Troubleshooting

Problem

Possible cause

Solution

Air motor is not operating, air is coming

from exhaust

Inadequate air supply to air motor

Check air supply and adjust to minimum

recommended level Check air supply hose

and piping for minimum recommended size

Ensure FRL and quick disconnect couplings

meet or exceed minimum specified sizes and

do not restrict airflow to air motor

Erratic or accelerated operation with short

stroking Air motor hesitates on up or down stroke

Dirty or damaged relay valve (

17

) or air signal

valve (

20

) or stop valve assembly (

60

)

Check valves and clean if necessary

Replace any damaged seals or worn parts

Pump cavitation

Check fluid level Ensure pump inlet is not

blocked or restricted or is large enough to

handle flow into pump inlet

Air brake trips off even though air motor is

operating below set trip speed (trips after

three or more strokes)

Dirty or blocked labyrinth plate or components

Clean or replace labyrinth components

Check for grease or oil blocking air passages

in labyrinth subassembly Blocked labyrinth

may be confirmed (in quiet locations) by

turning selector knob to

RUN

mode setting

immediately after air motor has stopped If sudden

rush of air escaping is heard, labyrinth

is either blocked or installed incorrectly

Grease or dirt on balls (

81

) in labyrinth cover (

78

) Clean balls and labyrinth cover with solvent

Coat with very light film of light grease to hold balls

in cover

Air brake trips even though air motor is

operating below set trip speed (within

three strokes)

Leaking diaphragm (

58

)

Replace diaphragm

Leaking upper gasket (

51

)

Replace upper and lower gaskets (

51

and

53

)

Upper piston quad ring (

64

) is leaking

Replace quad ring

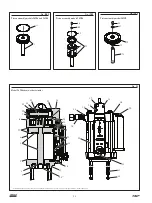

Laminated labyrinth plate (

77

) is installed

incorrectly

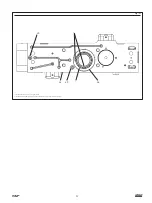

Observe laminated labyrinth plate and find

single hole (

76

) and align with hole (

75

) (

Fig. 3

)

Air brake trips at proper speed (as

indicated by sound of air surging into

diaphragm chamber), but air motor

does not stop Indicator pin does not

pop out

Stop valve vent hole in lower body (

54

) is clogged

or blocked (

Fig. 17

)

Unclog vent hole in lower body

Stop valve (

60

) is damaged

Check stop valve and replace if worn or

damaged

Diaphragm seal is damaged, worn, deformed or

improperly installed

Replace damaged or worn diaphragm seal

If not damaged, reinstall into diaphragm (

58

)

with twisting action to fully seat in mating hole

Inadequate air supply to air motor

See above for checking air supply Ensure that

air regulator is set to air pressure at or greater than

minimum recommended air pressure for

air motor installed

Air brake will not trip even though air motor

has been running above trip speed for more

than 1 minute

Discharge umbrella valve (

63

) is damaged or worn Replace both umbrella valves

Diaphragm seal is damaged, worn deformed or

improperly installed

Replace damaged or worn diaphragm seal

If not damaged, reinstall into diaphragm (

58

)

with twisting action to fully seat in mating hole

Leaking upper gasket (

51

) or lower gasket (

53

)

Replace gaskets (

51

and

53

)

Stuck metering pump piston (

55

)

Install air pump repair kit, replacing items

55

,

56

,

63

,

64

and

65

Inlet air filter (

40

) is completely or partially clogged Clean or replace inlet air filter

19