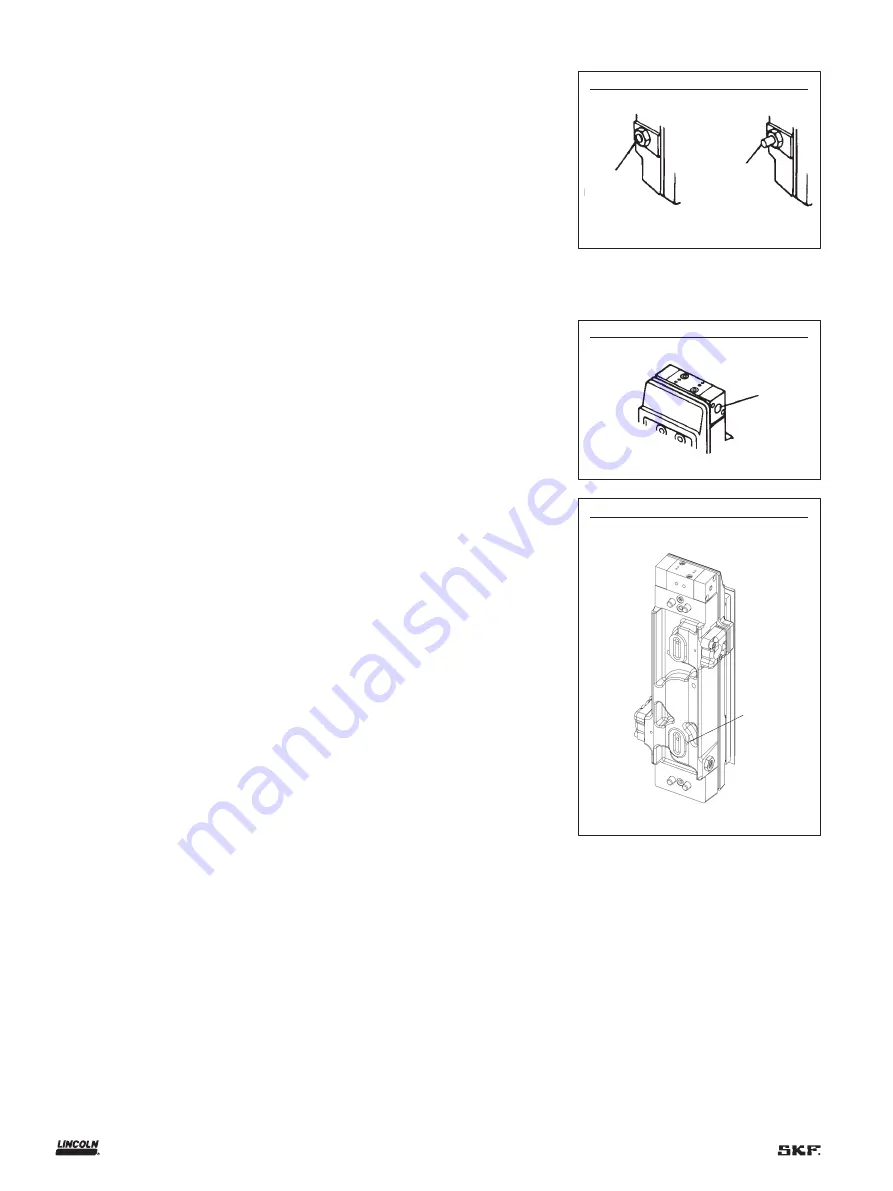

1)

Fig. 14

1)

Run position

2)

Tripped condition (extended)

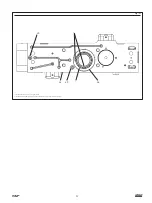

1)

Flush reset button

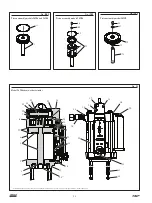

1)

Vent hole

Fig. 15

Fig. 16

Rear view of air brake

10